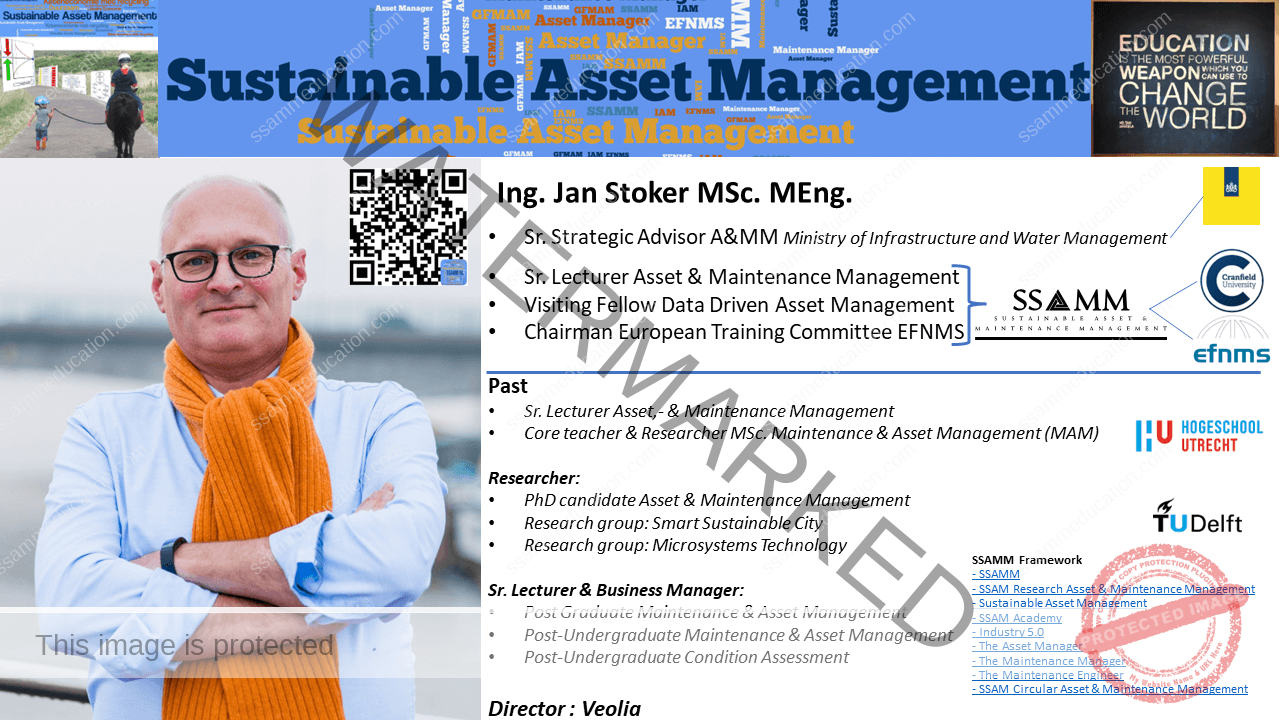

Date: February 2025, Authors & Review: SSAMM, Review: J. Stoker Follow Jan Stoker

The online version of the presentation.

Follow Jan at Linkedin for updates and more:

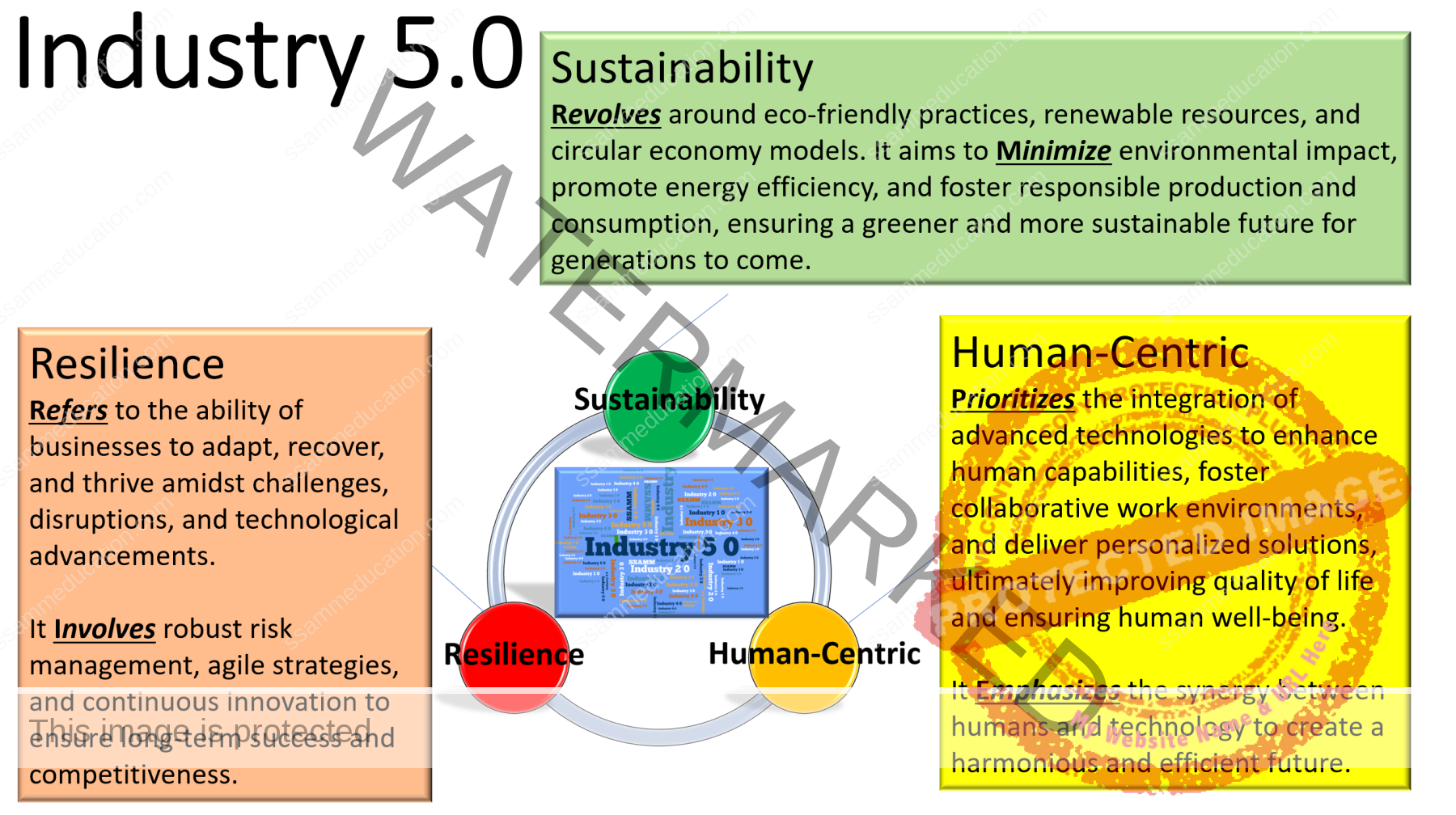

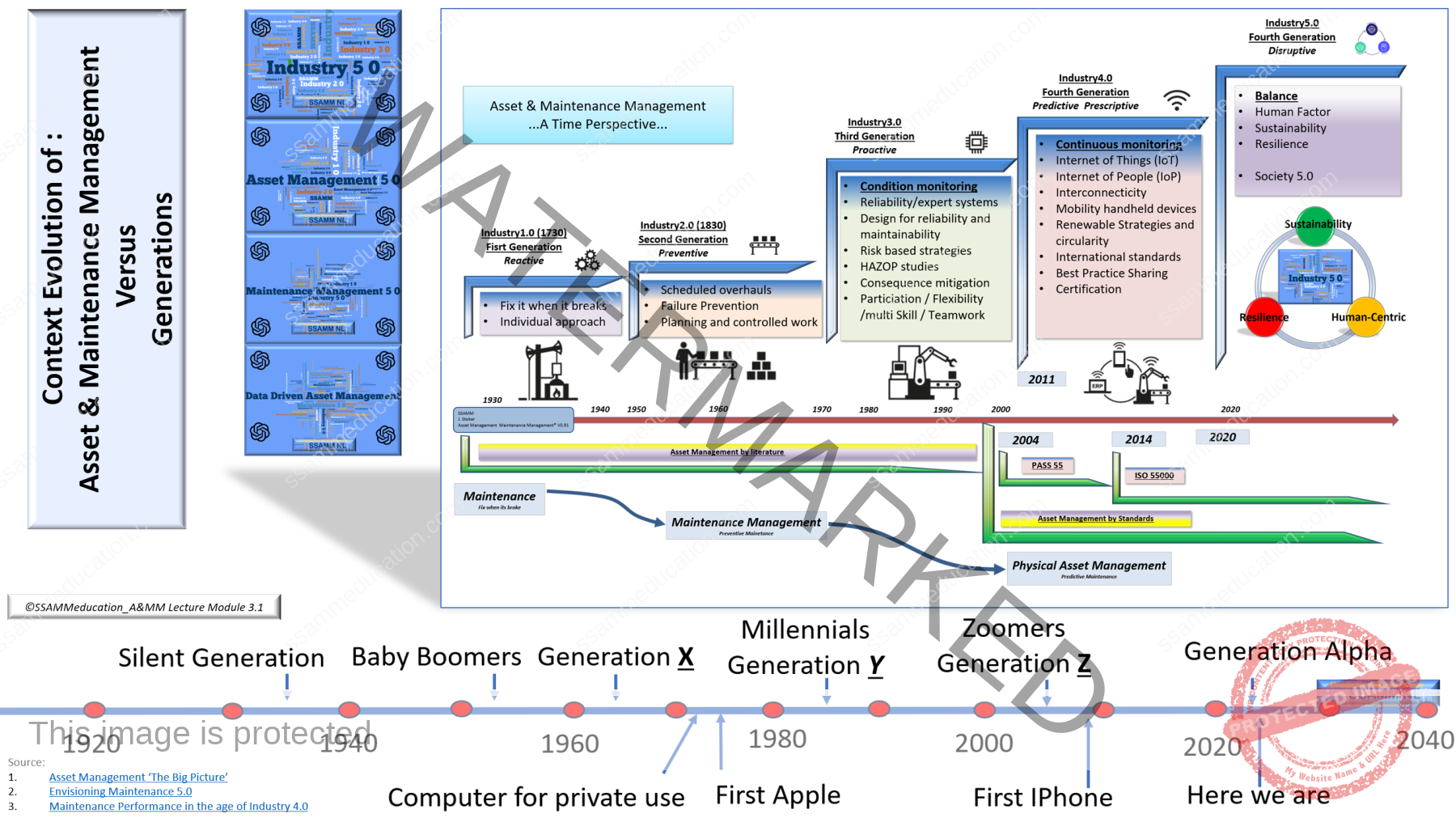

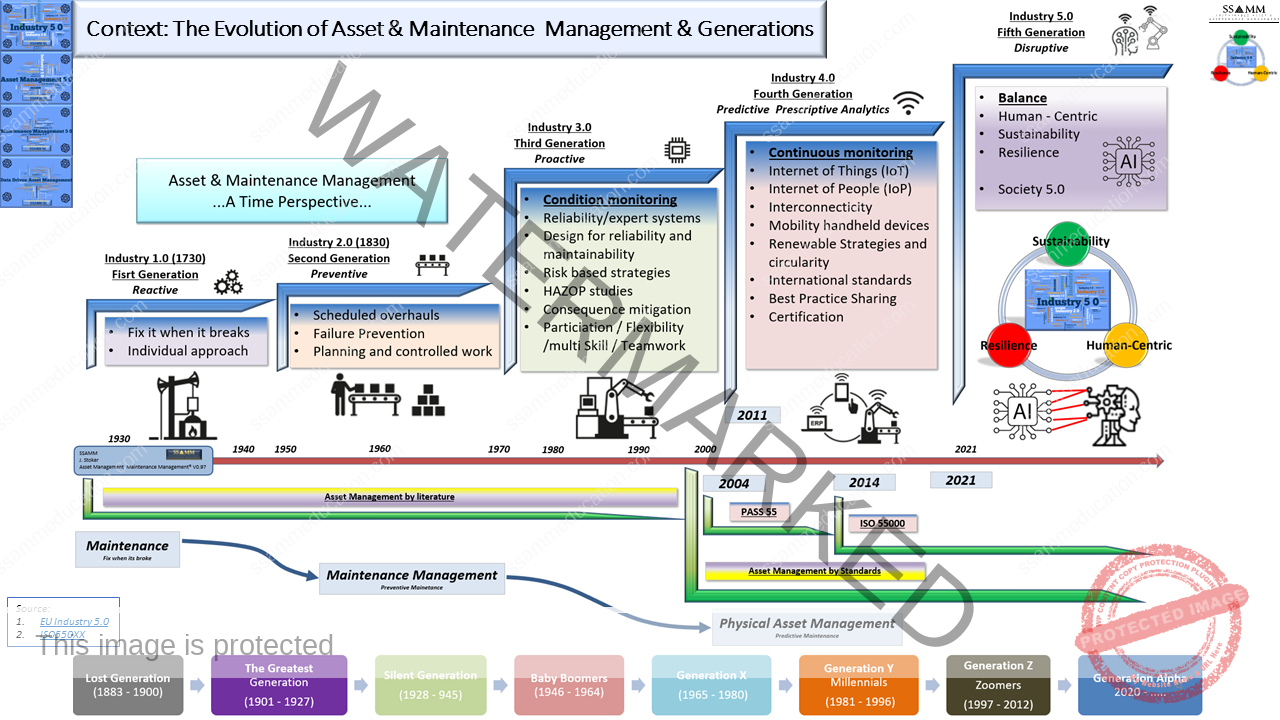

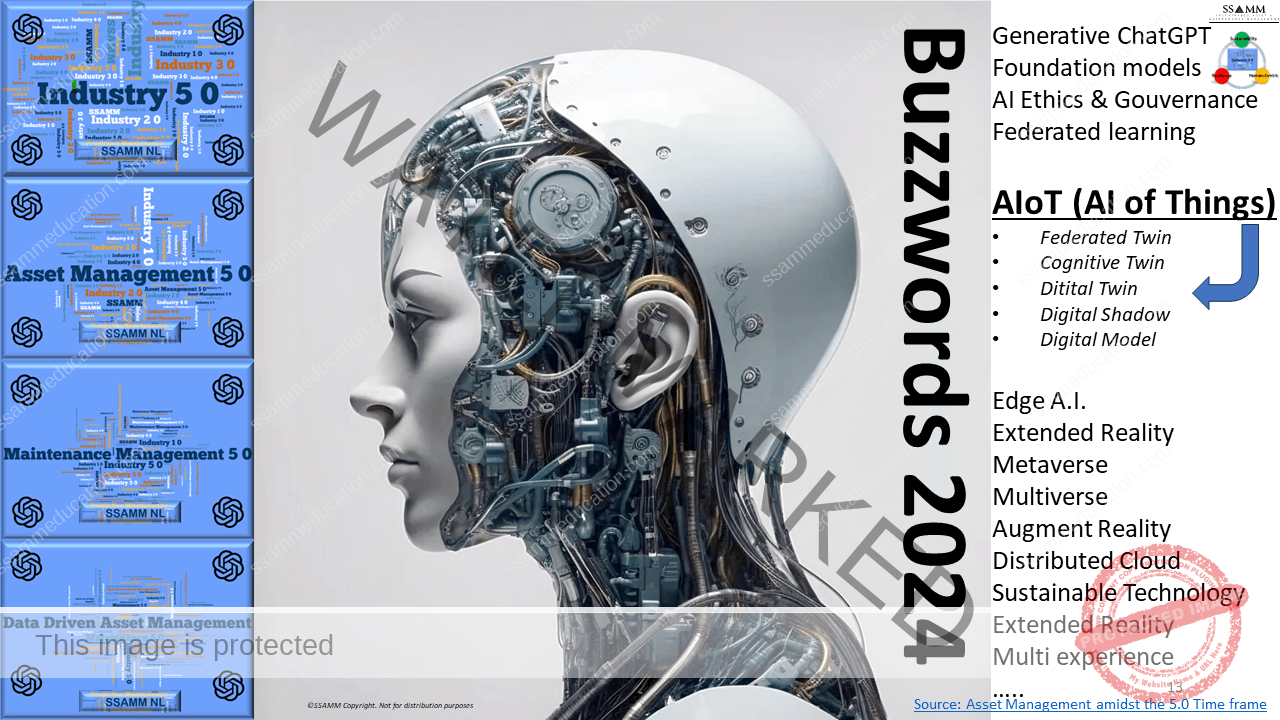

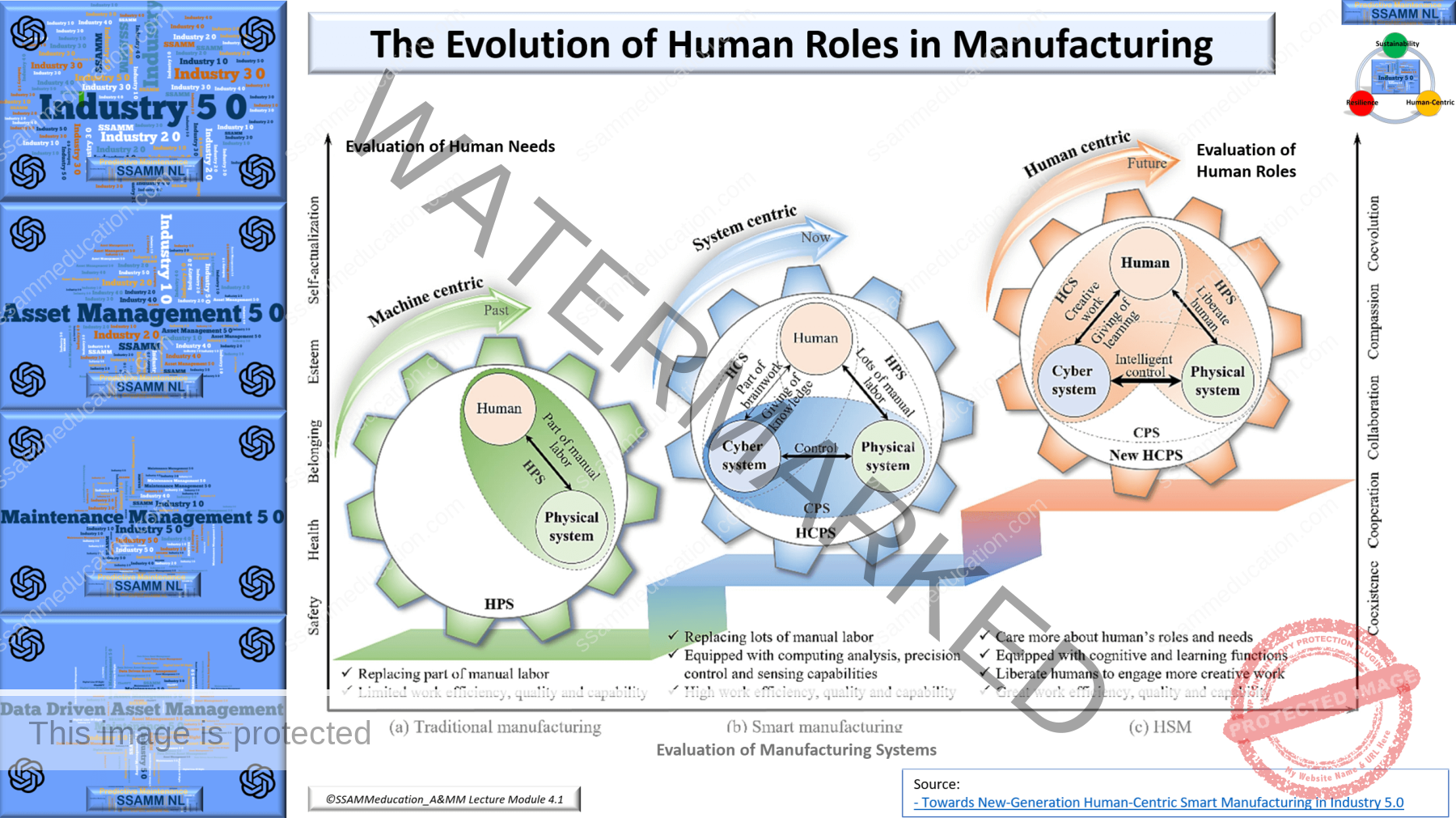

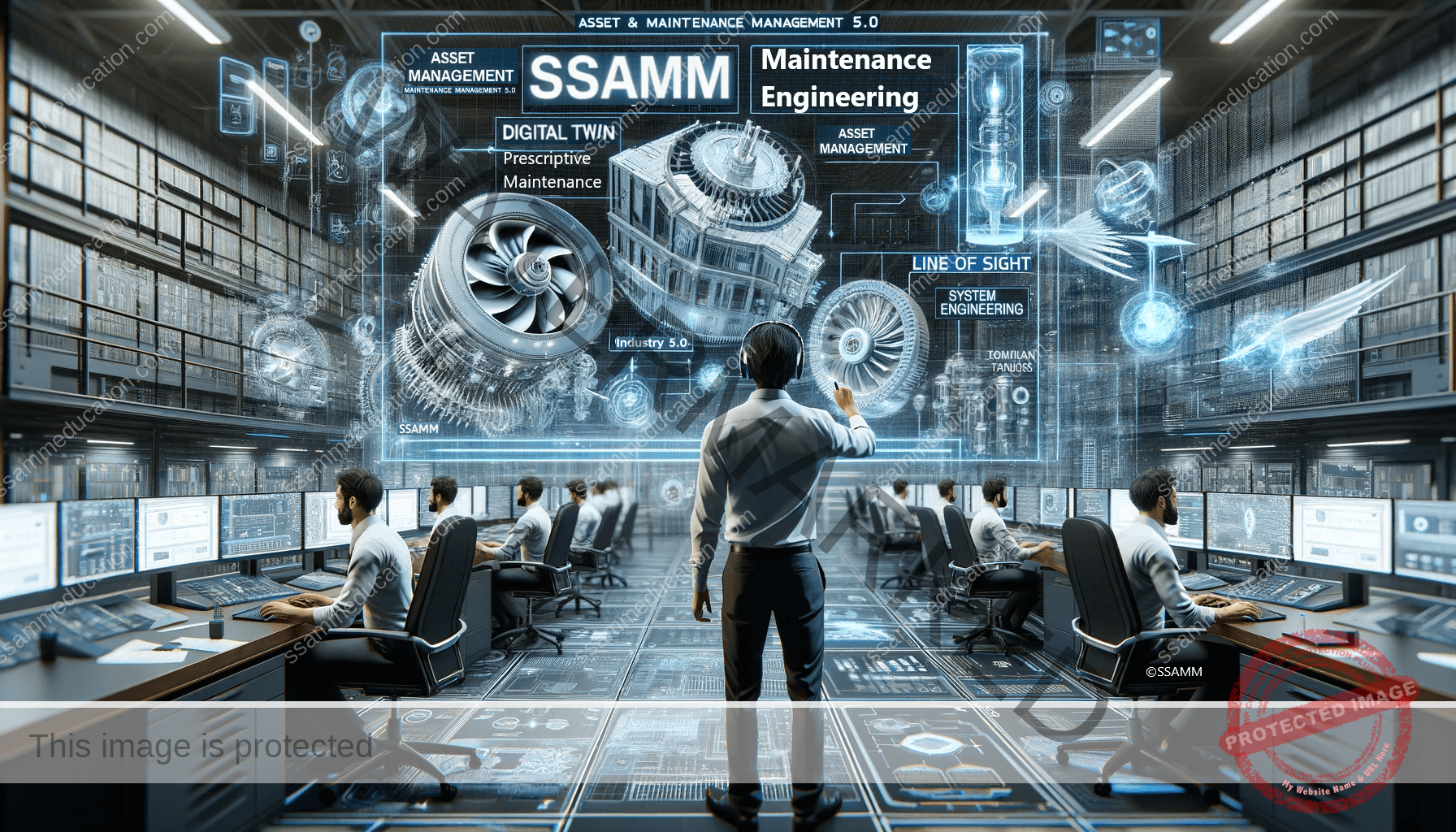

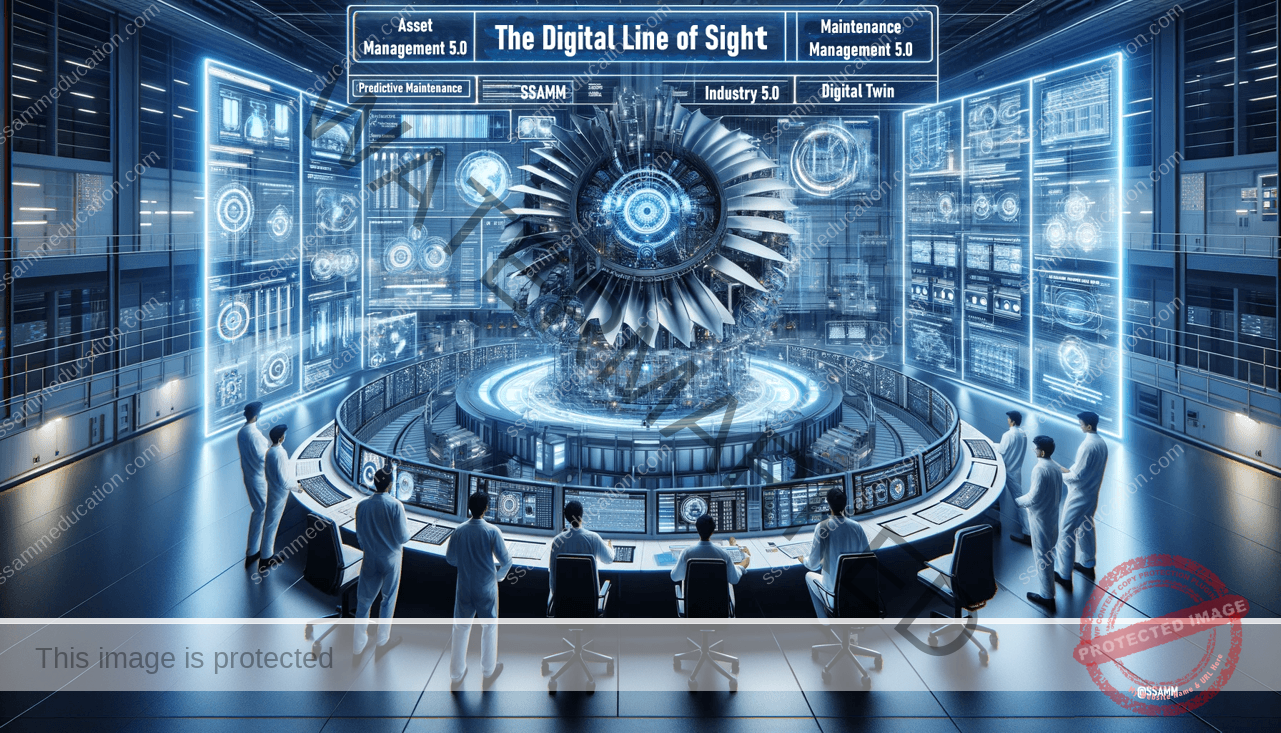

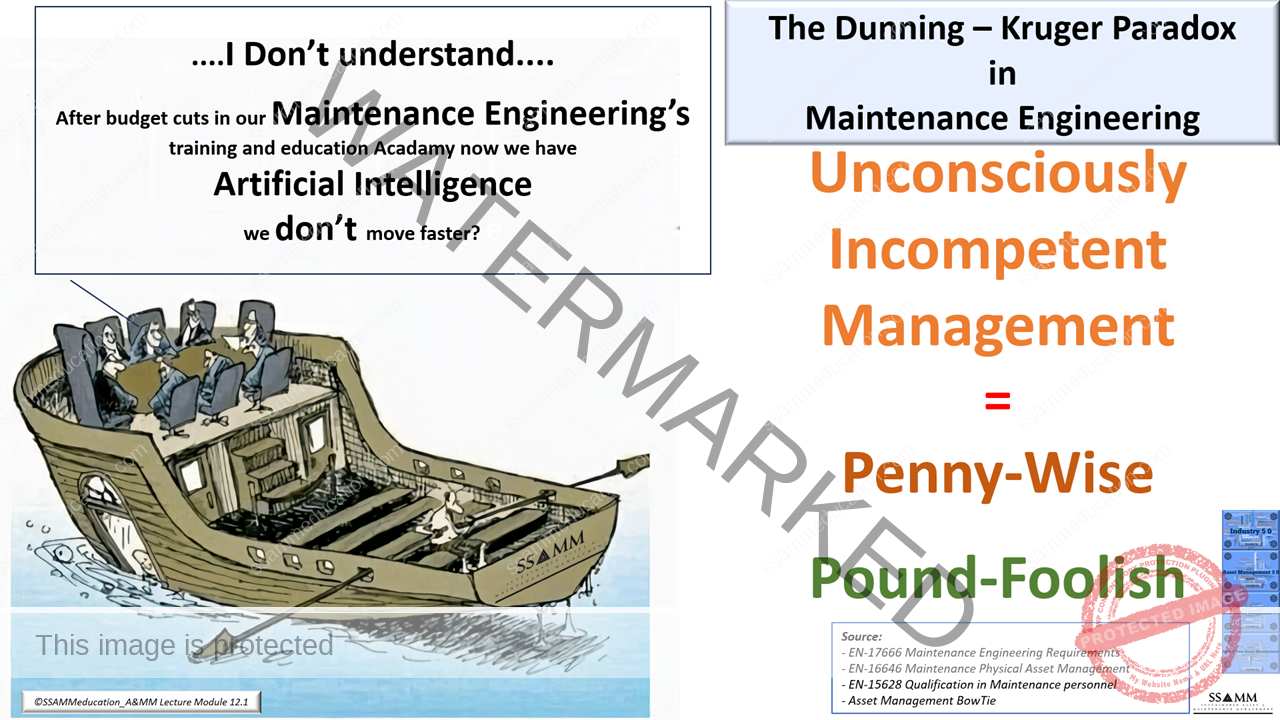

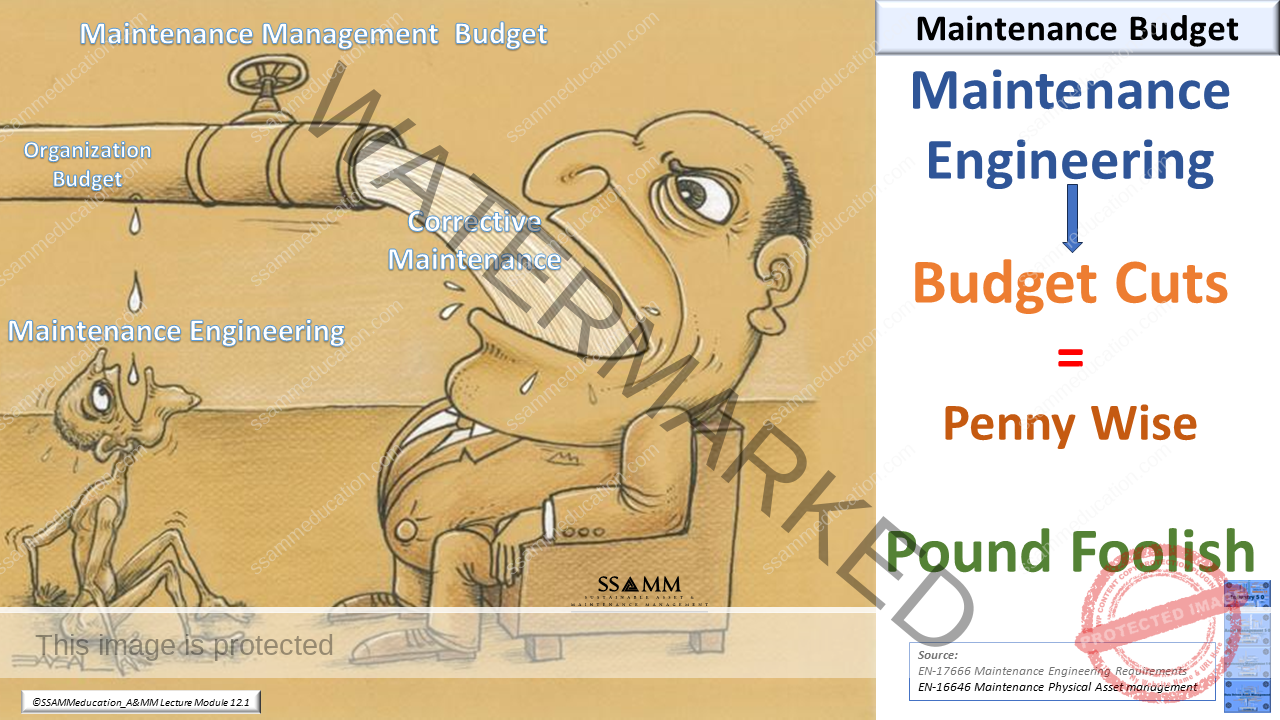

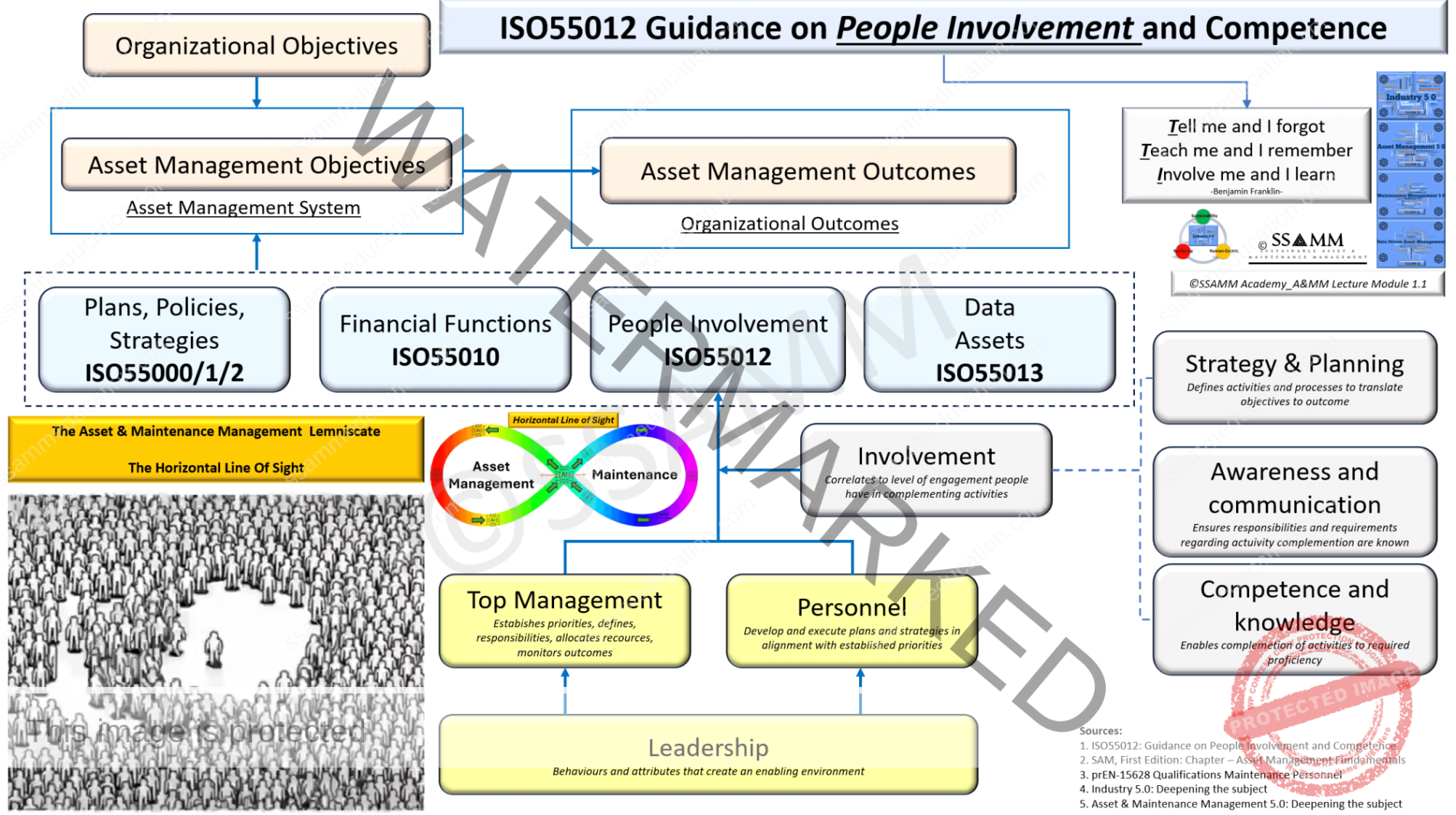

Human-centric amidst the Industry 5.0 Timeframe

Click to enlarge

Reference and Sources. Check below on this Page.

Click Here for all Articles and pages

Click to enlarge

Click to enlarge

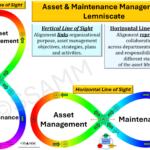

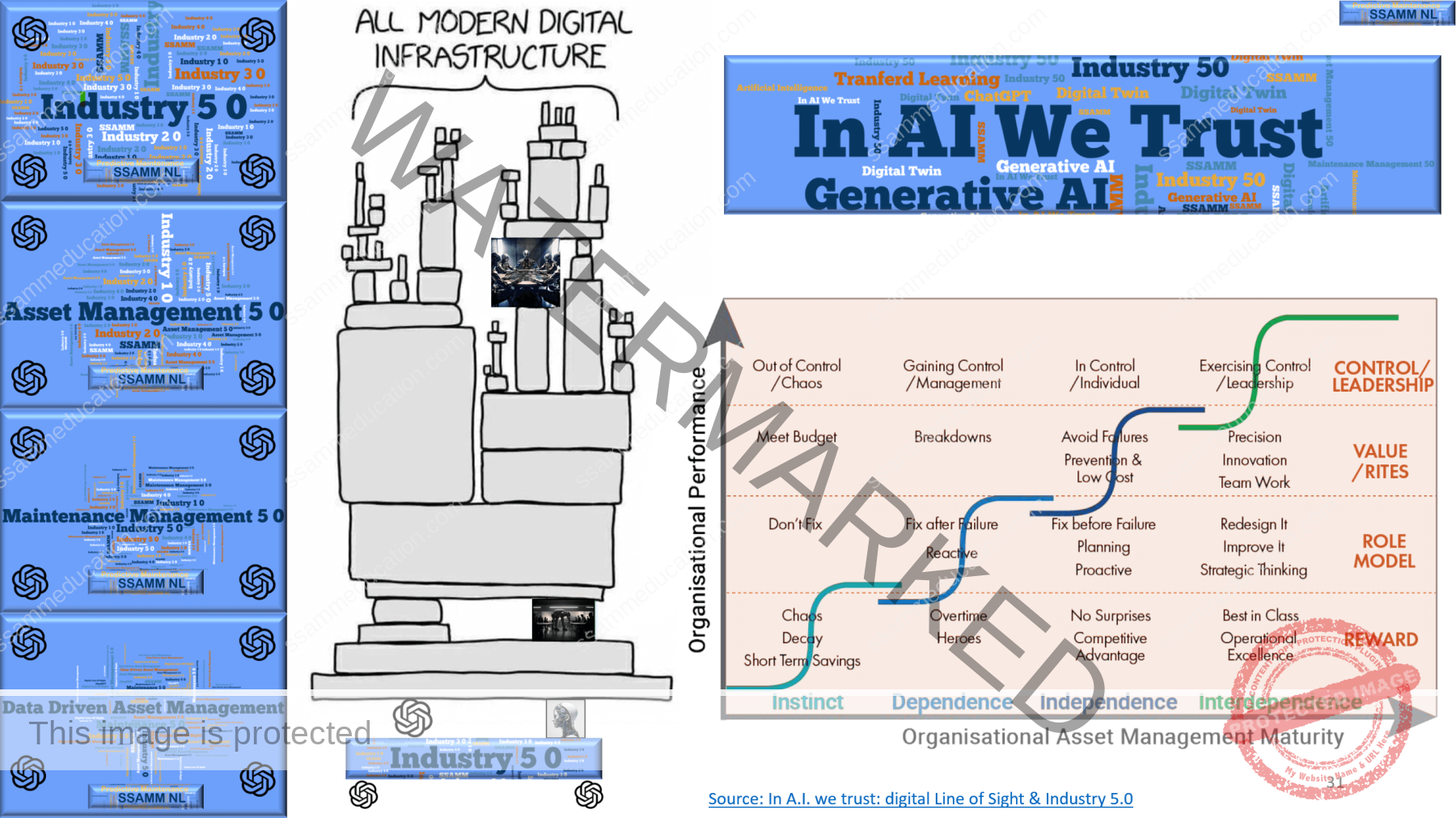

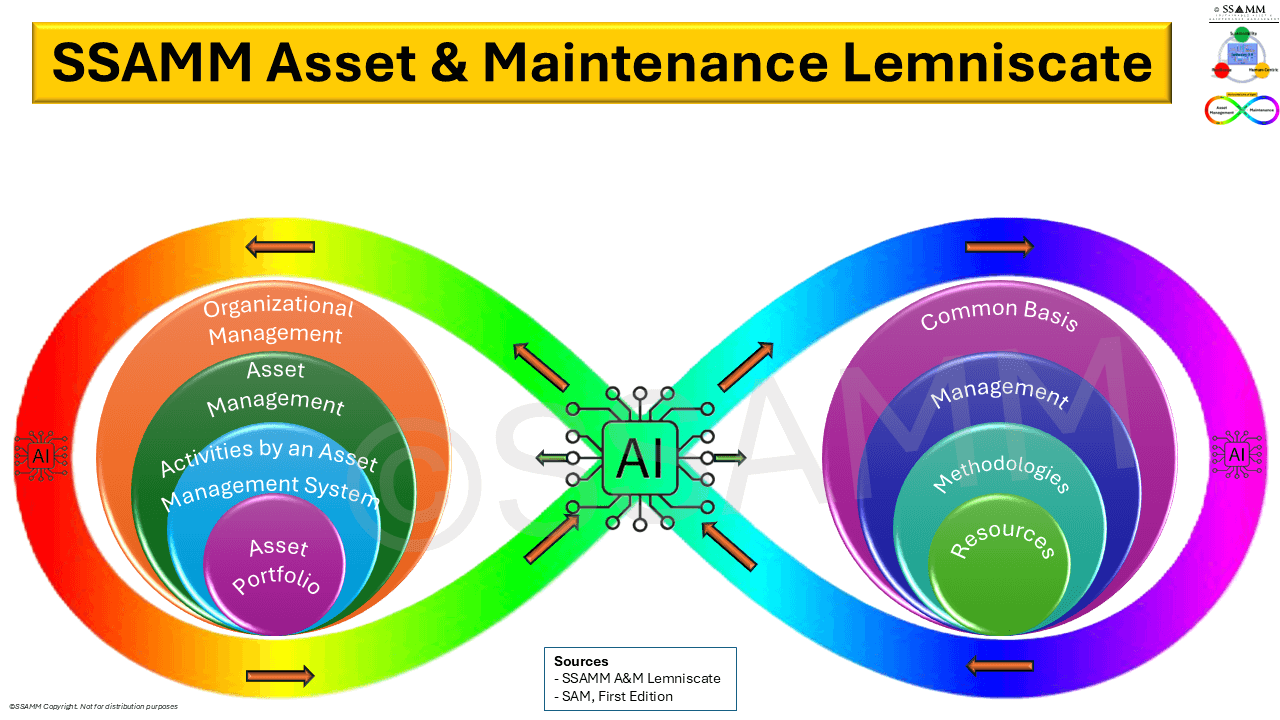

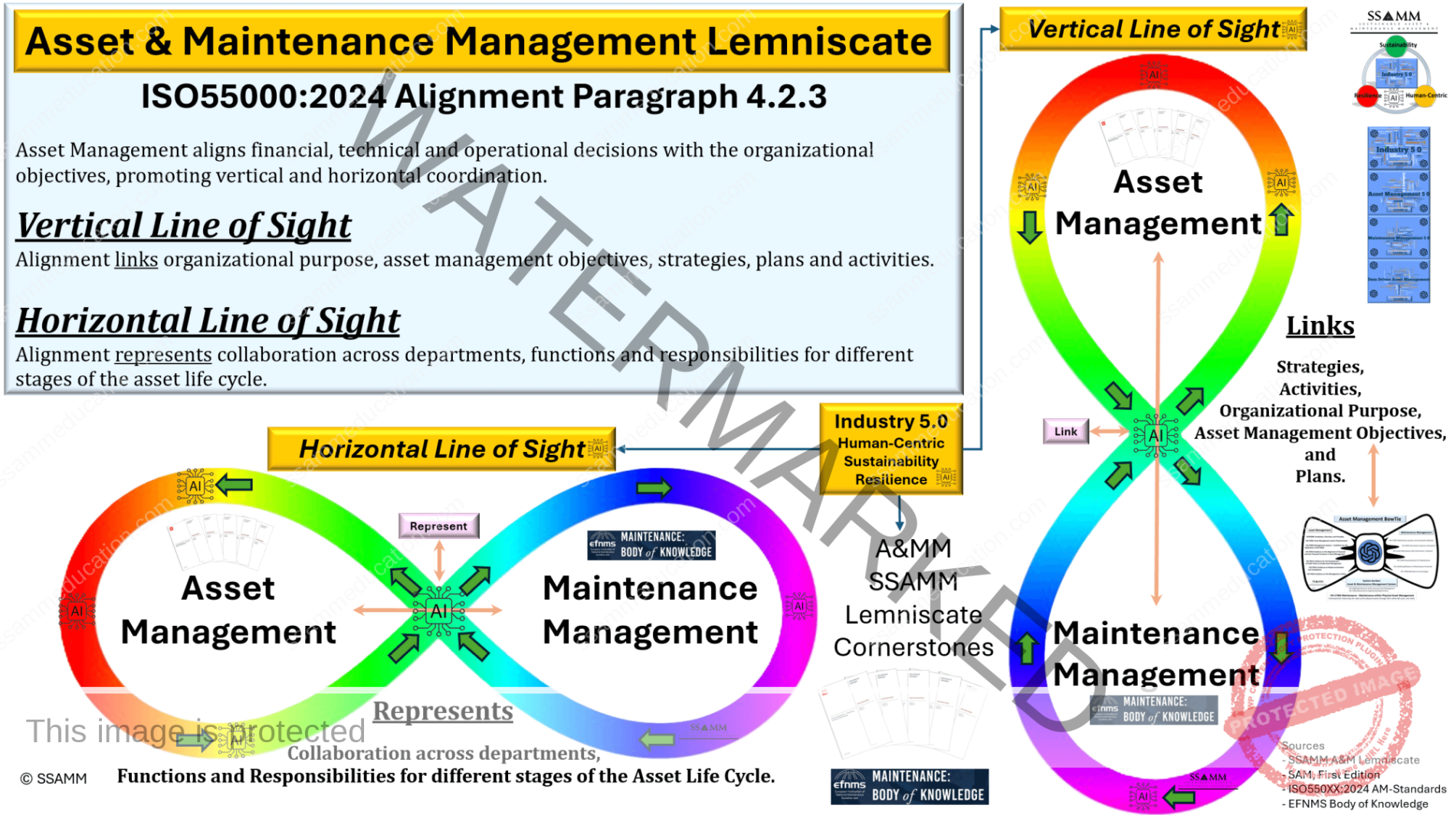

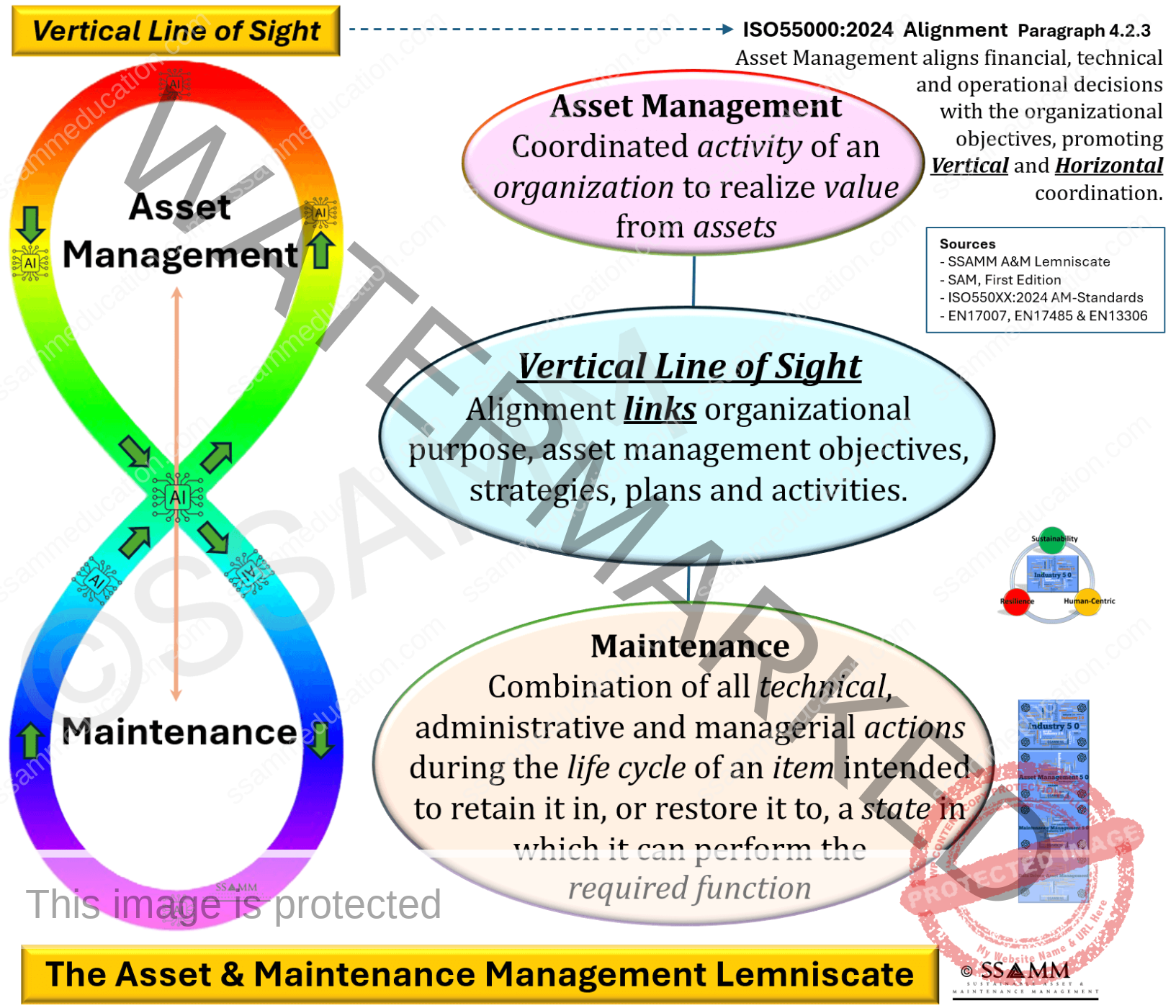

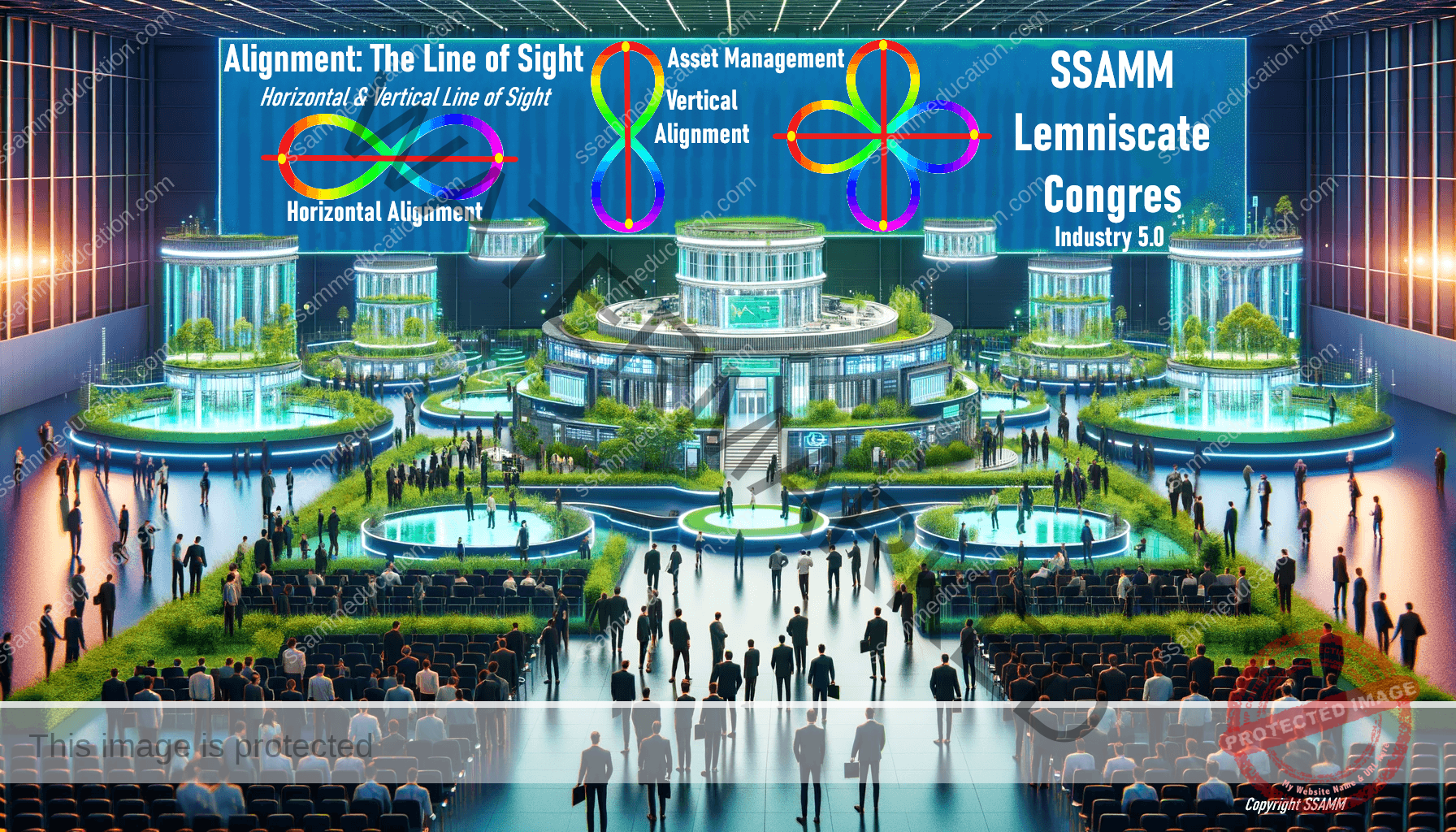

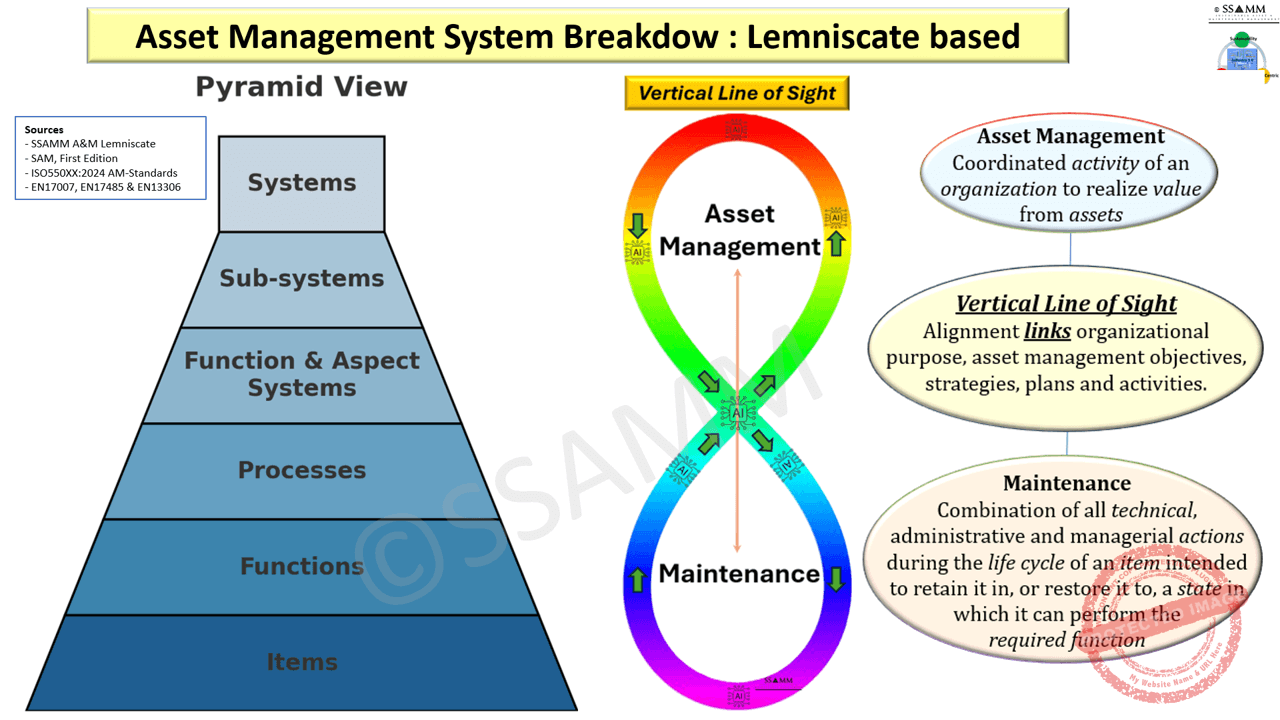

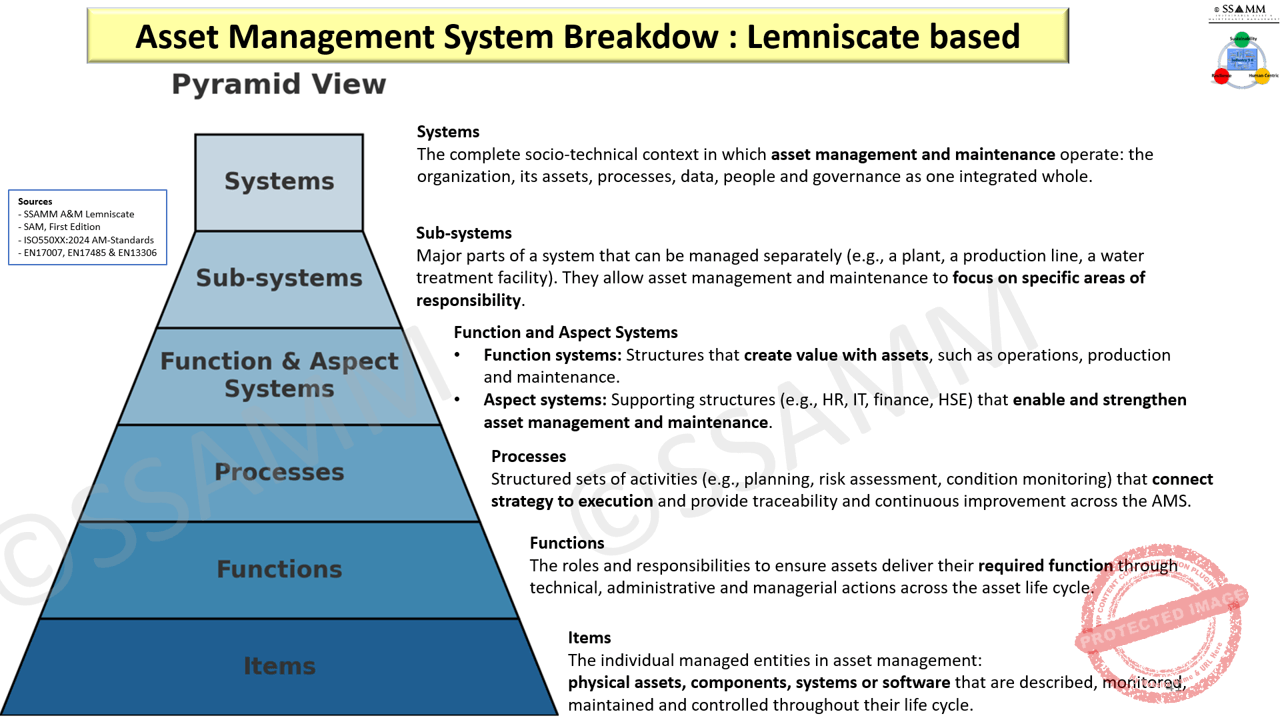

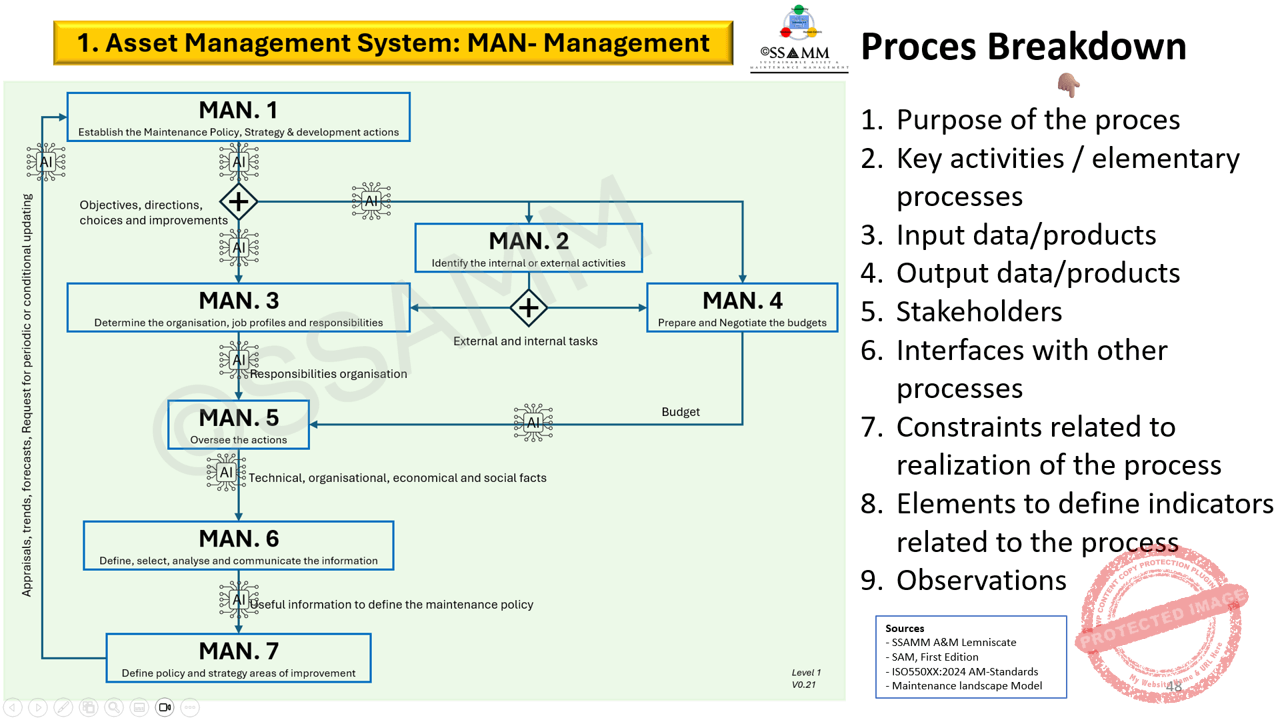

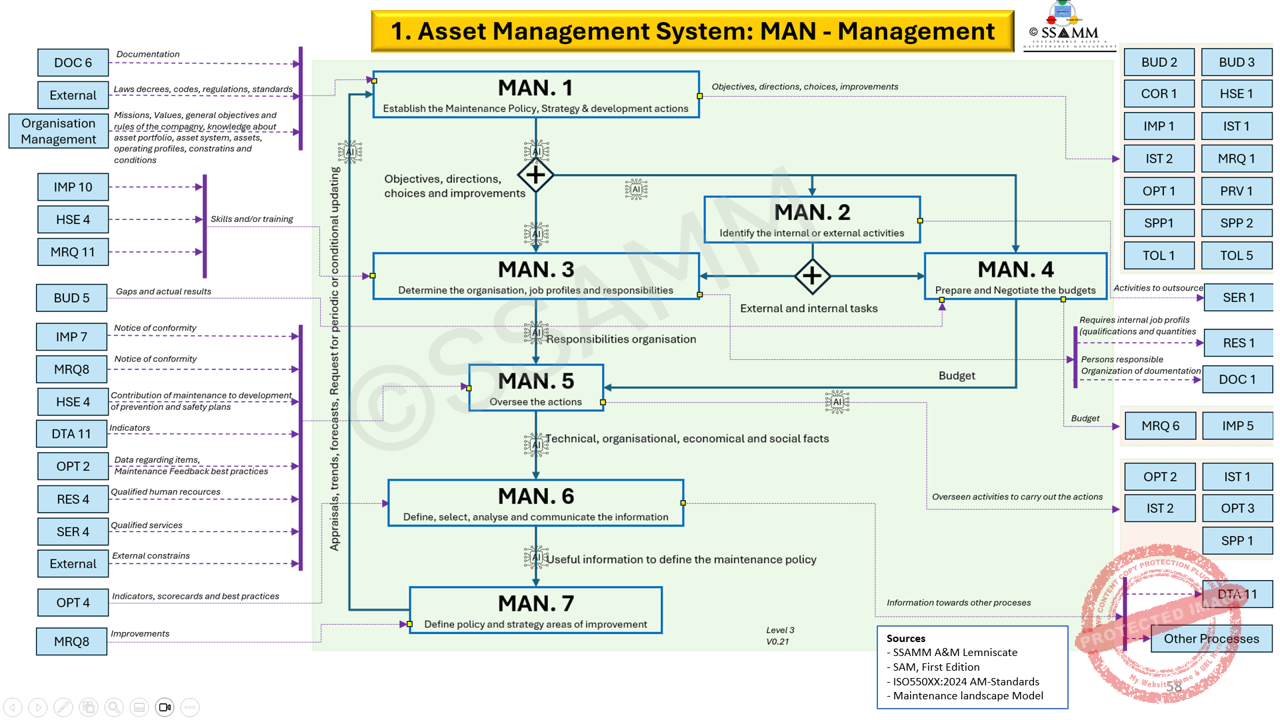

The Asset & Maintenance Management Lemniscate Landscape Models

Click to enlarge

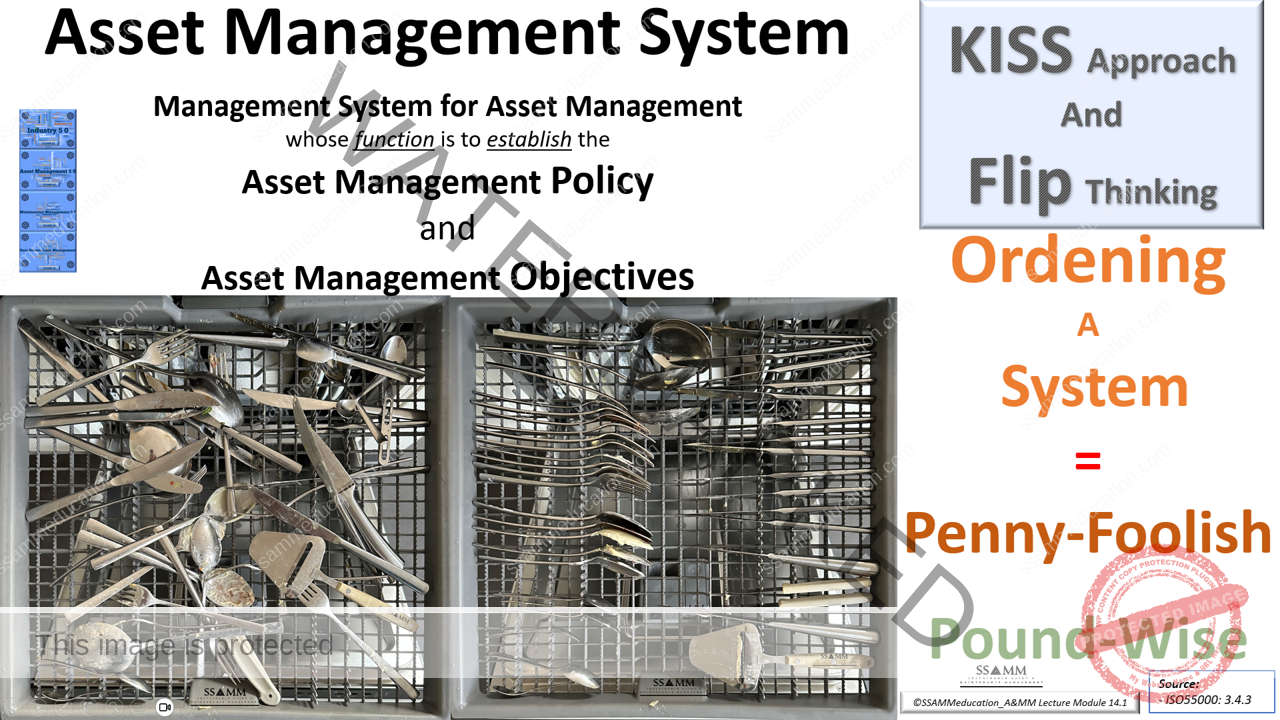

Strategic Asset Management Process Lemniscate: Bridging SAMP and Maintenance Execution

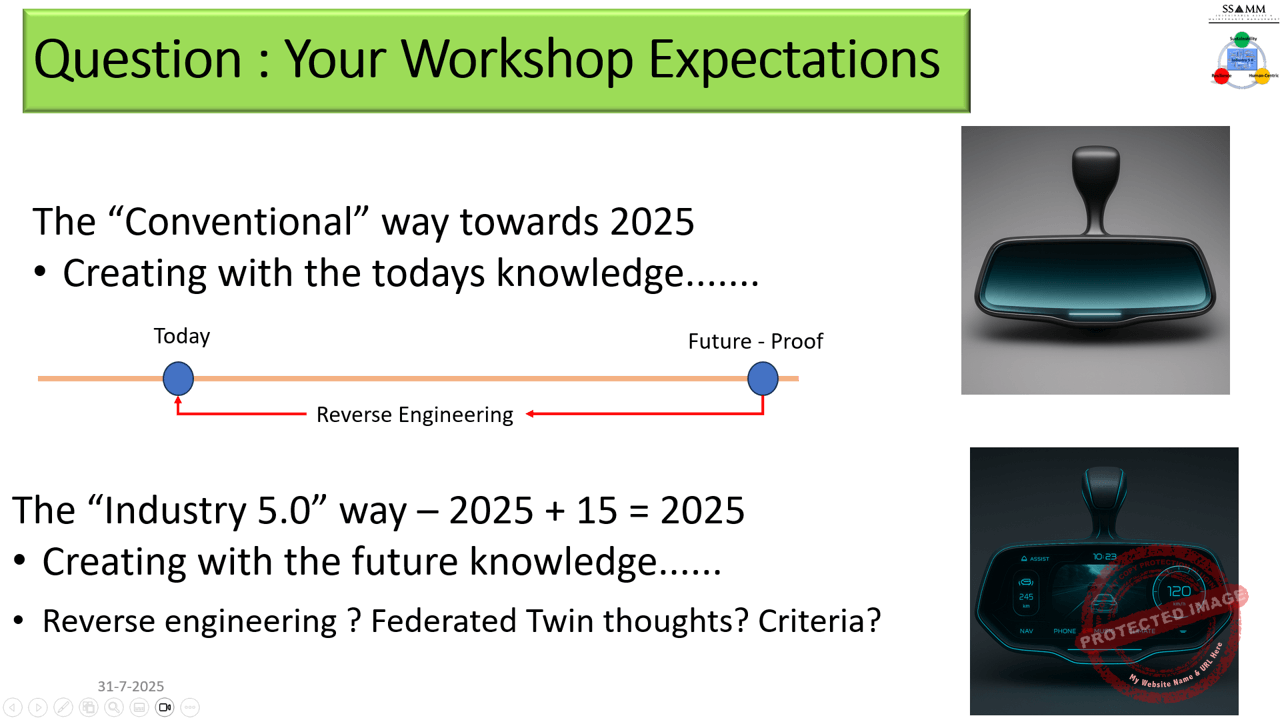

Workshop ‘Building a Futureproof Asset Management System’

Click to enlarge

Click to enlarge

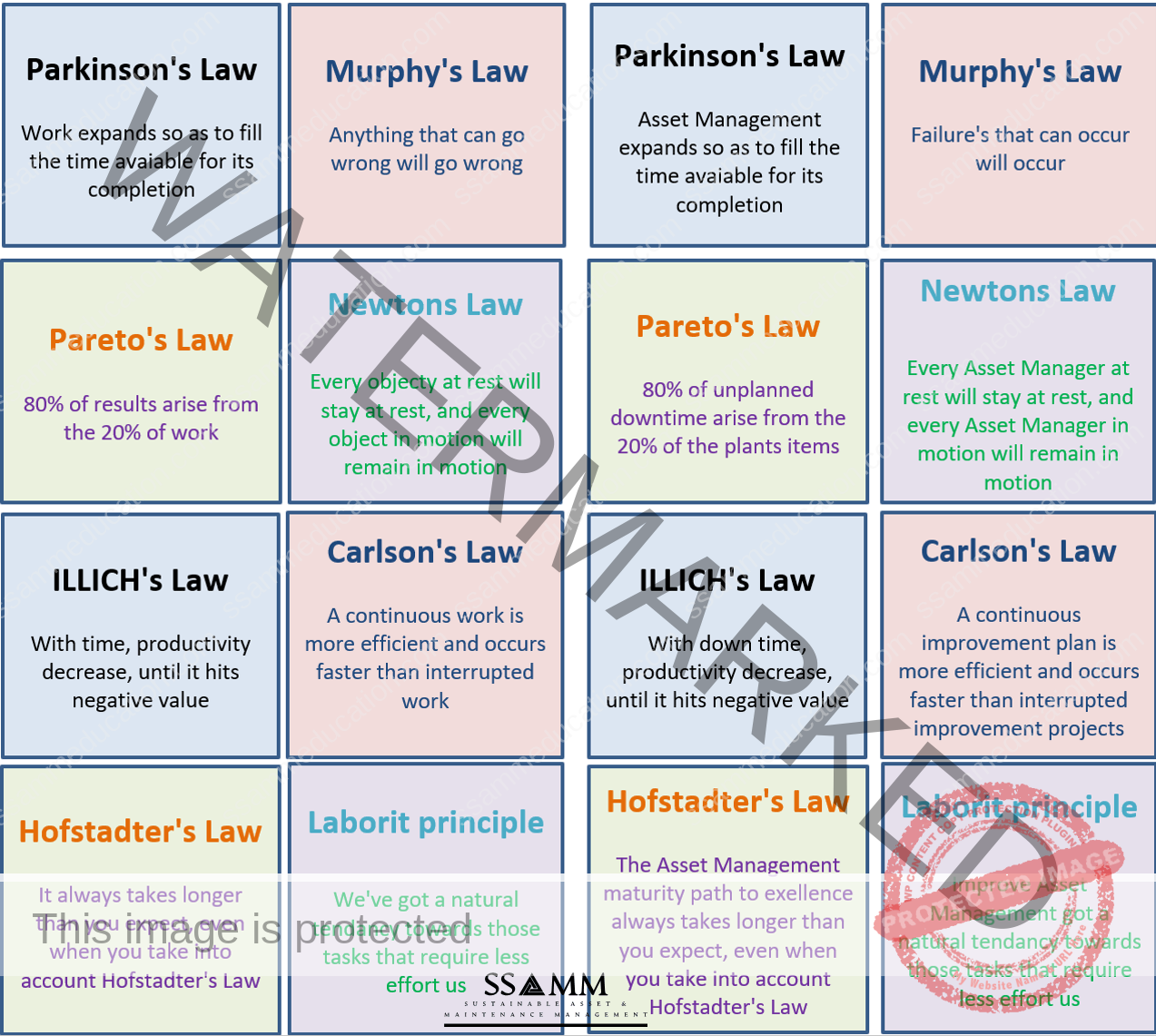

Asset Management Laws & Lyrics with a twist…….

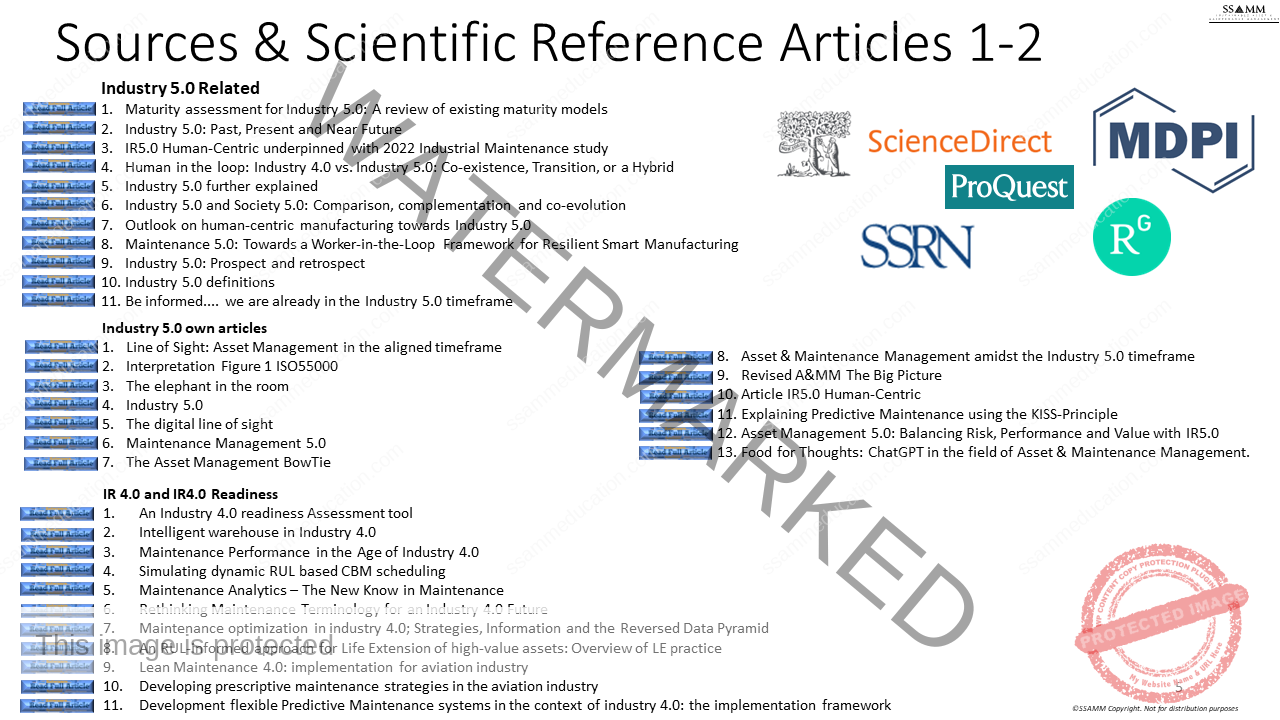

Reference Articles

Industry 5.0 Related

- Maturity assessment for Industry 5.0: A review of existing maturity models

- Industry 5.0: Past, Present and Near Future

- IR5.0 Human-Centric underpinned with 2022 Industrial Maintenance study

- Human in the loop: Industry 4.0 vs. Industry 5.0: Co-existence, Transition, or a Hybrid

- Industry 5.0 further explained

- Industry 5.0 and Society 5.0: Comparison, complementation and co-evolution

- Outlook on human-centric manufacturing towards Industry 5.0

- Maintenance 5.0: Towards a Worker-in-the-Loop Framework for Resilient Smart Manufacturing

- Industry 5.0: Prospect and retrospect

- Industry 5.0 definitions

- Be informed…. we are already in the Industry 5.0 timeframe

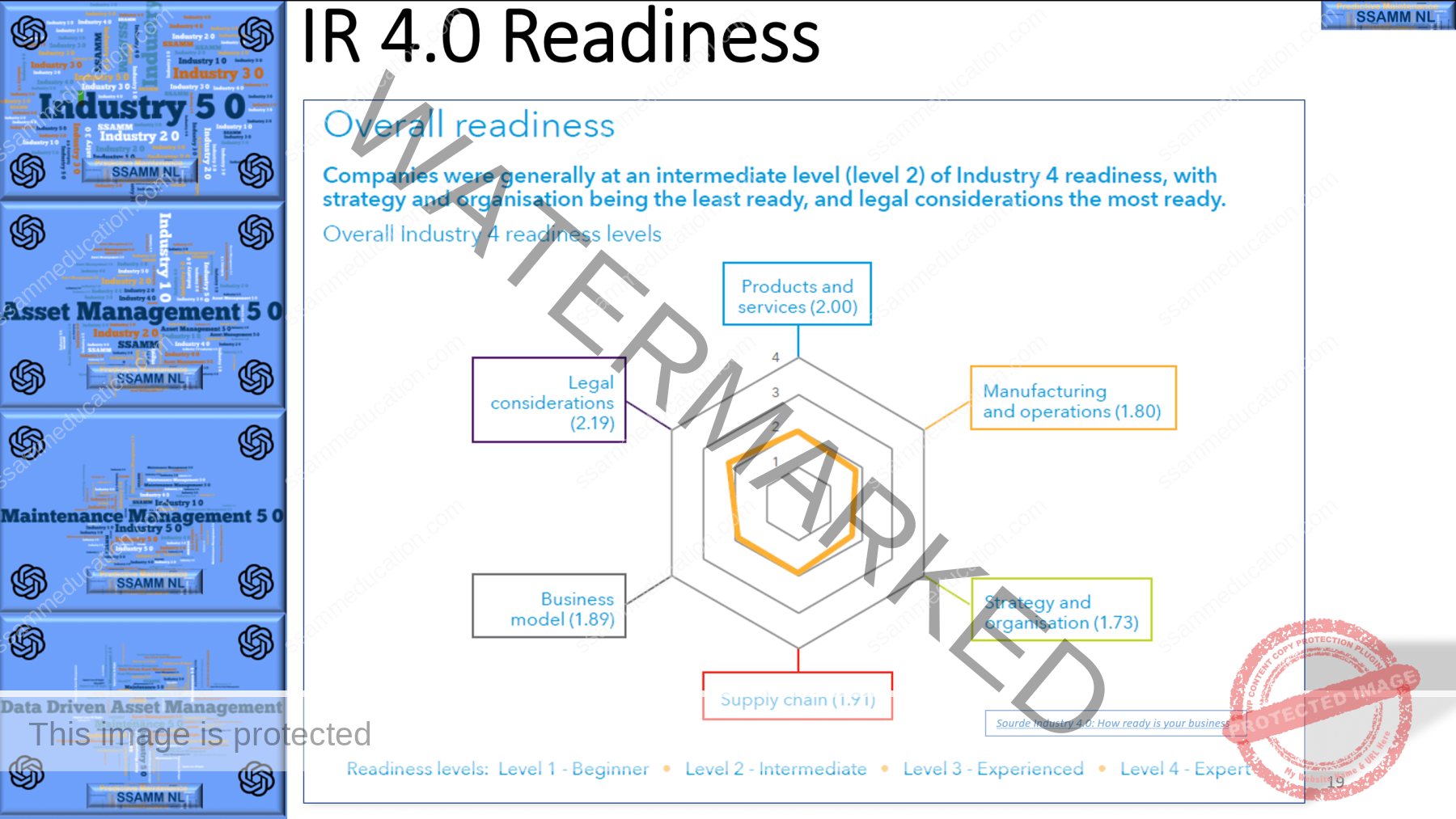

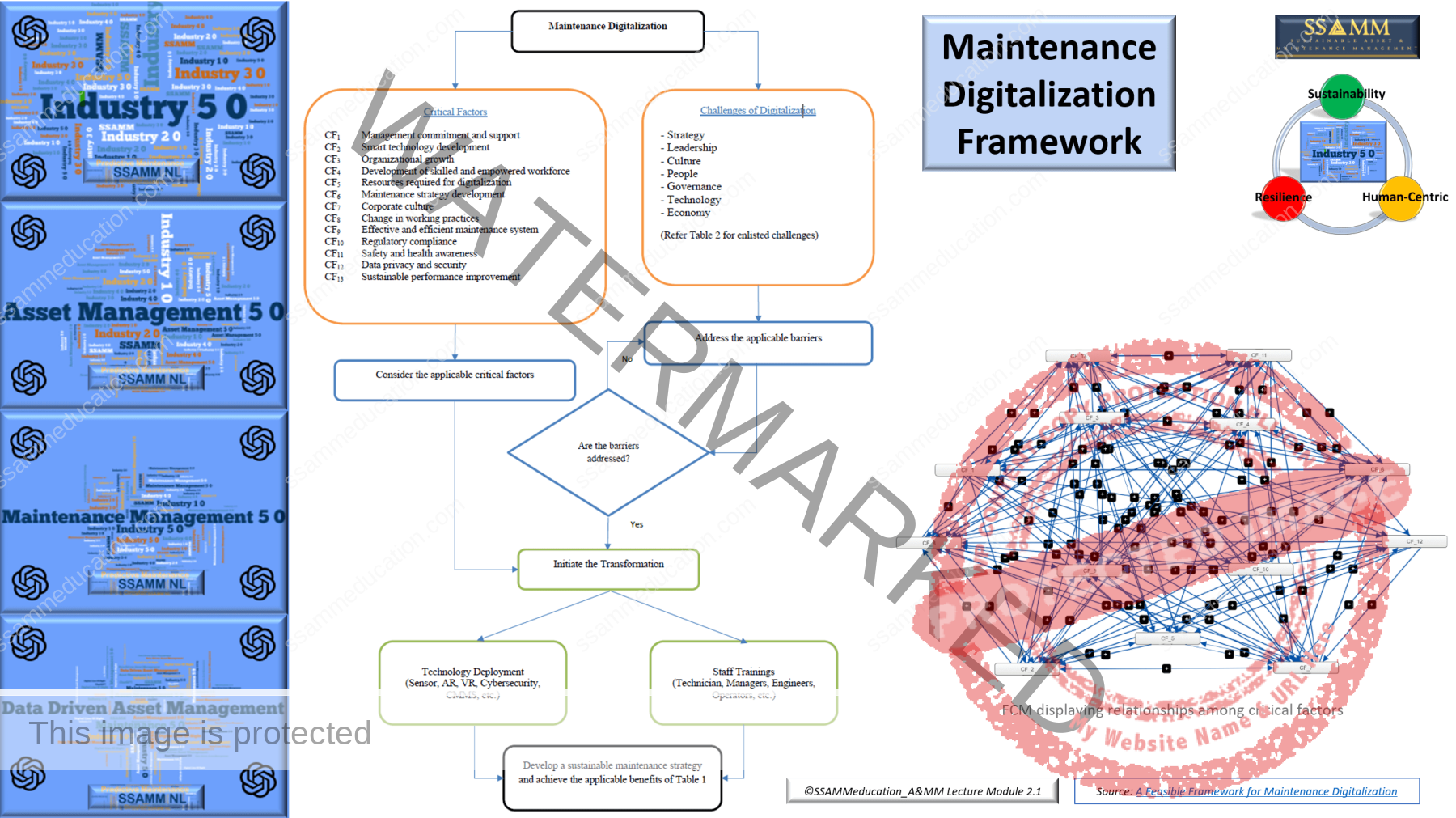

IR4.0 & IR4.0 Readiness

- An Industry 4.0 readiness Assessment tool

- Intelligent warehouse in Industry 4.0

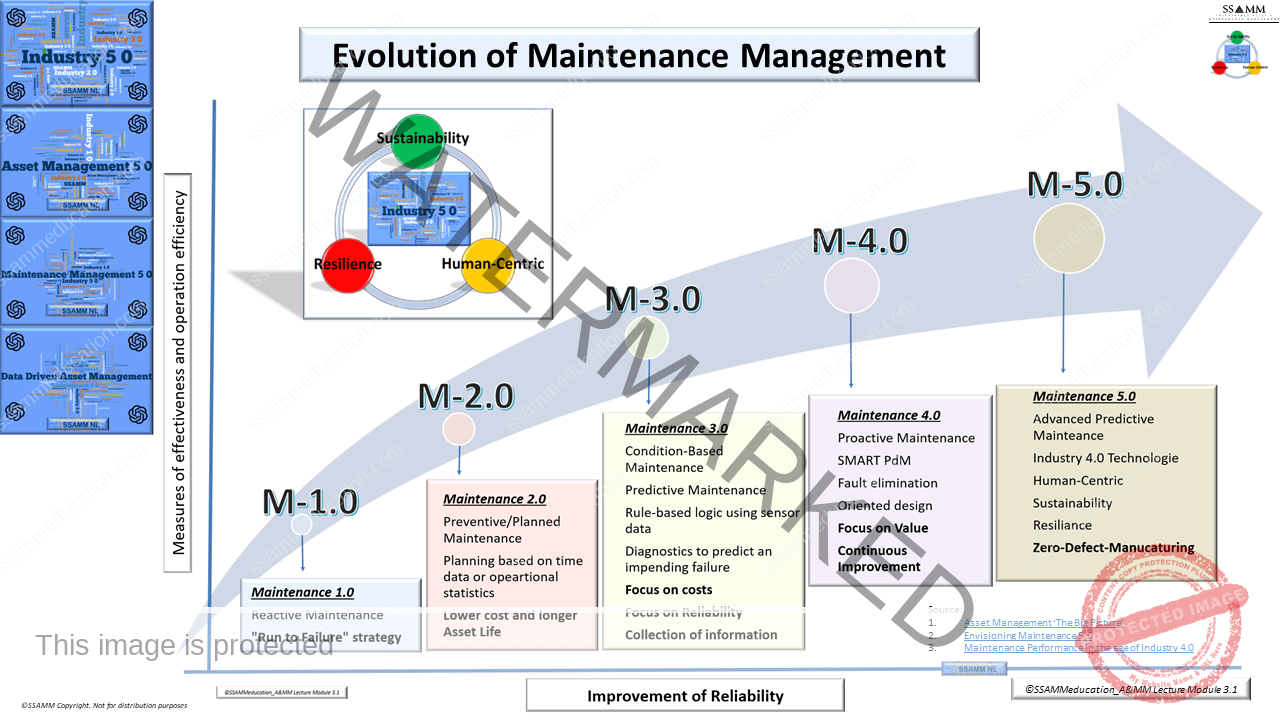

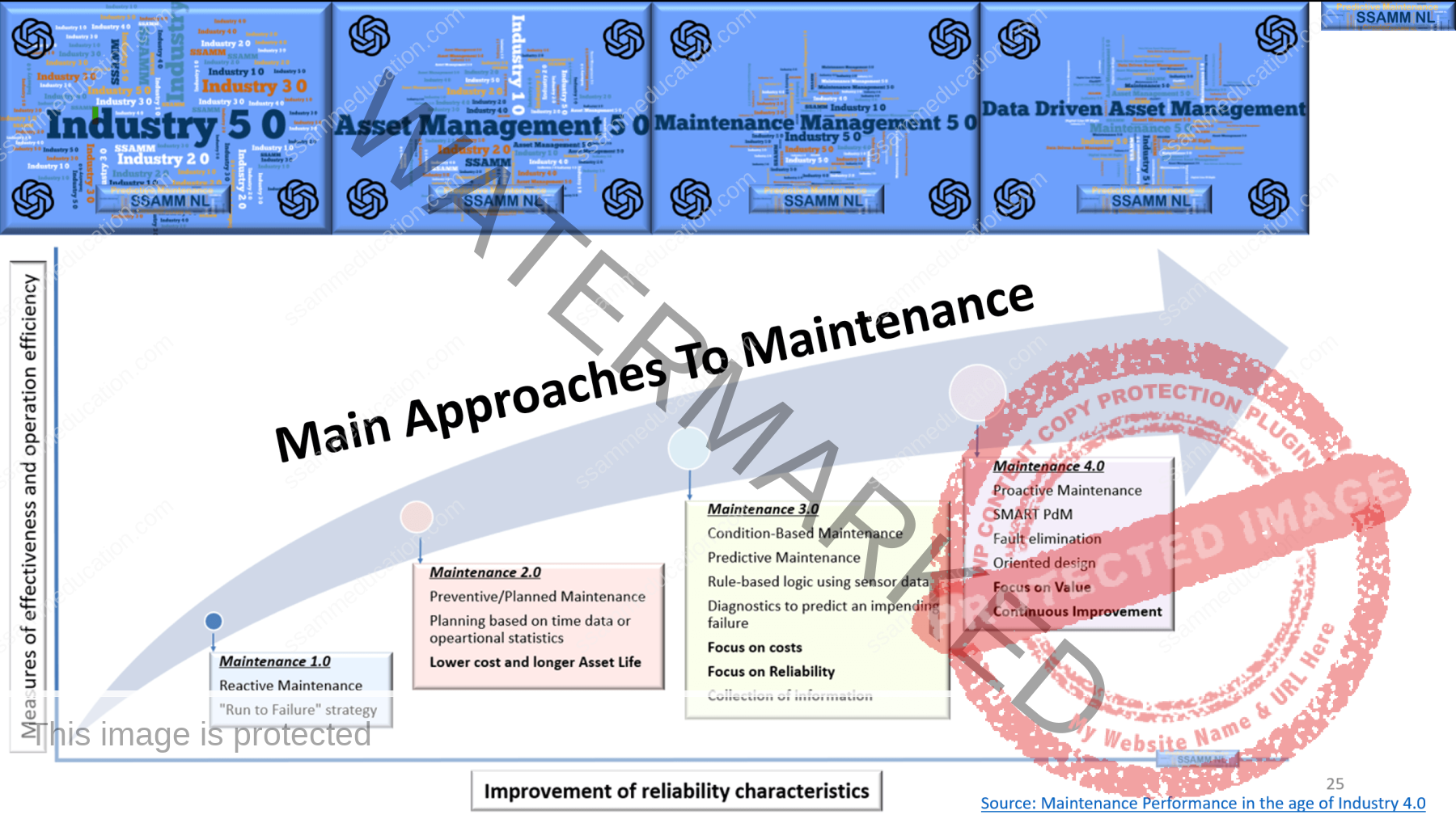

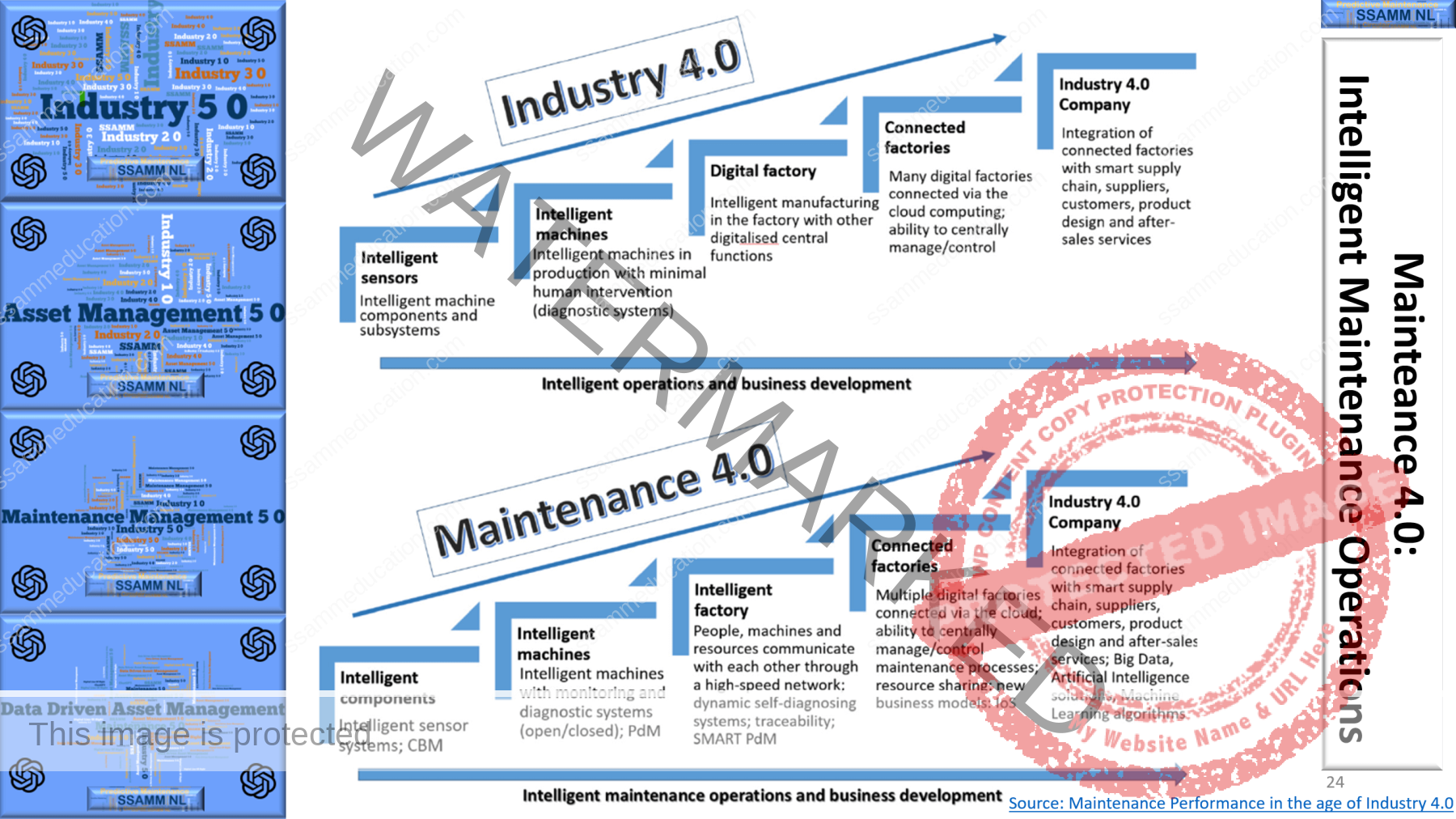

- Maintenance Performance in the Age of Industry 4.0

- Simulating dynamic RUL based CBM scheduling

- Maintenance Analytics – The New Know in Maintenance

- Rethinking Maintenance Terminology for an Industry 4.0 Future

- Maintenance optimization in industry 4.0; Strategies, Information and the Reversed Data Pyramid

- An RUL-informed approach for Life Extension of high-value assets: Overview of LE practice

- Lean Maintenance 4.0: implementation for aviation industry

- Developing prescriptive maintenance strategies in the aviation industry

- Development of flexible Predictive Maintenance systems in the context of industry 4.0: the implementation framework

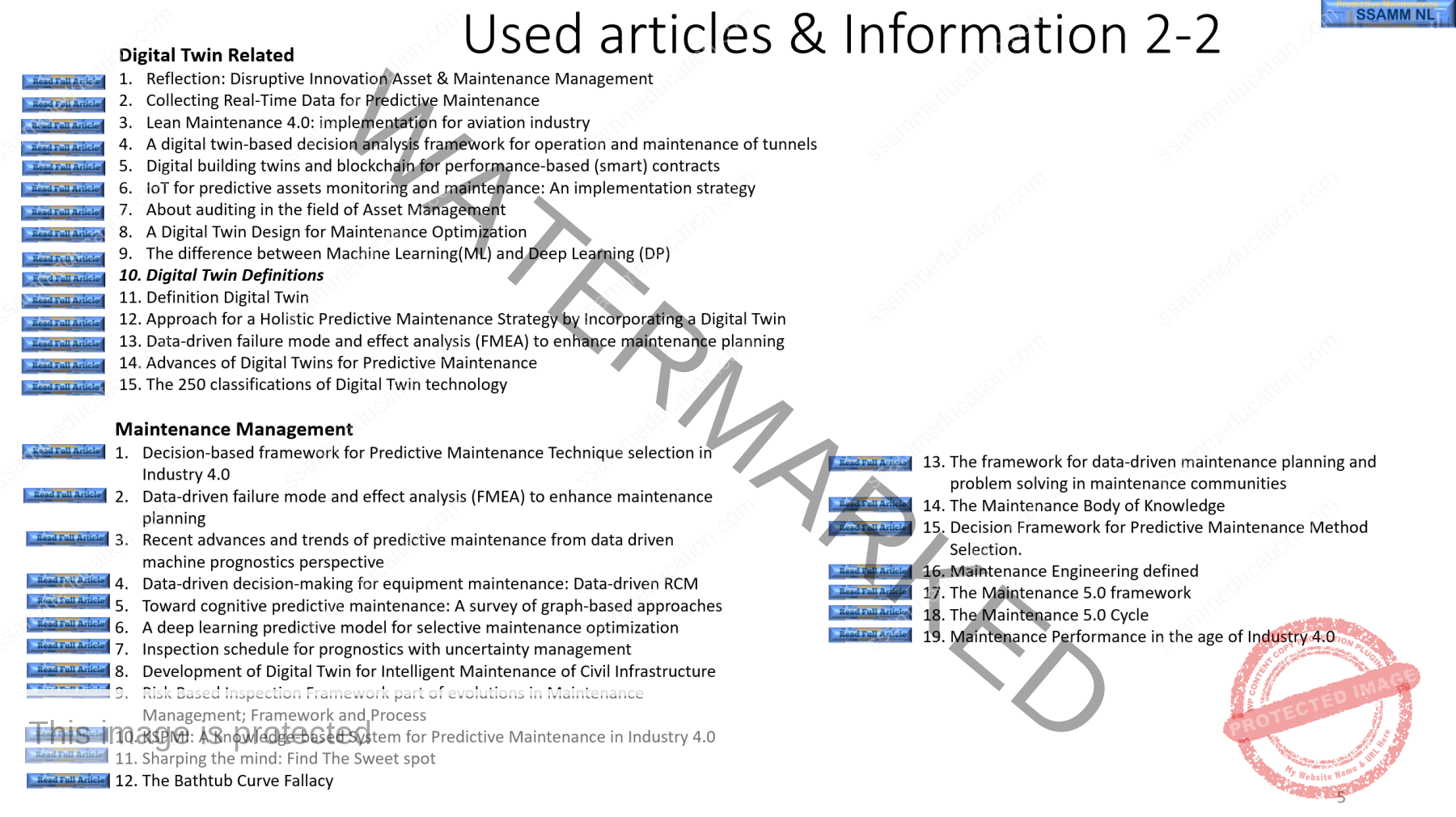

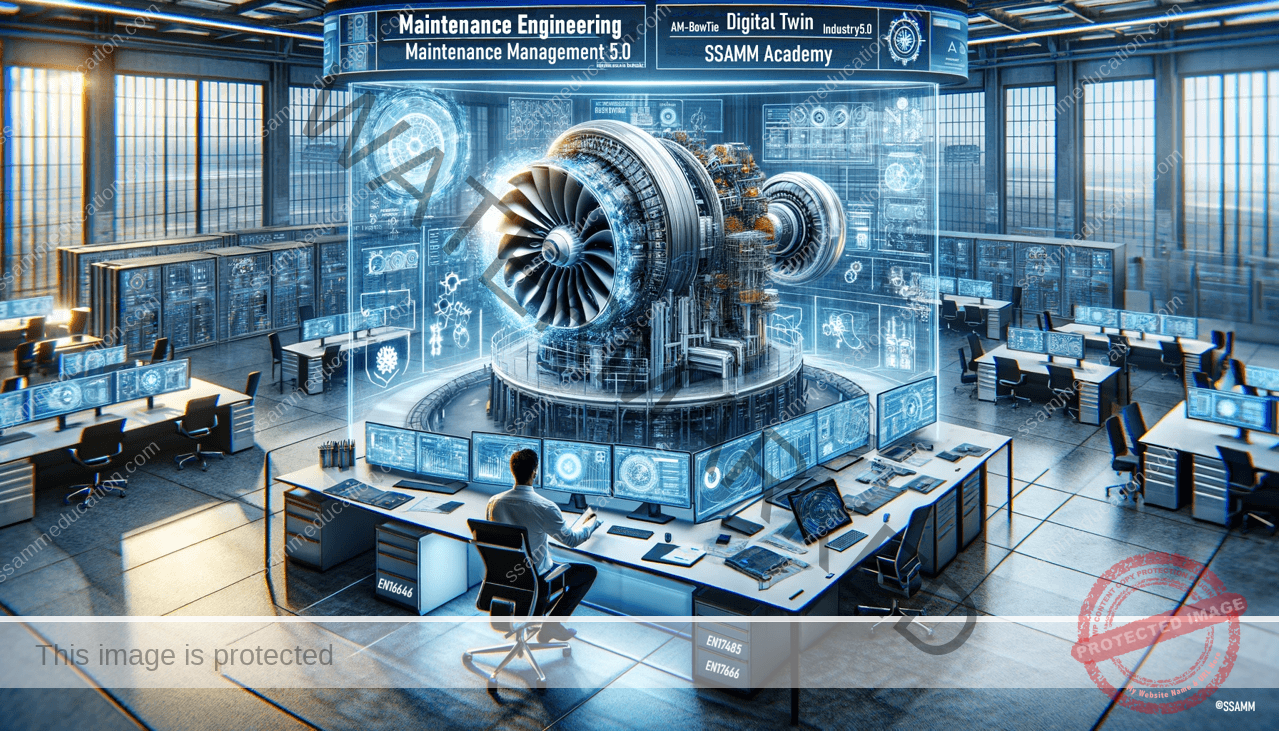

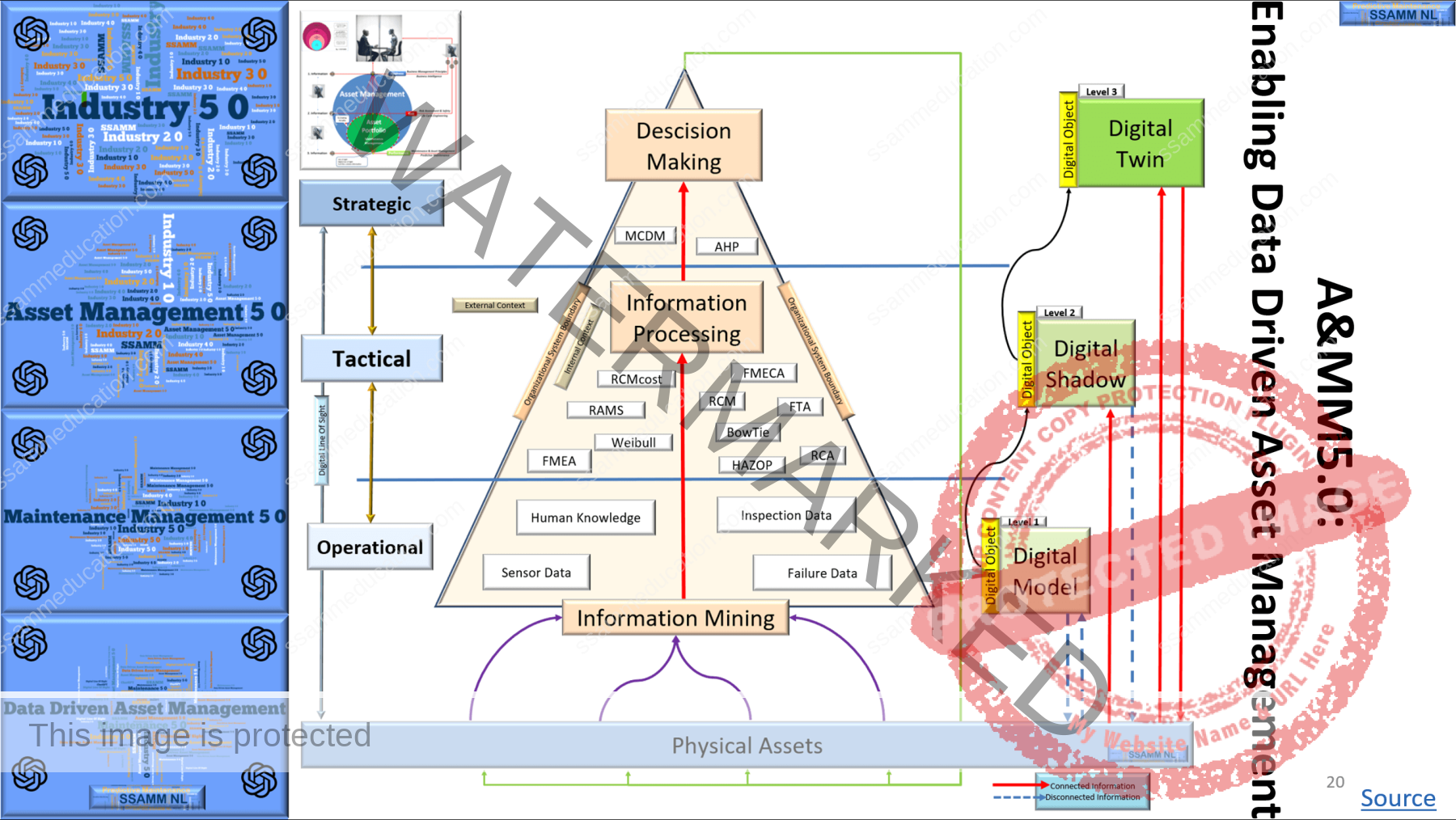

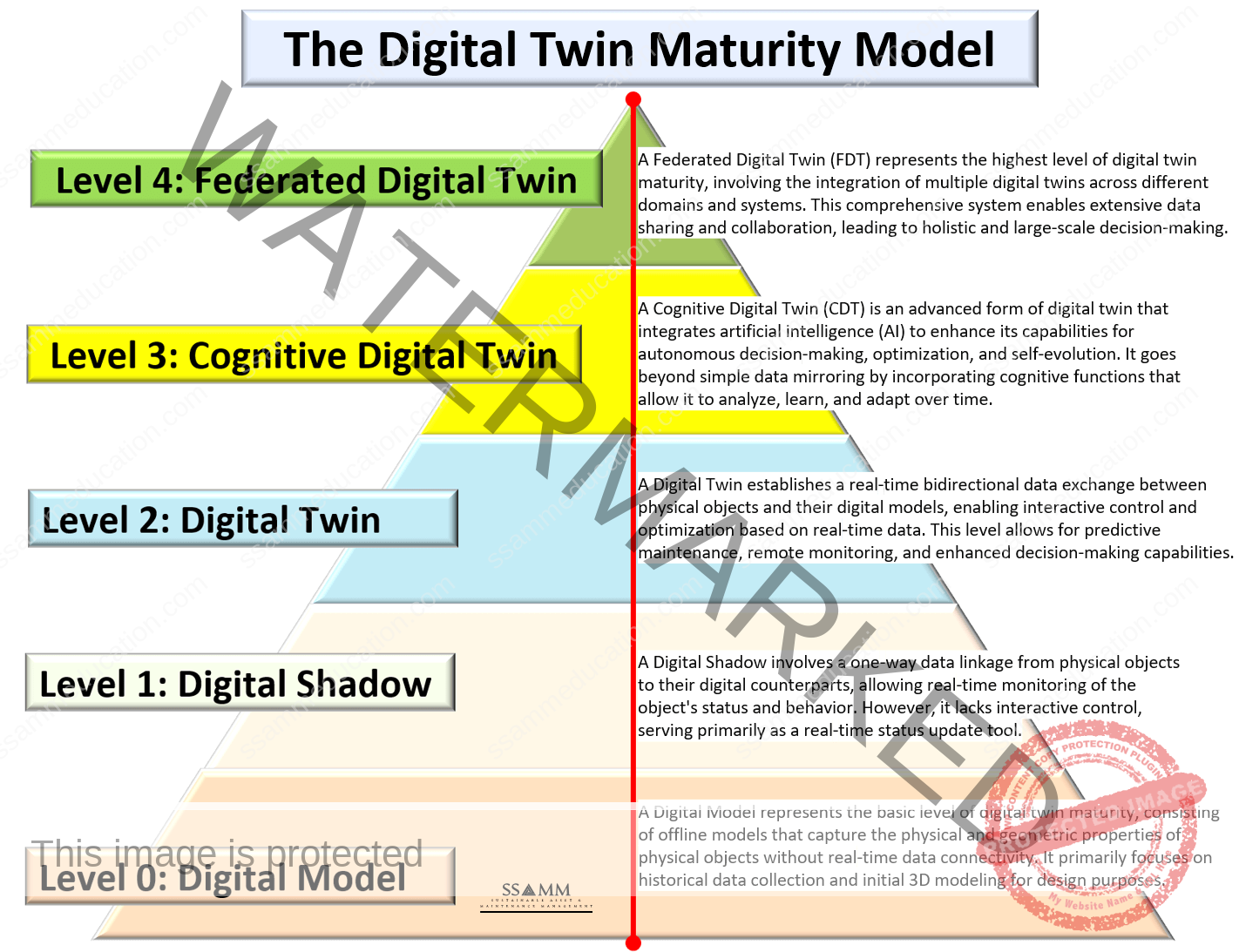

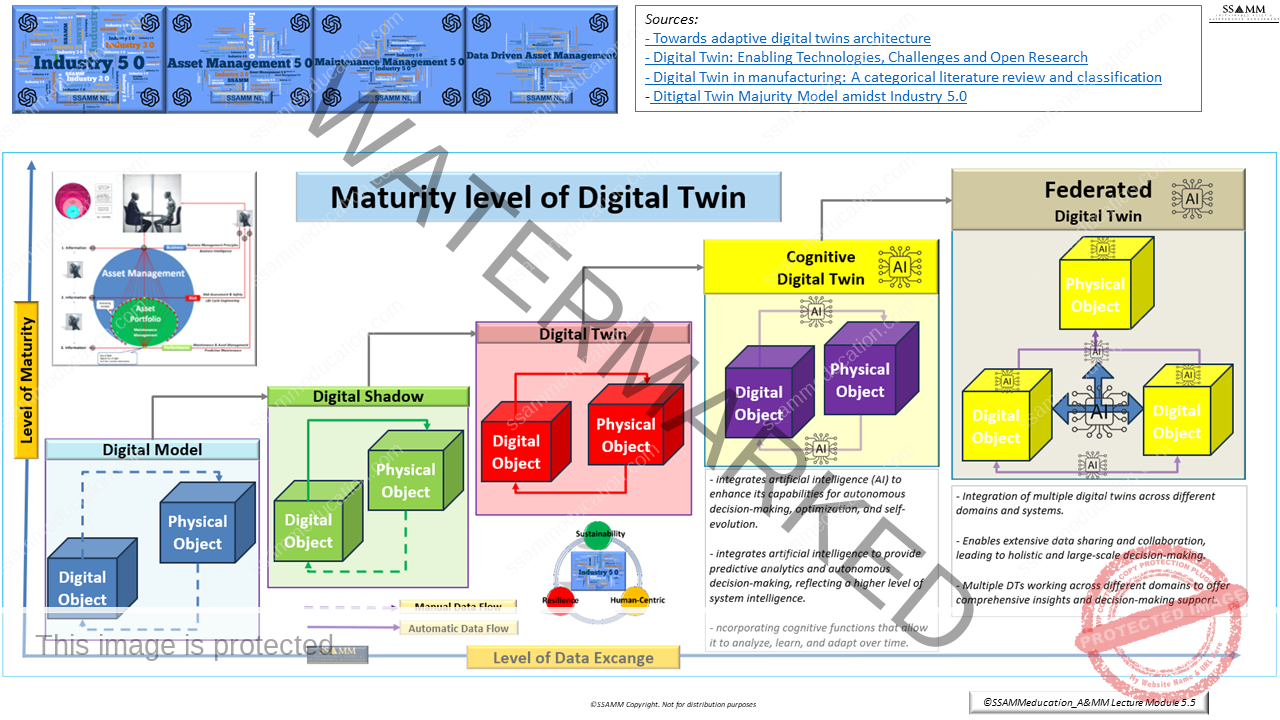

Digital Twin Related

- Reflection: Disruptive Innovation Asset & Maintenance Management

- Collecting Real-Time Data for Predictive Maintenance

- Lean Maintenance 4.0: implementation for aviation industry

- A digital twin-based decision analysis framework for operation and maintenance of tunnels

- Digital building twins and blockchain for performance-based (smart) contracts

- IoT for predictive assets monitoring and maintenance: An implementation strategy

- About auditing in the field of Asset Management

- A Digital Twin Design for Maintenance Optimization

- The difference between Machine Learning(ML) and Deep Learning (DP)

- Digital Twin Definitions: a time perspective

- Definition Digital Twin

- Approach for a Holistic Predictive Maintenance Strategy by Incorporating a Digital Twin

- Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning

- Advances of Digital Twins for Predictive Maintenance

- The 250 classifications of Digital Twin technology

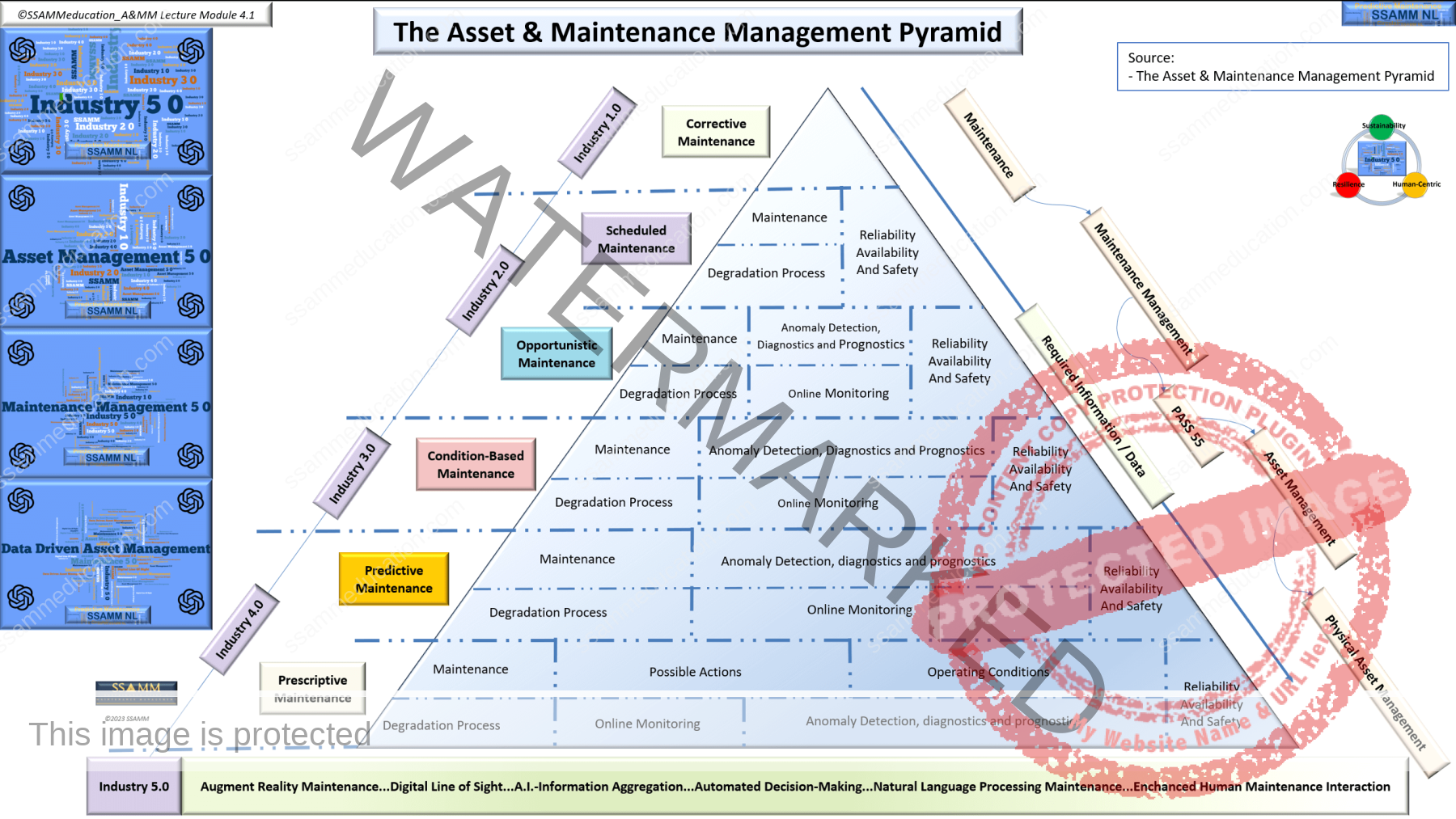

Maintenance Management

- Decision-based framework for Predictive Maintenance Technique selection in Industry 4.0

- Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning

- Recent advances and trends of predictive maintenance from data driven machine prognostics perspective

- Data-driven decision-making for equipment maintenance: Data-driven RCM

- Toward cognitive predictive maintenance: A survey of graph-based approaches

- A deep learning predictive model for selective maintenance optimization

- Inspection schedule for prognostics with uncertainty management

- Development of Digital Twin for Intelligent Maintenance of Civil Infrastructure

- Risk Based Inspection Framework part of evolutions in Maintenance Management; Framework and Process

- KSPMI: A Knowledge-based System for Predictive Maintenance in Industry 4.0

- Sharping the mind: Find The Sweet spot

- The Bathtub Curve Fallacy

- The framework for data-driven maintenance planning and problem-solving in maintenance communities

- The Maintenance Body of Knowledge

- Decision Framework for Predictive Maintenance Method Selection

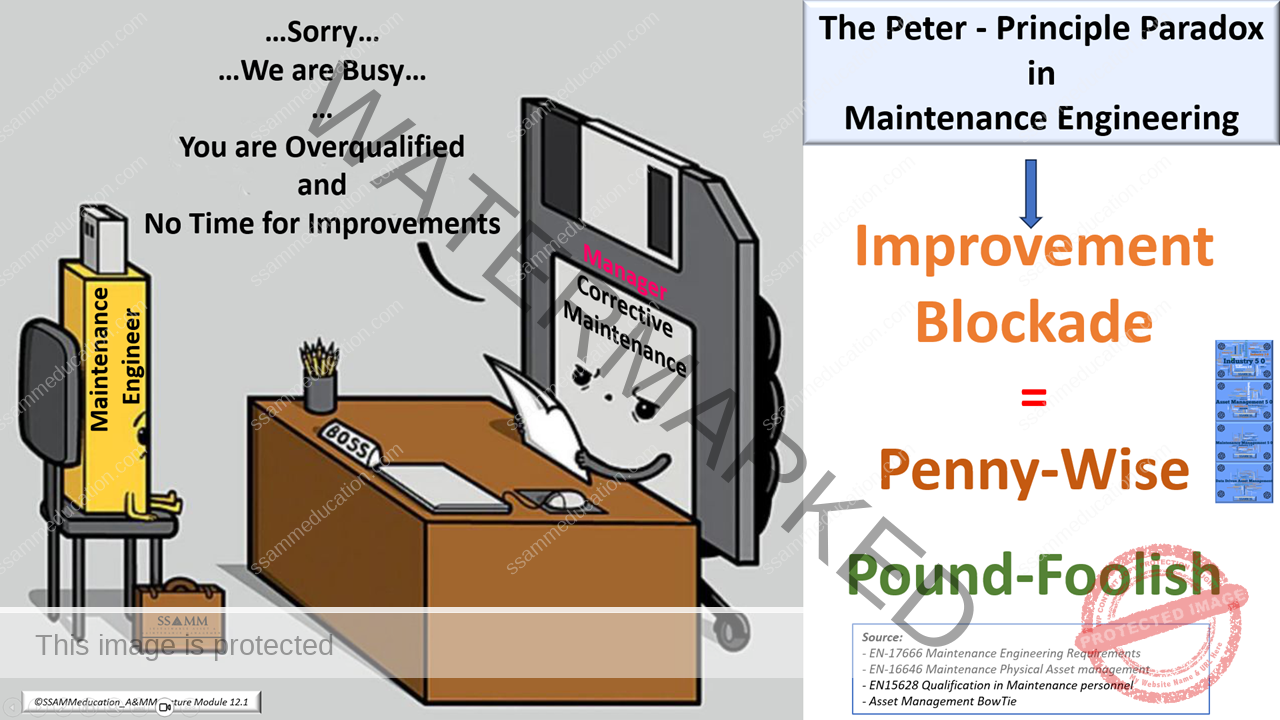

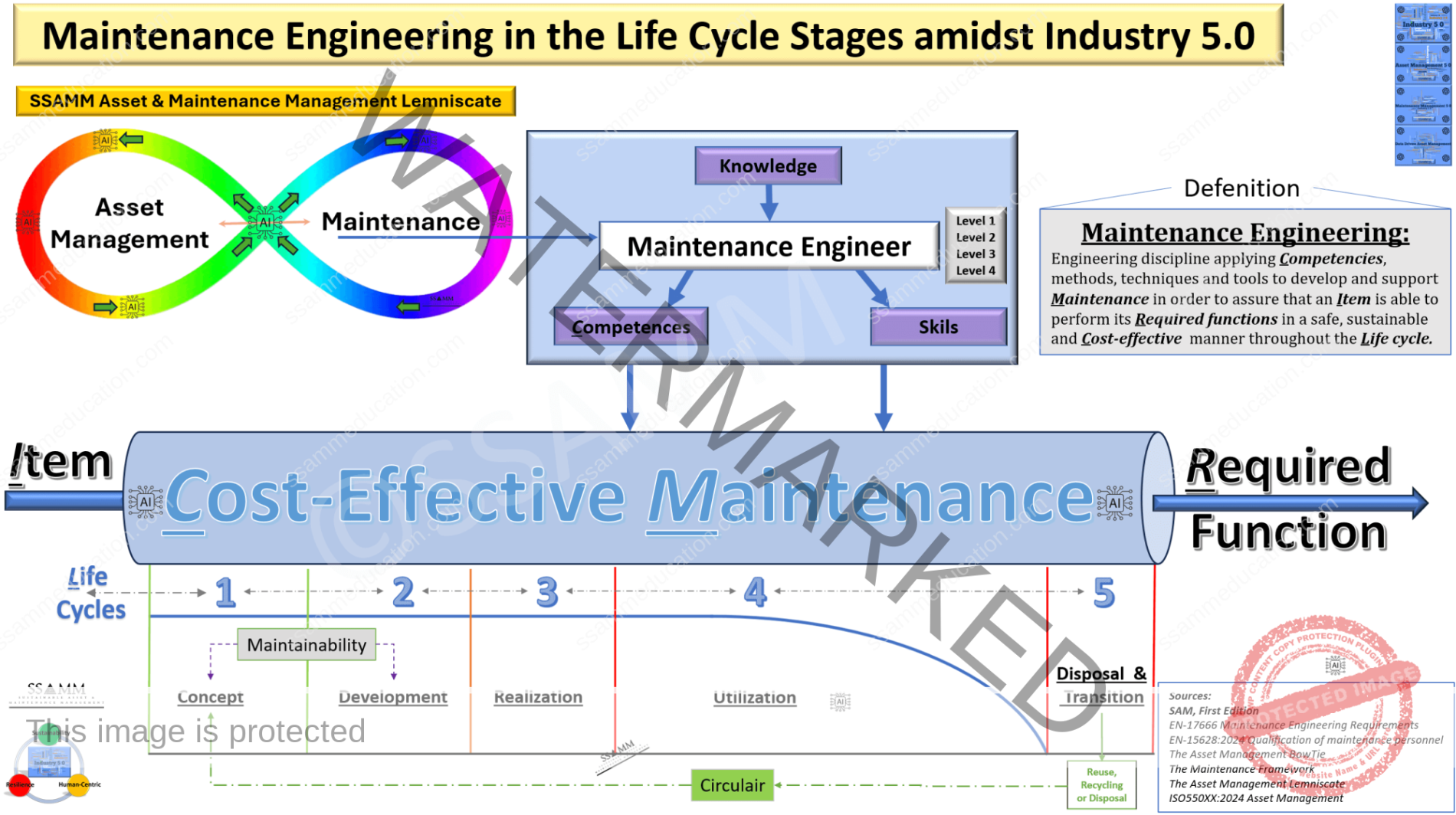

- Maintenance Engineering defined

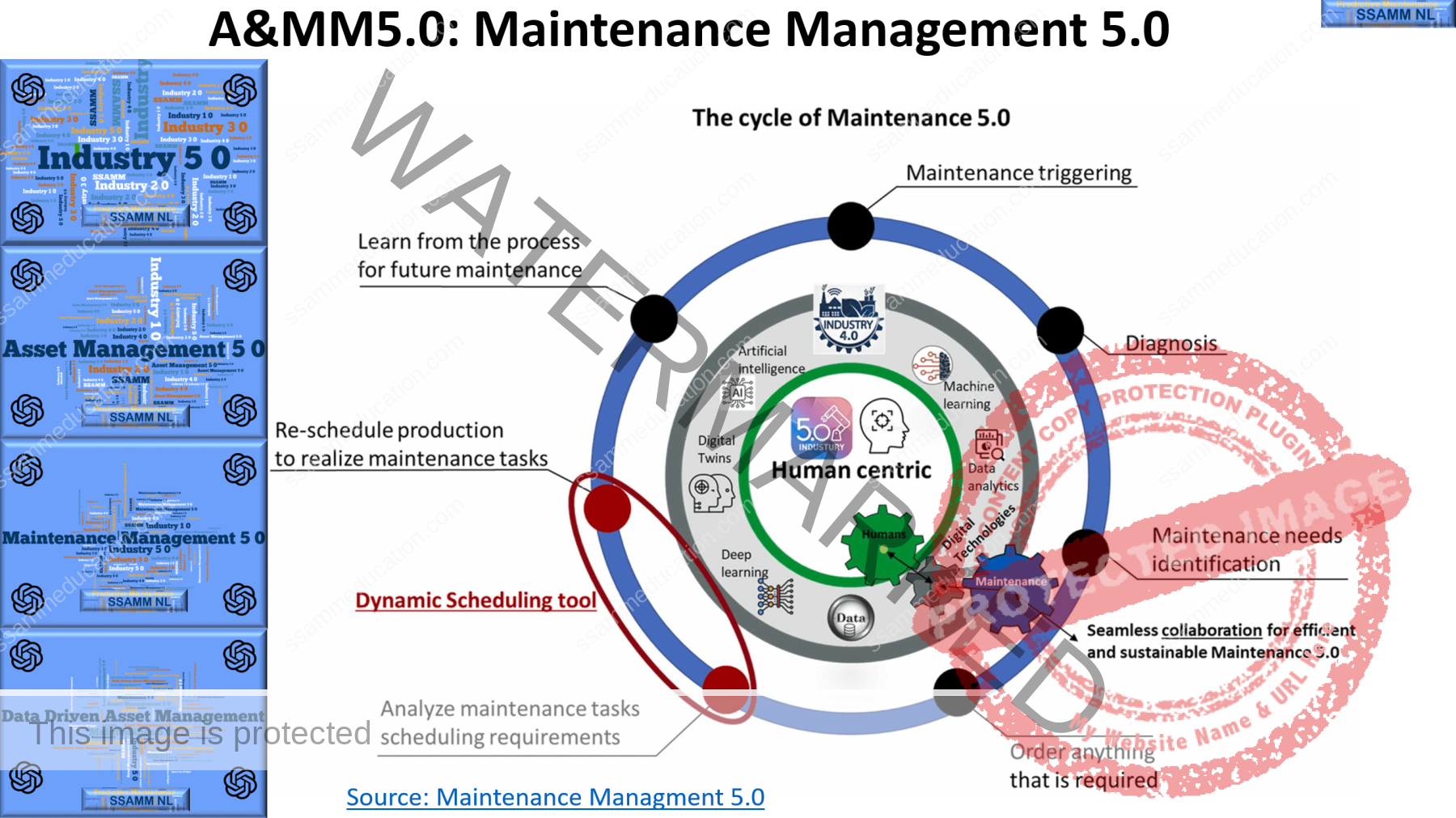

- The Maintenance 5.0 Framework

- The Maintenance 5.0 Cycle

Interpretation Article’s

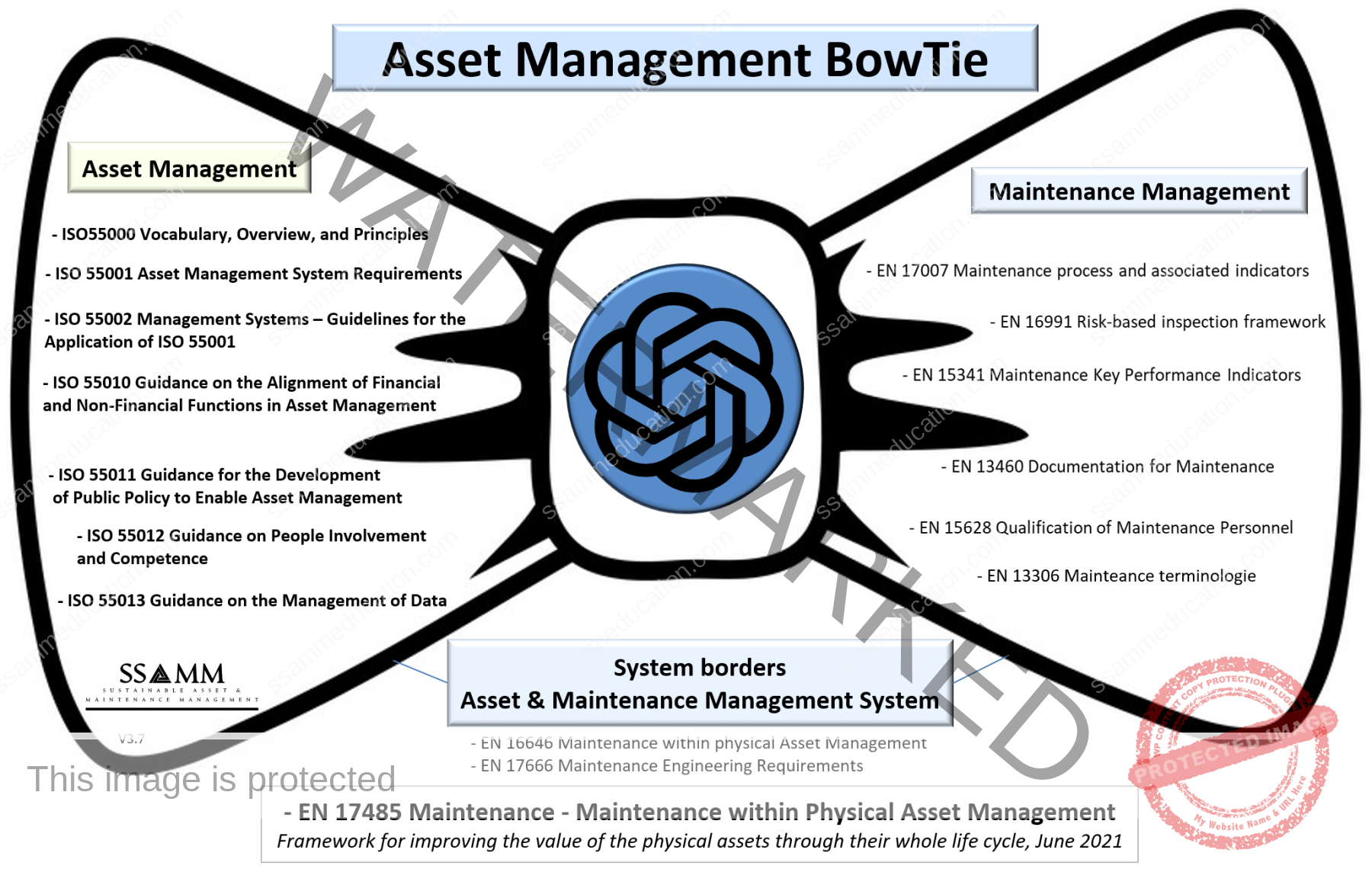

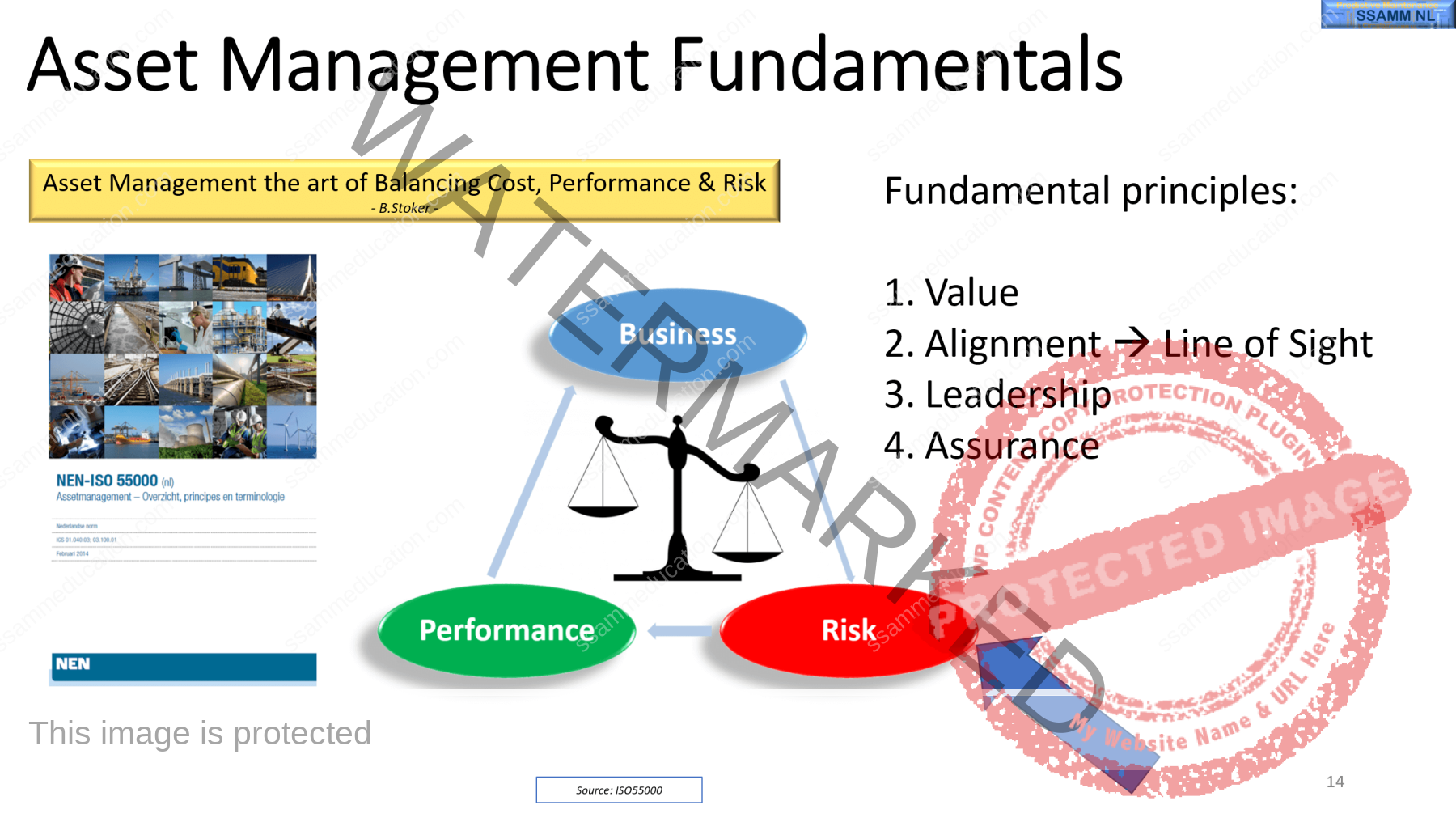

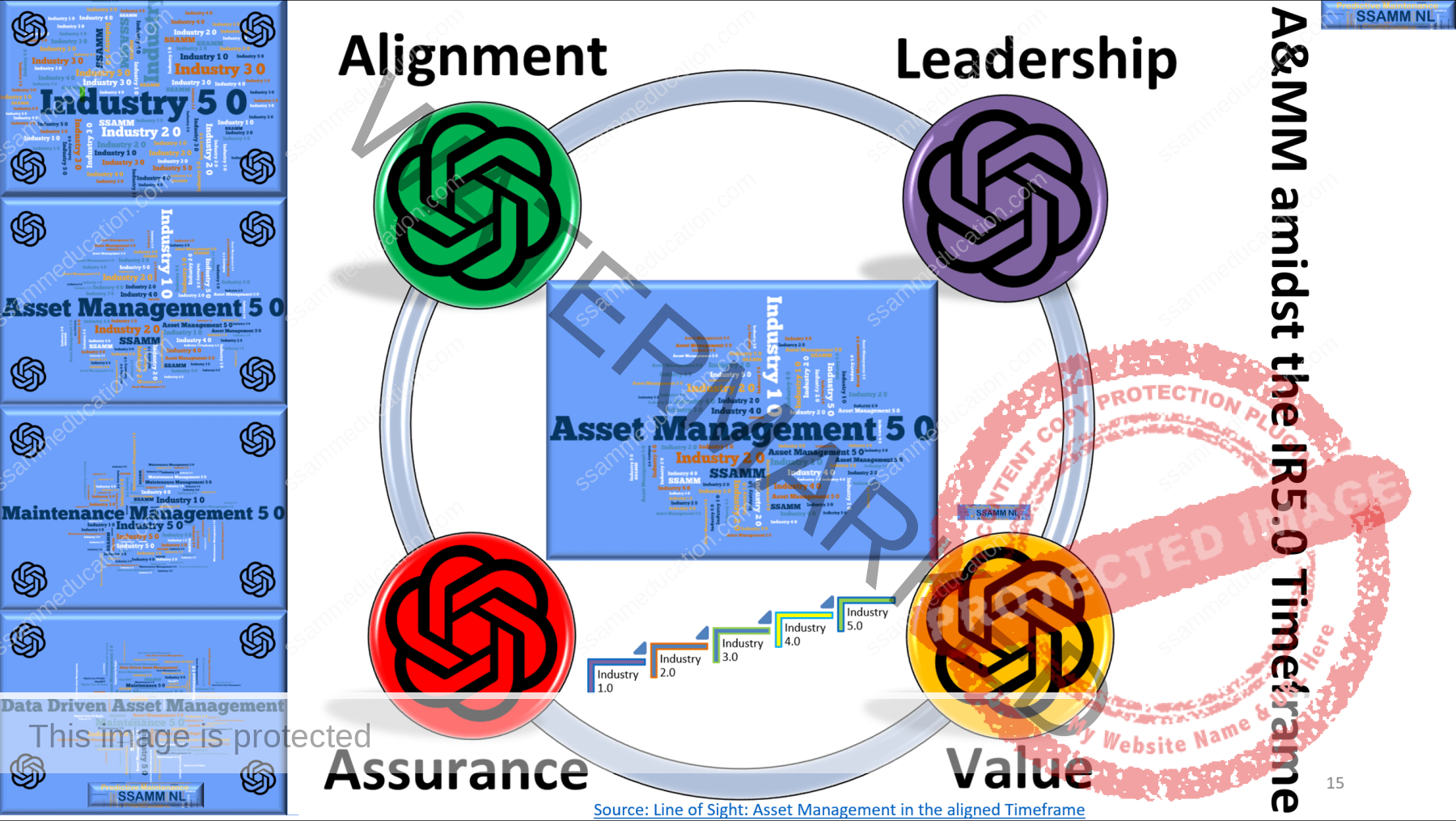

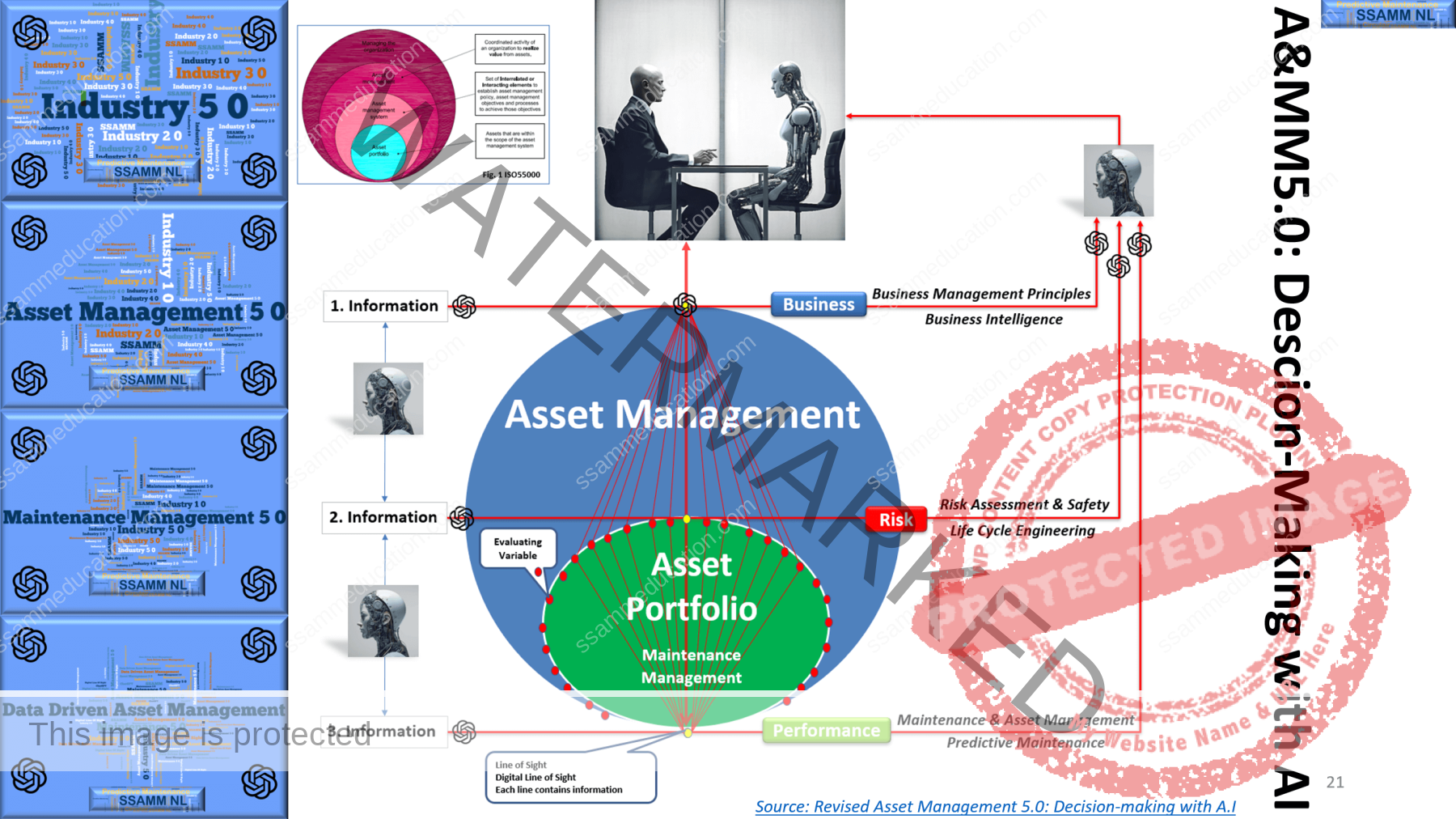

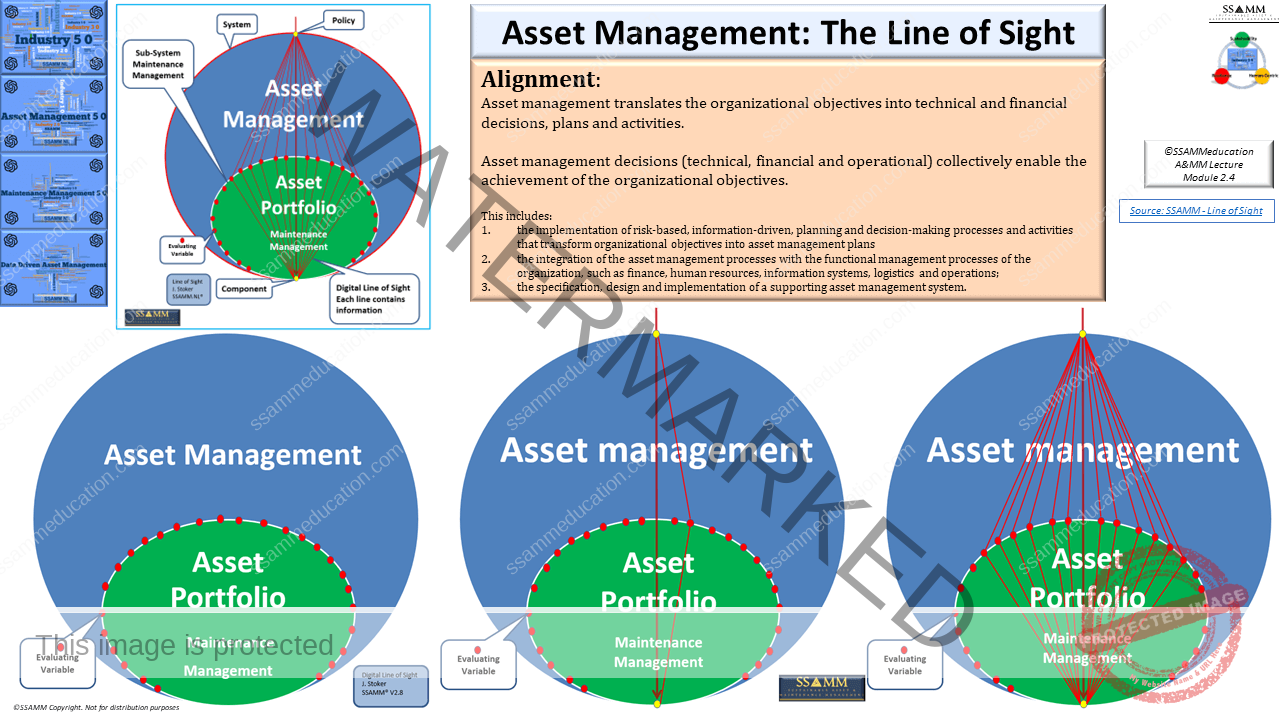

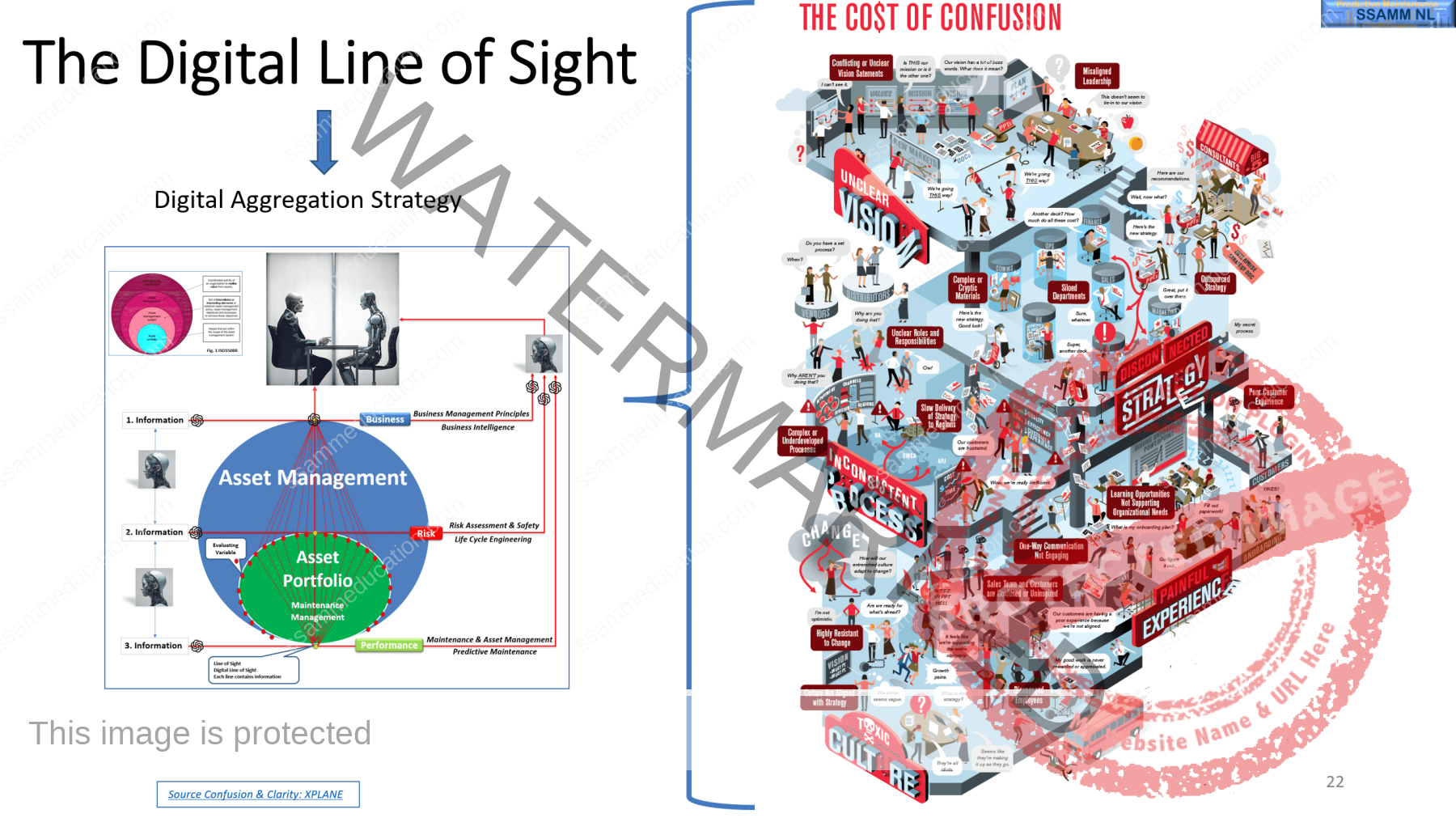

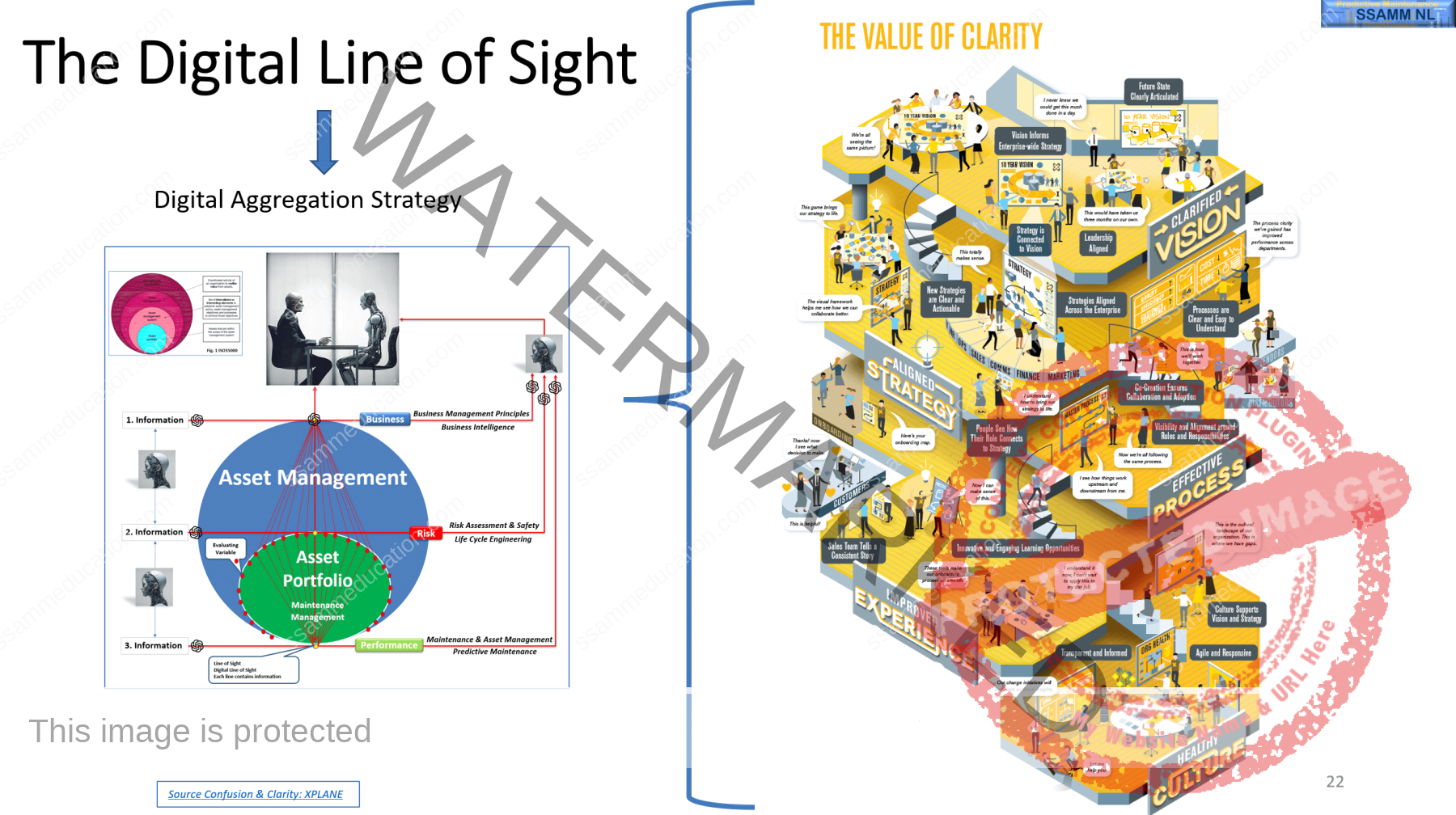

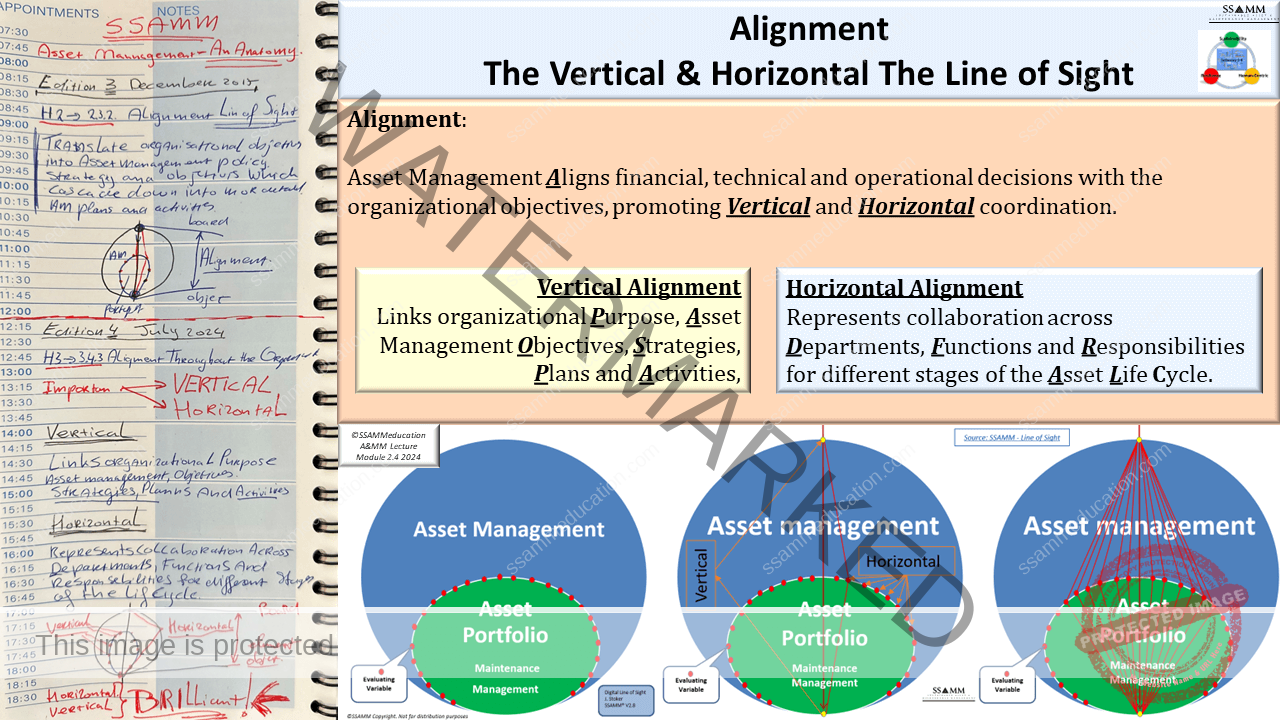

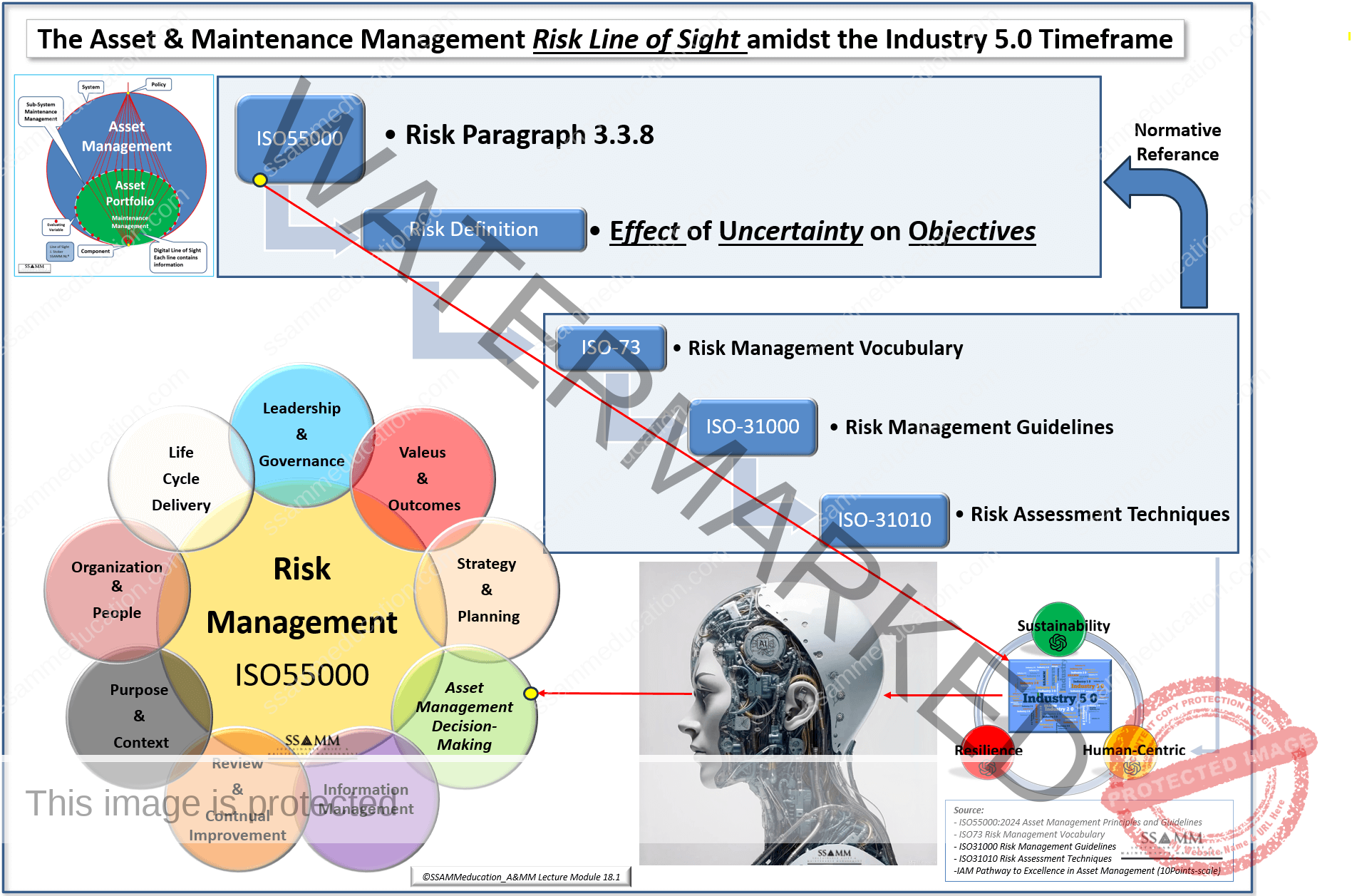

- Line of Sight: Asset Management in the aligned timeframe

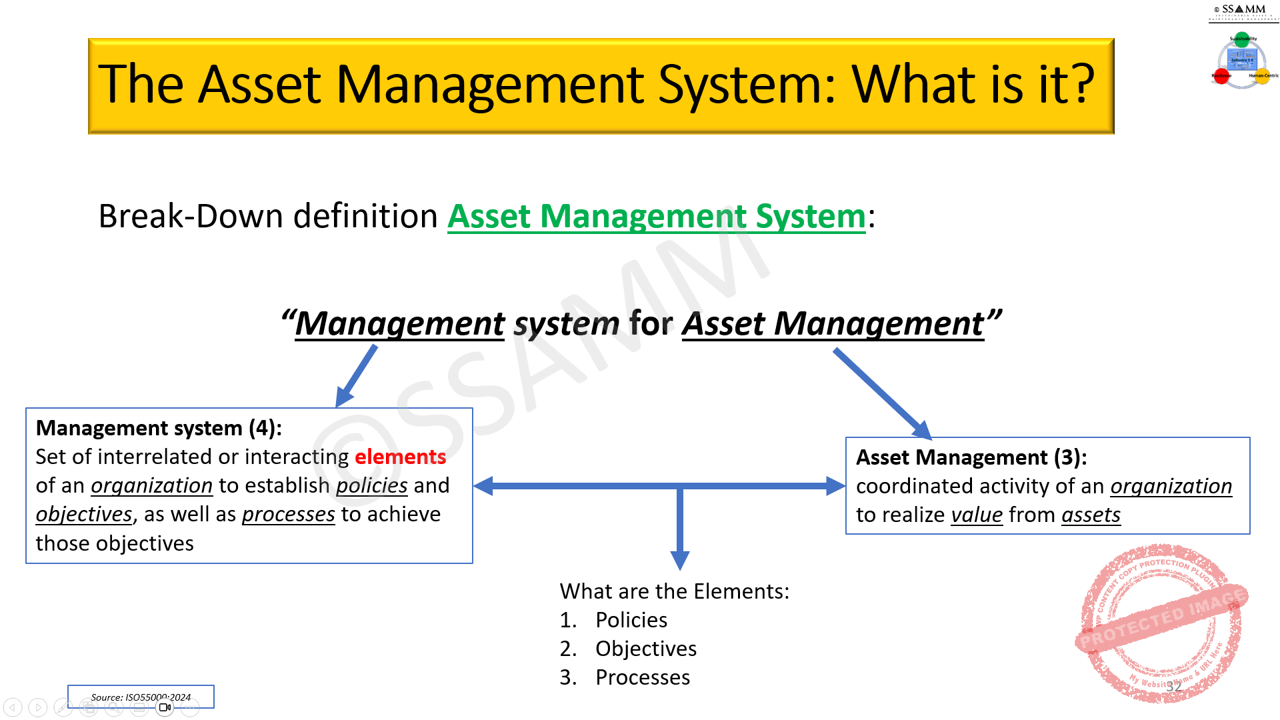

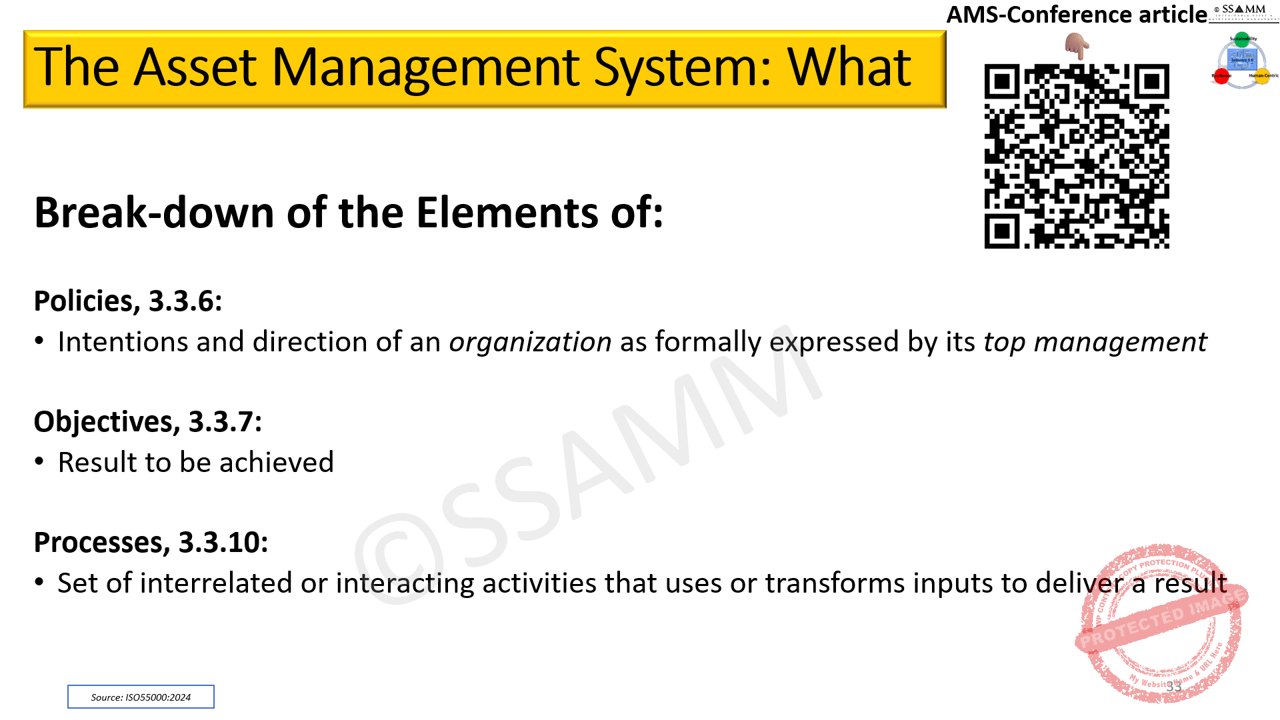

- Interpretation Figure 1 ISO55000

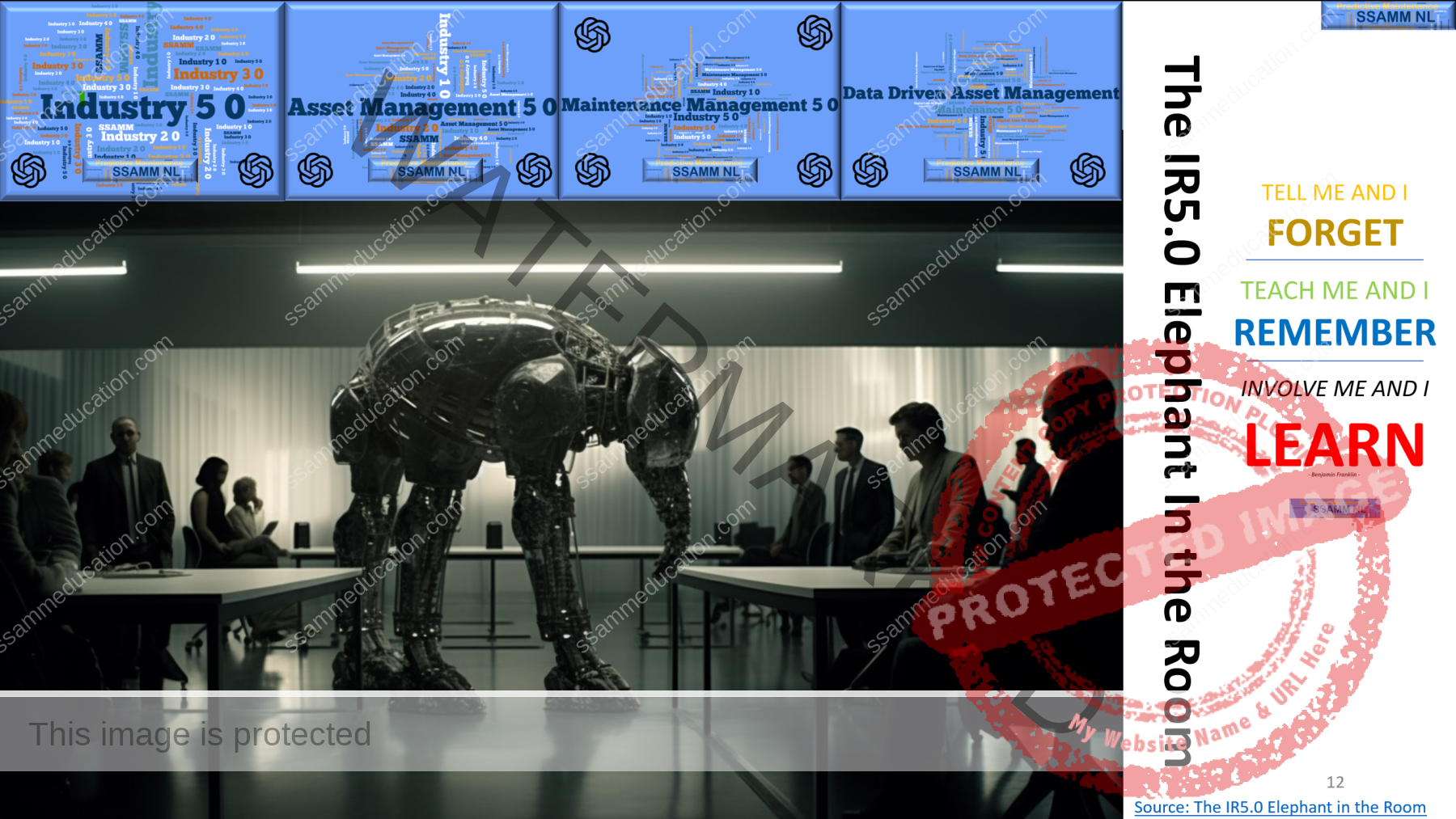

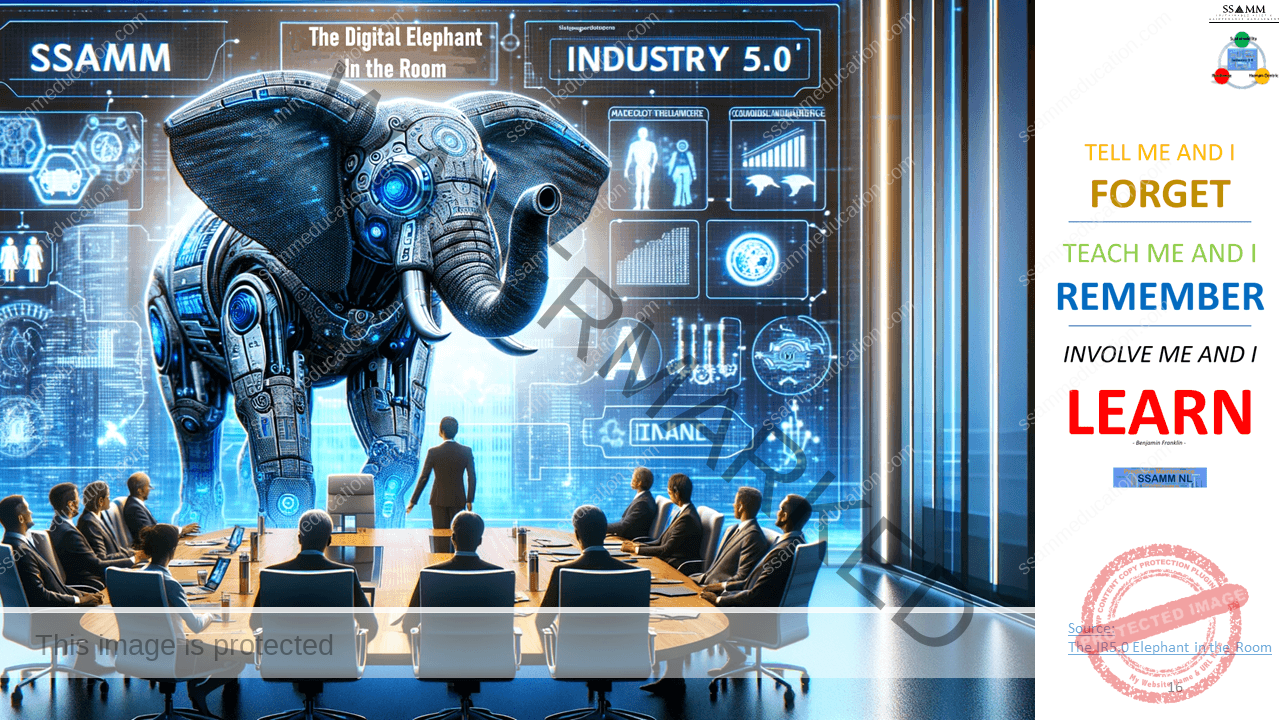

- The elephant in the room

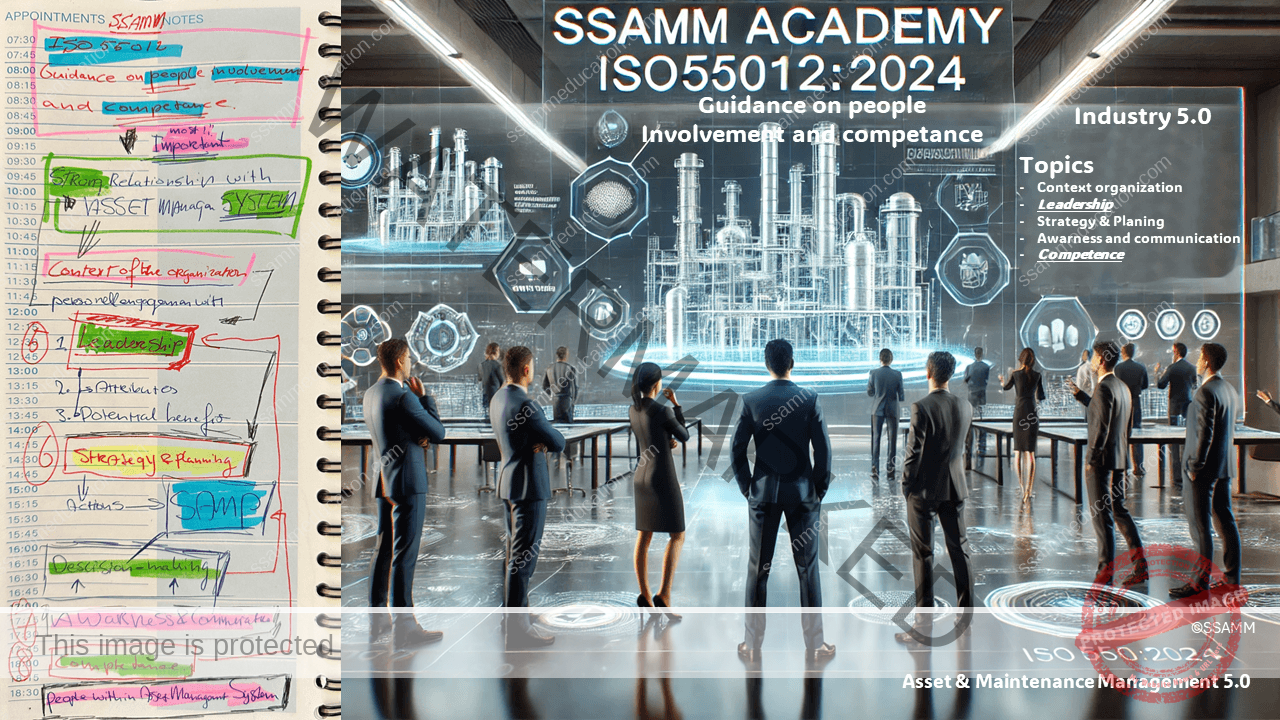

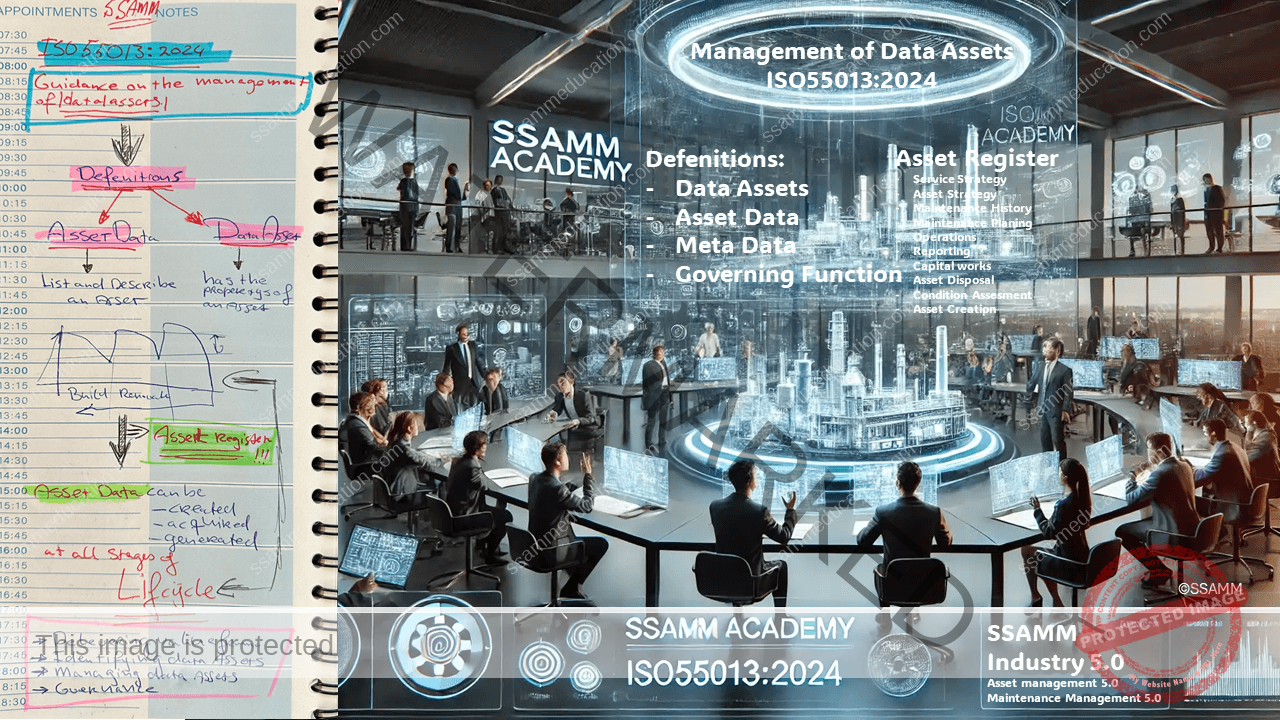

- Asset & Maintenance Management amidst the Industry 5.0 timeframe

- Revised A&MM The Big Picture

- Article IR5.0 Human-Centric

- Explaining Predictive Maintenance using the KISS-Principle

- Asset Management 5.0: Balancing Risk, Performance and Value with IR5.0

- Food for Thoughts: ChatGPT in the field of Asset & Maintenance Management.

Additional Pages To Consult

- Sustainable Asset Management

- The Maintenance Engineer

- The Maintenance Manager

- The Asset Manager

- Industry 5.0

- Circular Asset Management