Publication reference

Title: Building an Asset Management System (AMS)

Author: Benjamin Stoker

Publisher: SSAMM (Click Here)

Publication platform: SSAMM Academy – ssammeducation.com

ISBN/EAN: 978-90-8339-894-5

This restricted web article provides an overview and selected extracts from the publication Building an Asset Management System (AMS) (ISBN/EAN 978-90-8339-894-5). It is made available exclusively to registered SSAMM Academy clients as part of their personal, non-transferable licence.

© 2024 Stoker / SSAMM. All rights reserved.

This content is provided under a personal, non-transferable licence. Unauthorised sharing of logins, screenshots, files or copies (in whole or in part) is not permitted

Despite the increasing relevance of Asset Management Systems (AMS) in both public and private sectors, there remains a considerable degree of ambiguity concerning what an AMS precisely entails, how it should be structured, and how it can be effectively implemented to govern the lifecycle of physical assets.

This contribution offers clarity and direction by presenting a scientifically grounded and standard-aligned approach tailored specifically to maintenance-intensive organizations aiming to professionalize and integrate the management and maintenance of their physical assets.

The proposed framework is anchored in the full ISO 55000:2024 series—including ISO 55000, 55001, 55002, 55010, 55011, 55012, and 55013—and is fully harmonized with the European Maintenance Landscape Model developed under CEN/TC 319. It ensures a coherent translation of organizational strategy into operational execution by aligning asset value realization, risk management, and performance optimization across the full asset lifecycle.

Particular emphasis is placed on the pivotal role of maintenance and maintenance management as defined by EN 17007, EN 17485, EN 17666, and other European standards. These standards provide detailed methodologies for structuring processes, defining performance indicators, and ensuring governance across the management, realization, and support domains. As such, they form the operational foundation of a sustainable, risk-informed, and data-driven AMS. Moreover, the framework is contextualized within the principles of Industry 5.0—emphasizing resilience, sustainability, human-centricity, and AI-enabled decision-making.

Application for Asset Management System inlog

- Fisrst draft Building an Asset Management System 28 December 2024

- Updated 17 February 2025

- Published 2 October 2025

- Published SSAMM Social Media platforms November 2025

Maintenance Fundamentals SAM, First Edition Keynote Āpōpō Congres 2026 Follow Sustainable Asset Management for latest updates

Countdown SSAMM Academy Module 1

Explore the SSAMM Academy Asset Management and Maintenance Management courses.

Click Here for the Smart information page

Author: Ing. Jan Stoker MSc. MEng. AMCP. CFAM. Follow Jan Stoker

Introduction

The primary purpose of the AMS is to systematically enable organizations to maximize value delivery from their assets throughout the entire lifecycle, while simultaneously balancing performance, cost, risks, sustainability, and stakeholder expectations. In this way, the AMS functions as a strategic governance mechanism that translates corporate intent into operational execution, ensuring coherent alignment between long-term objectives, financial integrity, technical performance, safety obligations, and environmental responsibilities.

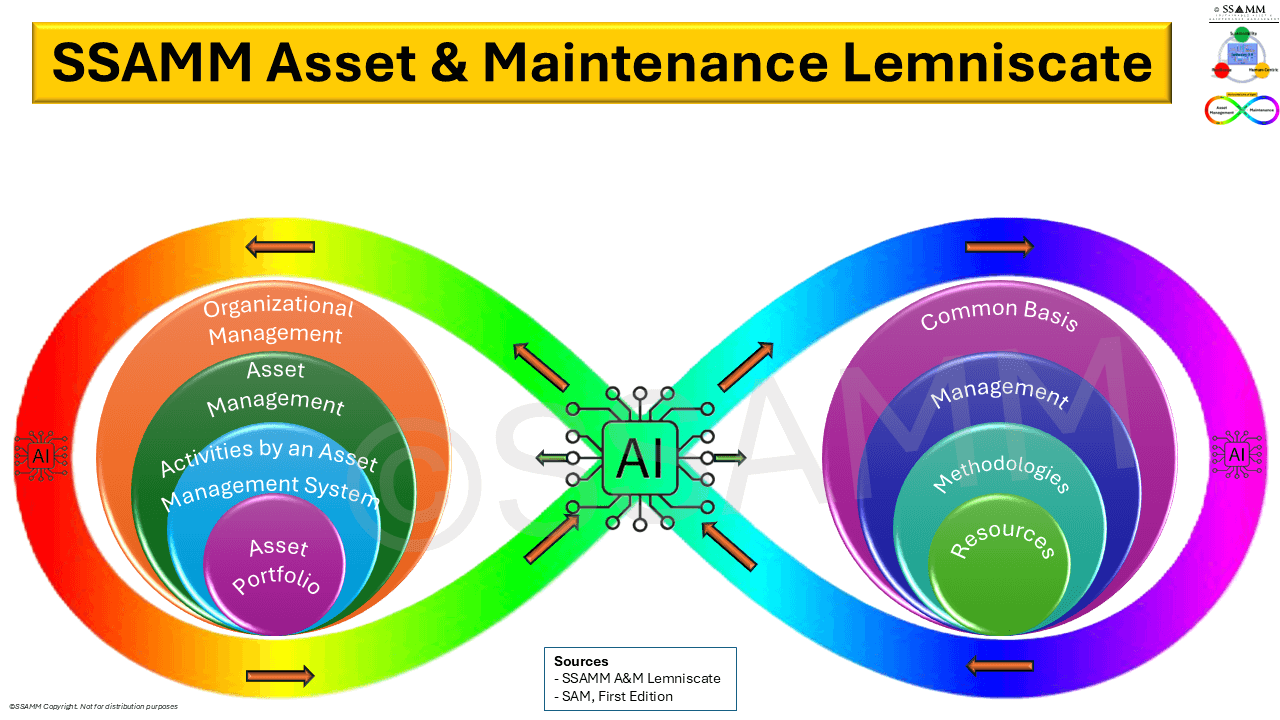

Fig 1: A&MM Lemniscate click to enlarge

At the core of this AMS architecture lies the Asset & Maintenance Management Lemniscate (Figure 1) a conceptual model that visualizes and operationalizes the dynamic interaction between Asset Management (AM) and Maintenance Management (MM) along both the horizontal line of sight (from corporate strategy to daily execution) and the vertical line of sight (from asset portfolio to individual asset function). The Lemniscate model enables organizations to clearly map how strategic asset management decisions are continuously informed by operational maintenance feedback, creating closed-loop governance for continuous improvement, knowledge integration, and organizational learning.

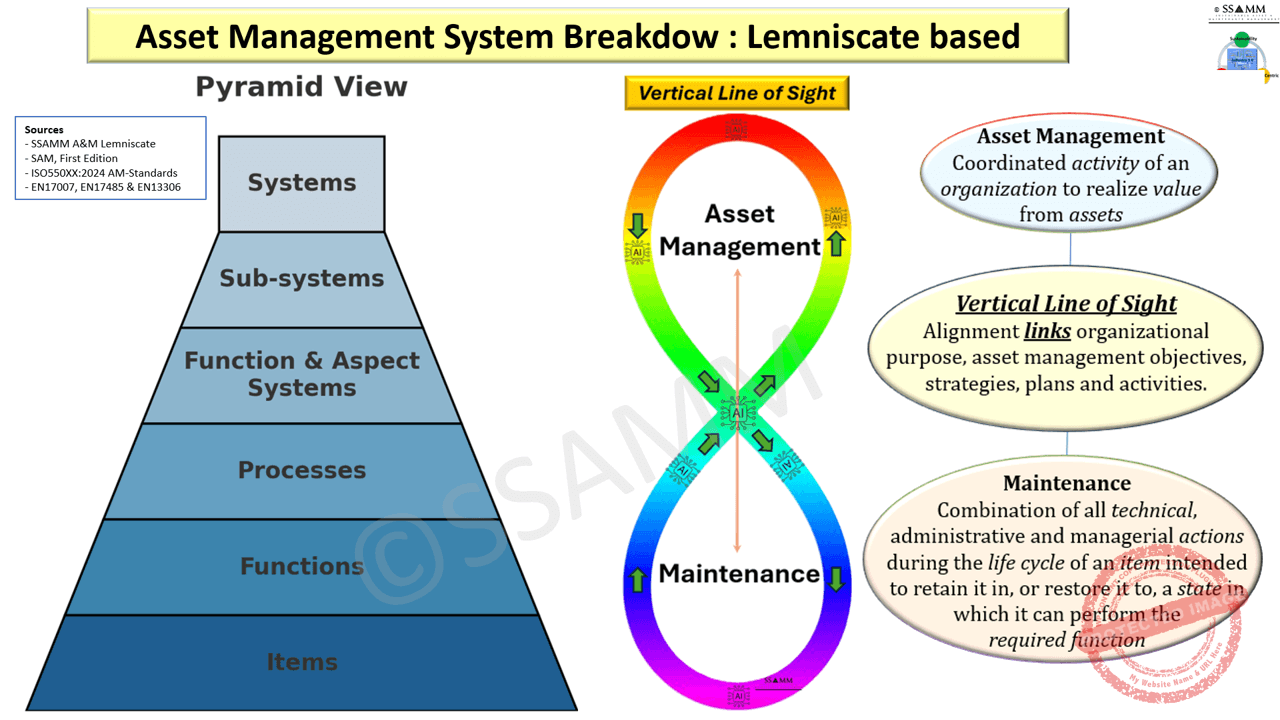

To translate this conceptual governance model into concrete operational practice, the Maintenance Landscape Model (Figure 2) provides a normative and methodological structure for maintenance processes, as formally established within the European CEN/TC 319 suite of standards. T

Fig.2: Maintenance Landscape Model click to enlarge

Together, the Lemniscate (Figure 1) and the Maintenance Landscape Model (Figure 2) form the operational and systemic backbone of the AMS, ensuring full alignment between governance, operational execution, continuous improvement, and learning processes.

Normatively, this integrated framework is fully aligned with the comprehensive ISO 55000:2024 series, encompassing:

-

ISO 55000:2024 – Vocabulary, Overview and Principles

-

ISO 55001:2024 – Requirements for Asset Management Systems

-

ISO 55002:2024 – Application Guidelines

-

ISO 55010:2024 – Alignment of Financial and Non-Financial Functions

-

ISO 55011:2024 – Guidance for Public Policy

-

ISO 55012:2024 – Guidance on People Involvement and Competence

-

ISO 55013:2024 – Guidance on Data Asset Management

Taken together, these normative frameworks establish a state-of-the-art Asset Management System capable of delivering robust, sustainable, and resilient asset performance while fully embracing the challenges and opportunities presented by Industry 5.0 — including artificial intelligence (AI), cognitive analytics, digital twins, human-centric leadership, and organizational learning.

Throughout this article, a systematic exposition is provided for the design, implementation, governance, operation, and continual improvement of such an integrated AMS, ensuring that organizations possess the necessary structures, competencies, and capabilities to meet both current and emerging demands in physical asset management.

Deepening the subjects where this article is build on please reed the next articles:

- The maintenance Framework Click Here

- The ISO550XX:2024 Click Here

- The Asset & Maintenance Management Lemniscate Click here

- Industry 5.0 Click Here

1. Understanding the Asset Management System (AMS)

The establishment of an effective Asset Management System (AMS) is central to ensuring that physical assets contribute optimally to the realization of organizational objectives throughout their entire lifecycle. The AMS serves as the structured and integrated organizational framework that enables alignment between strategic ambitions, operational realities, and the continuous optimization of asset-related value creation.

Within this context, the AMS provides the systematic foundation for translating organizational policies, business objectives, and stakeholder expectations into actionable asset management processes and decisions. It integrates governance, risk management, lifecycle considerations, financial stewardship, and maintenance management into one coherent system that supports sustainable organizational performance.

In modern asset-intensive organizations—particularly within the paradigm of Industry 5.0—the AMS must be designed to operate within increasingly complex environments characterized by rapid technological advancements, growing sustainability demands, resilience requirements, human-centric work systems, and advanced data-driven decision-making supported by artificial intelligence (AI) and cognitive digital twins.

To adequately address these complexities, structured models and standards have been developed to guide organizations in systematically designing, implementing, and improving their AMS. The ISO 55000:2024 series provides the fundamental vocabulary, principles, requirements, and application guidelines for establishing such systems. However, the operationalization of these requirements, particularly concerning the role of maintenance, is further detailed through European standards such as EN 17485:2021 and EN 17007:2017, supported by the broader CEN/TC 319 Maintenance Landscape Model.

In this framework, the Asset & Maintenance Management Lemniscate serves as an important conceptual model that visualizes the dynamic interplay between the strategic and operational dimensions of asset and maintenance management, while the Maintenance Landscape Model structures the specific processes, functions, and responsibilities necessary for effective maintenance execution.

The following sections provide a systematic exploration of the AMS, starting with its fundamental definitions and principles as defined by ISO 55000:2024.

1.1 Definition and Fundamental Principles

According to ISO 55000:2024, an Asset Management System (AMS) is explicitly defined as:

Management System for Asset Management

Additionally, ISO 55000:2024 defines a management system as:

Set of interrelated or interacting elements of an organization to establish policies and objectives, as well as processes to achieve those objectives.

In its essence, an AMS represents a systematic construct that enables organizations to optimize value realization from their physical assets throughout the entire asset lifecycle. By integrating organizational policies, governance structures, resource allocation, and operational processes, the AMS ensures that asset-related decisions remain fully aligned with overarching business strategies and stakeholder expectations.

The AMS serves multiple concurrent purposes:

-

It enables organizations to translate high-level corporate objectives into operational asset-related activities.

-

It facilitates the integration of multiple disciplines—including maintenance, operations, finance, risk management, safety, and sustainability—into one coherent system of coordinated processes.

-

It supports structured decision-making across all lifecycle stages of assets, from initial acquisition to decommissioning, ensuring that investments, performance, and risks are managed transparently and consistently.

1.1.1. Core Principles Governing the AMS

The effective design, implementation, and continual improvement of an AMS are governed by several fundamental principles, as articulated within ISO 55000:2024 and operationalized through standards such as EN 17485 and EN 17007:

-

Value Creation and Realization:

The AMS must systematically maximize sustainable value from assets, taking into account financial performance, operational efficiency, safety, environmental responsibility, and social outcomes throughout the entire lifecycle. -

Alignment with Organizational Objectives:

All asset-related decisions and processes are derived from, and aligned with, the organization’s strategic direction, ensuring internal consistency across technical, operational, financial, and human dimensions. -

Leadership, Governance and Commitment:

Strong leadership engagement across all hierarchical levels is essential to maintain the integrity of the AMS, ensuring adequate resourcing, policy adherence, and organizational accountability. -

Risk-Based and Informed Decision-Making:

Asset management decisions are systematically based on evidence, structured risk assessments, and scenario analyses that consider uncertainties, trade-offs, and stakeholder expectations. -

Stakeholder Engagement:

The AMS ensures that relevant stakeholders are identified, consulted, and engaged throughout the asset lifecycle, ensuring alignment of interests, transparency, and shared ownership of outcomes. -

Continuous Improvement:

The AMS promotes adaptive learning through structured feedback loops, data analytics, performance monitoring, and systematic reviews, allowing for continuous optimization of asset-related processes and capabilities. -

Sustainability and Long-Term Resilience:

Asset management under Industry 5.0 conditions increasingly incorporates environmental stewardship, social responsibility, workforce empowerment, and resilience against external shocks into the strategic and operational management of physical assets.

In the subsequent sections, the structural elements and operationalization of these principles will be further elaborated, including the strategic role of EN 17485 in developing a fully integrated and functionally coherent AMS.

1.2 Integration with EN17485

The European Standard EN 17485:2021 Maintenance — Maintenance within physical asset management — Framework for improving the value of physical assets throughout their whole life cycle provides a systematic and integrative methodological framework for embedding maintenance within the broader context of physical asset management. Unlike ISO 55001:2024, which primarily stipulates what must be established in an Asset Management System (AMS), EN 17485 explicitly guides organizations how to operationalize these requirements, particularly in relation to maintenance. EN 17485 therefore serves as a critical bridge between the ISO 5500x series and the family of European maintenance standards (EN 13306, EN 17007, EN 16646, among others), translating strategic objectives into concrete maintenance processes and practices.

EN 17485 offers organizations a structured framework for achieving:

-

Systematic alignment of maintenance with business objectives;

-

Integrated decision-making across corporate planning, production, finance, and technical functions;

-

Improved transparency, simulation, visualization, and uncertainty management in asset-related decisions;

-

Enhanced sustainability and long-term value realization from physical assets.

The standard closes the methodological gap left open by EN 16646, which originally positioned maintenance conceptually within physical asset management, but lacked detailed implementation guidance. EN 17485 thus directly supports organizations in translating ISO 55001 requirements into a comprehensive, operational Asset Management Process.

The Strategic Asset Management Process Click to enlarge

1.2.1 The Asset Management Process: A Distinction from the SAMP

It is important to emphasize that EN 17485 focuses primarily on the Asset Management Process, not the Strategic Asset Management Plan (SAMP) itself. Where the SAMP constitutes a high-level strategic document that connects organizational objectives to asset management objectives (as described in ISO 55002:2024), the Asset Management Process, as operationalized through EN 17485, addresses how those strategic intentions are methodically executed and sustained across the organization.

The Asset Management Process under EN 17485 encompasses:

-

The development and alignment of corporate policies, organizational plans, and critical success factors;

-

The translation of business and stakeholder requirements into maintenance and asset strategies;

-

The systematic deployment of these strategies through operational, tactical, and technical levels.

Through this framework, EN 17485 ensures that maintenance is not an isolated operational function but an integral, cross-functional contributor to organizational value creation.

1.2.2 Alignment Across Organizational Levels and Functions

EN 17485 explicitly integrates maintenance into all levels of organizational management, including:

-

Corporate Planning Management

-

Plant Management

-

Technical Management

-

Production Management

-

Financial Management

-

Asset Management

-

Maintenance Management

-

Quality Management

By embedding maintenance into these diverse managerial functions, EN 17485 promotes cross-functional cooperation, facilitates integrated investment and maintenance planning, and supports transparent and consistent decision-making processes across the enterprise.

This multilevel integration enhances the credibility and accountability of maintenance within the organization, allowing maintenance to contribute effectively to financial, operational, and sustainability objectives.

1.2.3 Strategic Benefits of EN 17485 Application

The implementation of EN 17485 produces substantial organizational benefits, including:

-

Economically more efficient and profitable use of capital assets through improved asset turnover and return on investment;

-

Accurate long-term lifecycle decision-making, enabling optimized capital allocation and reduced financial risk;

-

Integrated asset, production, and maintenance planning, ensuring operational coherence;

-

Enhanced organizational resilience through improved decision transparency, stakeholder confidence, and extended enterprise capabilities;

-

Sustainability improvements, both in environmental and economic terms, supporting long-term operational viability.

In this way, EN 17485 provides a robust framework for aligning maintenance strategies with both current operational demands and future organizational aspirations.

1.2.4 Maintenance as Strategic Enabler of Organizational Objectives

Maintenance, under the EN 17485 framework, is positioned as a strategic enabler rather than solely as a cost center. Maintenance activities directly contribute to:

-

Increasing production availability and OEE (Overall Equipment Effectiveness);

-

Reducing unnecessary capital investment through optimized asset utilization;

-

Improving delivery reliability and customer satisfaction;

-

Supporting regulatory compliance and environmental stewardship;

-

Enhancing workforce engagement, competence, and safety.

By actively managing asset health and performance, maintenance reinforces the asset portfolio’s capacity to deliver on organizational critical success factors (CSFs), which in turn underpin strategic competitiveness.

1.2.5 Embedding Maintenance into the Multilevel Strategic Deployment Process

EN 17485 articulates a multilevel strategic deployment process where:

-

Corporate policy, organizational objectives, and CSFs serve as the primary inputs at the corporate level;

-

The Asset Management Policy and the Asset Management Process translate these into operational and asset-specific terms;

-

The SAMP consolidates asset management objectives at the portfolio level, while the Asset Management Plan (AMP) addresses system-specific execution at the asset system level.

Within this construct, maintenance strategies are developed in full alignment with asset lifecycle stages, technological developments, market conditions, and organizational capacity. Maintenance planning thus becomes an iterative, dynamic activity directly contributing to the continuous improvement of the AMS.

1.2.6 EN 17485 as Integrative Bridge within the Standards Landscape

Finally, EN 17485 occupies a normative integrative position within the Asset Management Standards Landscape. It links:

-

The ISO 5500x series (ISO 55000, ISO 55001, ISO 55002, ISO 55010, ISO 55011, ISO 55012, ISO 55013) that establish the AMS principles, requirements, guidelines, alignment, policy development, people involvement, and data governance;

-

With the CEN/TC 319 maintenance standards family (including EN 17007, EN 13306, EN 17666, EN 17948, EN 15341, EN 15331, EN 13269, EN 15628, etc.) that provide structured maintenance management, process design, performance indicators, and competence requirements.

Through this integration, EN 17485 strengthens the methodological foundation for organizations striving to develop state-of-the-art, Industry 5.0-compliant Asset Management Systems.

1.3 Asset Management System in the Context of EN17007

The EN17007 standard explicitly details systematic management practices for maintenance activities within an AMS framework. It outlines critical maintenance processes including condition monitoring, preventive maintenance, predictive maintenance, and corrective maintenance. These structured processes are explicitly aimed at maintaining, restoring, and enhancing asset performance and reliability throughout their operational lifecycle.

Integrating AMS with EN17007 ensures:

- Clear and standardized guidelines for executing maintenance activities.

- Enhanced accuracy and reliability of performance measurement metrics, facilitating ongoing improvement.

- Improved strategic alignment and integration between asset management goals and operational maintenance activities.

1.4 Key Elements of an Asset Management System

ISO 55001:2024 identifies several interconnected essential elements within an effective AMS:

- Management System Framework: Structured policies, objectives, and procedures guiding consistent asset-related decision-making.

- Decision-Making Framework: Clearly defined methodologies and criteria supporting informed asset management decisions to optimize value and manage risk effectively.

- Stakeholder Engagement: Systematic and proactive stakeholder involvement, clear communication of requirements, and active participation across the asset management lifecycle.

- Performance Monitoring and Measurement: Continuous evaluation against established benchmarks, ensuring accountability, transparency, and continual improvement.

- Documentation and Information Management: Comprehensive documentation and accessible information systems supporting informed decision-making and regulatory compliance.

1.5 Relationship Between AMS, Assets, and Maintenance Management

The Asset Management System serves as the strategic organizational framework, integrating and coordinating maintenance management activities to sustain asset performance, reliability, and long-term sustainability. ISO 55000:2024 explicitly defines AMS as a coordinated system aimed at maximizing value from assets through strategic alignment, structured decision-making, and optimized performance management.

Maintenance management operationalizes the AMS strategic objectives through systematic, actionable, and measurable processes, which is precisely where EN17007 provides critical clarity and structured guidance. EN17007 explicitly outlines comprehensive, standardized processes for maintenance activities, ensuring these activities are directly aligned with the strategic objectives set by ISO 55000 and ISO 55001. By clearly defining maintenance processes into distinct categories—Management, Realization, and Support—EN17007 provides a structured method to implement AMS objectives practically.

This integration enhances the clarity and effectiveness of AMS implementation by establishing transparent and well-defined maintenance processes that can be systematically managed, measured, and continuously improved. It ensures that maintenance activities are not isolated, operational tasks but integral components of strategic asset management. The structured process breakdown provided by EN17007 facilitates clear communication of roles, responsibilities, objectives, and performance metrics across organizational levels, significantly enhancing the alignment between operational maintenance tasks and strategic asset management goals.

The interrelationship is structured as follows:

- Assets: Key organizational resources driving strategic and operational objectives, delivering value, and sustaining long-term organizational performance.

- Maintenance Management: Systematic processes defined explicitly by EN17007 to ensure optimal functionality, reliability, longevity, compliance, and effectiveness of assets.

- Asset Management System (AMS): The overarching framework articulated by ISO 55000:2024 and ISO 55001:2024, integrating planning, execution, and evaluation of maintenance management activities within broader strategic organizational objectives.

Embedding maintenance management within the AMS framework, as structured by ISO 55000 and operationally detailed by EN17007, significantly enhances organizational benefits. It ensures comprehensive lifecycle management, improved strategic decision-making, sustained asset performance, increased adaptability, and strengthened organizational resilience. The explicit alignment and integration of ISO 55000:2024, ISO 55001:2024, EN17007, and EN17485 provide organizations with the essential tools and methodologies to confidently achieve operational excellence and ensure sustainable long-term success.

2. Structuring an Asset Management System using the SSAMM A&MM Breakdown Lemniscate

This chapter focuses on how to design and further build a complete Asset Management System (AMS).

For that purpose, the SSAMM A&MM Breakdown Lemniscate is introduced as the primary framework.

It ensures that the AMS is not just a collection of processes and documents, but a coherent system that links strategic objectives with operational reality.

The lemniscate combines two complementary perspectives:

-

On the left-hand side, the Asset Management perspective, focusing on value, risk, governance, finance and lifecycle decision-making.

-

On the right-hand side, the Maintenance perspective, focusing on performance, reliability, methods and execution.

These two sides continuously interact; strategy and governance flow from left to right, while performance feedback flows from right to left.

To translate this dynamic relationship into a practical structure for designing an AMS, the model is expressed as a six-layer pyramid:

-

Systems

-

Sub‑systems

-

Function and Aspect Systems

-

Processes

-

Functions

-

Items

The lemniscate defines the interaction, and the six-layer pyramid provides the structure from the organizational context down to the individual managed items.

Together, they deliver the vertical line of sight described in ISO 55000:2024, ensuring that every decision and action—no matter how detailed—is explicitly linked back to the strategic objectives of the organization.

In the European context, this chapter makes specific reference to the standards produced by CEN/TC 319 (Maintenance).

This technical committee has published a family of standards that support professional maintenance and asset management.

The most relevant in this context are EN 13306 (terminology), EN 17007 (processes) and EN 17666 (maintenance approaches), but CEN/TC 319 also develops standards for topics such as documentation, key performance indicators, outsourcing and cost control.

Together, these standards create a comprehensive framework that complements the ISO 55000 series.

This framework is therefore used here as a blueprint for designing, setting up and continuously improving an AMS.

Why does this combined view lead to a complete AMS?

-

Clarity of scope: It avoids confusion between organizational context, governance, processes, functions and assets.

-

Integration: It connects Asset Management (left) and Maintenance (right) into a single system rather than two separate worlds.

-

Alignment: Processes (EN 17007) and functions (EN 17666) ensure that daily execution is fully aligned with long-term strategy and risk appetite.

-

Transparency: Every decision can be traced upward to organizational objectives and downward to the specific items that deliver value.

-

Compliance: It naturally aligns the AMS with ISO 55000:2024 and the CEN/TC 319 family of standards.

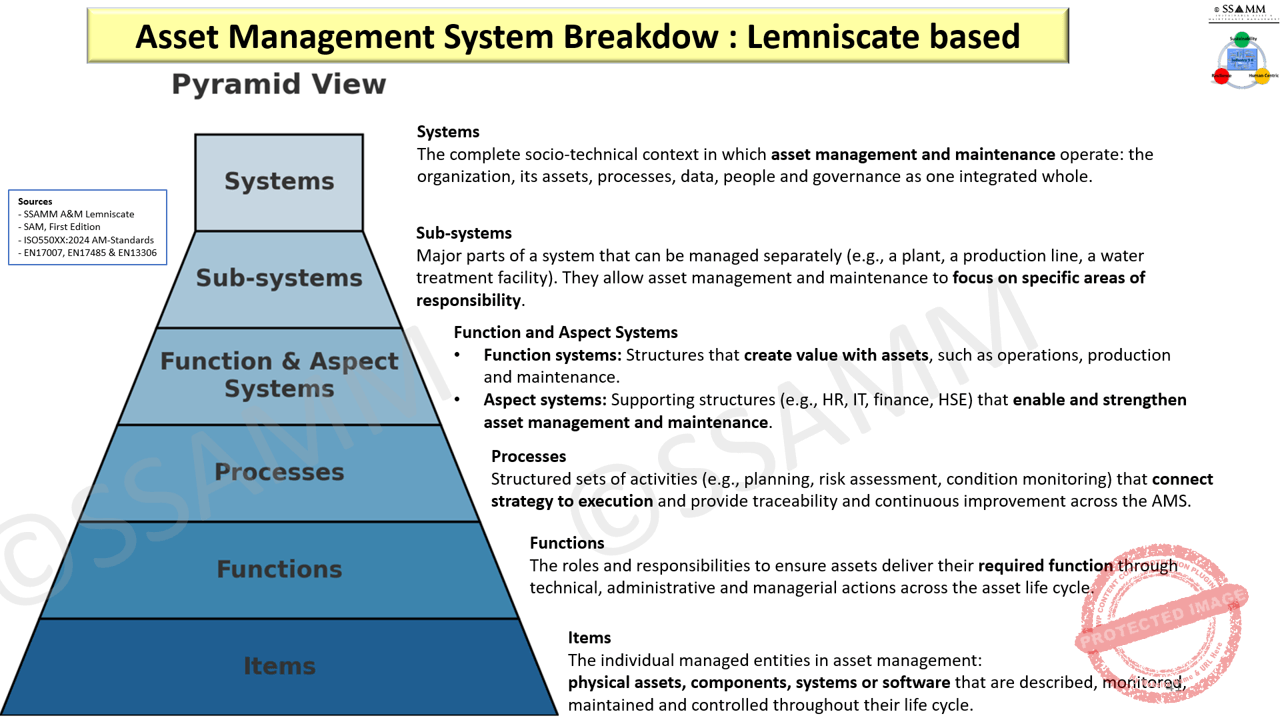

2.1 Systems

At the highest level, an AMS is a system within a broader organizational and societal context.

A system consists of people, assets, technology, processes and information, all interacting in a defined environment to achieve specific objectives.

Systems thinking ensures that all relevant elements and their interdependencies are considered, from long‑term governance and funding to safety, compliance and societal impact.

Examples of systems:

-

a national railway network

-

a water utility

-

an airport infrastructure

-

a large, integrated manufacturing enterprise

According to ISO/IEC/IEEE 15288, a system is:

A combination of interacting elements organized to achieve one or more stated purposes.

2.2 Sub-systems

A sub‑system is a smaller system that is part of a larger system (ISO/IEC/IEEE 15288).

Each sub‑system has a clear scope, set of objectives and a defined role within the larger structure.

Sub‑systems make it possible to divide complex organizations into manageable parts, enabling targeted governance, asset risk control and decision‑making.

Examples include:

-

Water utility: treatment plants, pumping stations and pipeline networks

-

Industrial site: production lines, power generation, logistics systems, ICT infrastructure

At this level, the perspective is primarily structural and object‑oriented.

We are defining “what exists” in the system, not yet how it is governed or supported.

2.3 Function Systems and Aspect Systems

From this point onwards, the focus shifts from what the parts are to what these parts do.

-

Function systems are the parts of the organization that directly contribute to primary value creation (production, operations, asset planning and maintenance).

-

Aspect systems are the supporting structures that enable the function systems to perform effectively, such as HR, IT, finance, safety, environmental management and quality assurance.

This distinction is crucial because many operational problems are not caused by the primary function systems, but by weaknesses in the supporting aspect systems.

For example, a production line may have excellent maintenance engineers but still suffer from disruptions caused by late spare parts delivery (procurement) or poor information systems.

2.4 Processes

Processes define how activities are organized, controlled, integrated and measured.

At this layer, the EN 17007 standard from CEN/TC 319 is the primary reference.

It describes the core maintenance processes and their interactions, including for example:

-

ACT (Asset configuration management)

-

BUD (Budgeting)

-

COR (Corrective actions)

-

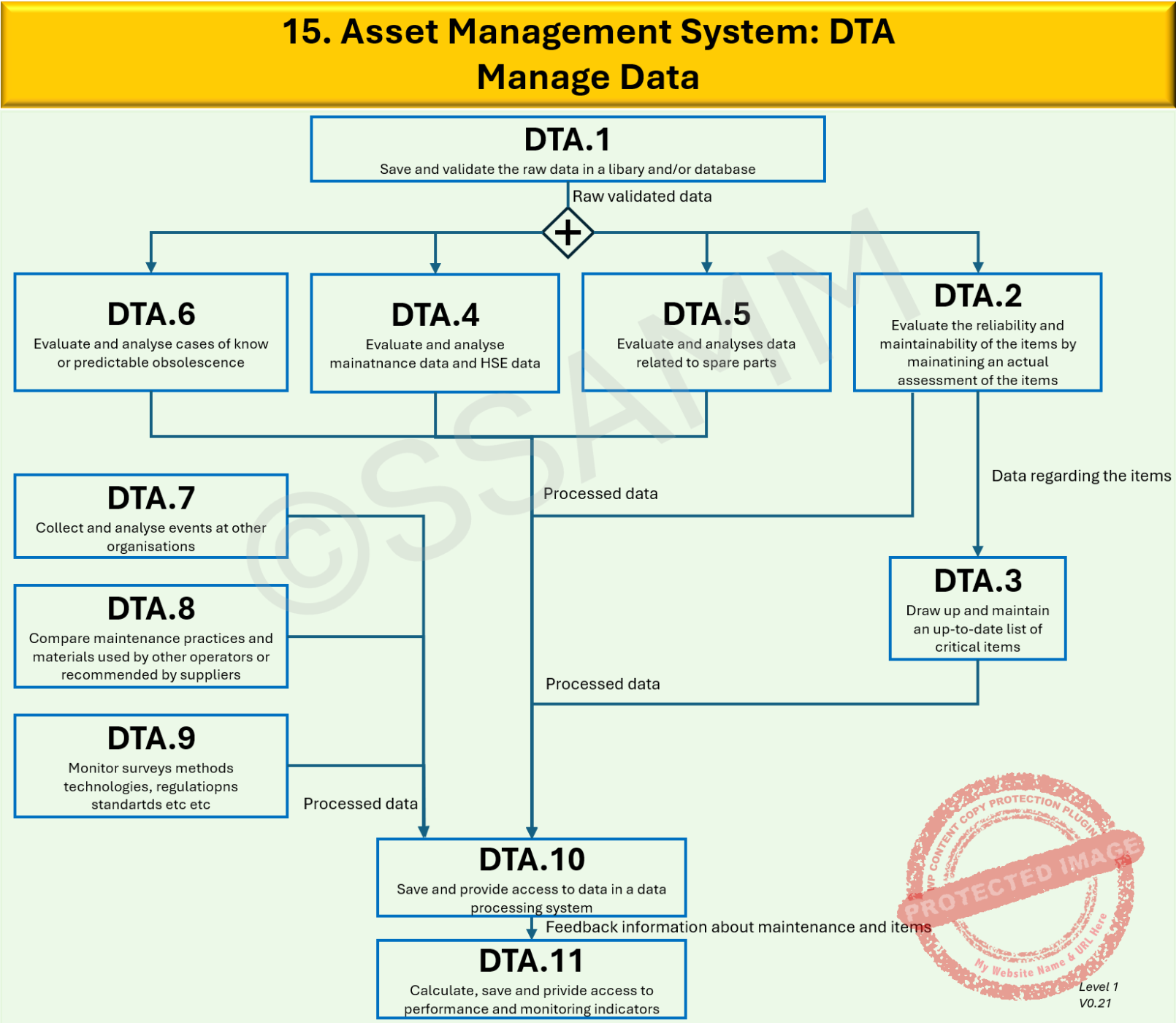

DTA (Data management)

-

OPT (Optimization)

-

PRV (Preventive actions)

-

SPP (Support processes)

and several others.

These processes ensure consistency, traceability and continuous improvement across the organization.

Processes act as the bridge between governance and execution, describing what needs to be done, regardless of which department or team performs the work.

Example:

Failure analysis, risk assessment, inspection planning, budgeting and reporting processes must be harmonized across different sub‑systems so that the whole organization operates as one coherent system.

2.5 Functions

This layer focuses on roles, responsibilities, accountabilities, competencies and decision rights.

It answers the key questions: “Who performs which tasks? Who makes which decisions? What expertise and capabilities are required?”

In the context of asset management, maintenance is a key organizational function.

According to EN 13306 (2.1):

The combination of all technical, administrative and managerial actions during the life cycle of an item intended to retain it in, or restore it to, a state in which it can perform the required function.

The required function of an asset is defined in EN 13306 (2.6) as:

The function, combination of functions, or total combination of functions of an item which are considered necessary to fulfil a given requirement.

In addition, EN 17666 (Maintenance – Maintenance approaches), another CEN/TC 319 standard, is referenced at this layer.

It classifies and describes different maintenance approaches and methodologies such as:

-

Corrective maintenance

-

Preventive maintenance

-

Condition-based maintenance

-

Predictive maintenance

-

Risk-based maintenance

-

Reliability-Centered Maintenance (RCM)

-

Total Productive Maintenance (TPM)

This enables the organization to define which methods are applied and how they are aligned with the strategic goals and risk appetite.

Thus, the function layer connects organizational structure, competencies, and chosen maintenance strategies.

2.6 Items

At the lowest level are the specific managed entities of the AMS – the assets and components that are individually described, monitored and controlled.

EN 13306 (3.1) defines an item as:

A part, component, device, subsystem, functional unit, equipment or system that can be individually described and considered.

Items can include:

-

Physical assets (machines, components, instruments)

-

Sub‑systems or even entire systems

-

Software (programs, data, rules and documentation)

-

Populations of similar assets treated as one managed group

Difference from elements:

-

All items are elements.

-

Only those elements that are explicitly managed as individual units, with recorded data, maintenance actions and decisions throughout their life cycle, are considered items.

2.7 Why these six layers matter

The SSAMM A&MM Breakdown Lemniscate:

-

Establishes traceability from high‑level strategic objectives down to individual asset activities

-

Provides a clear and auditable structure for designing, implementing and improving an AMS

-

Aligns with ISO 55000 and the CEN/TC 319 family of standards (EN 13306, EN 17007, EN 17666)

-

Clarifies how assets, processes, roles and supporting systems interact to deliver value

This layered structure makes the AMS transparent, integrated, future‑proof and ready for continuous improvement.

3. Maintenance Process Breakdown

The integration of maintenance into the broader Asset Management System (AMS) requires a thorough understanding of the maintenance processes that serve as the operational backbone of physical asset management. While the AMS provides the overarching structure for policy, strategy, and decision-making, the maintenance process represents the essential execution mechanism through which asset performance, reliability, availability, and safety are realized and sustained.

In this context, the European Standard EN 17007:2017 Maintenance — Maintenance process and associated indicators offers a scientifically grounded and systematically structured process architecture. This standard introduces a universal maintenance process model that classifies, organizes, and connects all maintenance activities with corresponding performance indicators to drive continuous improvement. Whereas previous standards primarily offered definitions and conceptual guidance (such as EN 13306), EN 17007 establishes the operational foundation for process control and integrated governance of maintenance within the AMS.

Moreover, this process-oriented approach forms a core element within the Maintenance Landscape Model, where EN 17007 — in conjunction with the broader set of CEN/TC 319 maintenance standards — provides the methodological structure for maintenance engineering, management, and execution within physical asset management. This allows maintenance to be directly linked to both strategic policy objectives and day-to-day operational activities, fully aligned with the requirements of ISO 55001:2024 and the integrated management models articulated in ISO 55002, ISO 55010, ISO 55012, and ISO 55013.

In the following sections, the maintenance process as structured in EN 17007 will be systematically explained, providing a comprehensive understanding of how maintenance processes can be organized, governed, measured, and continuously improved as an integral component of the broader asset management system.

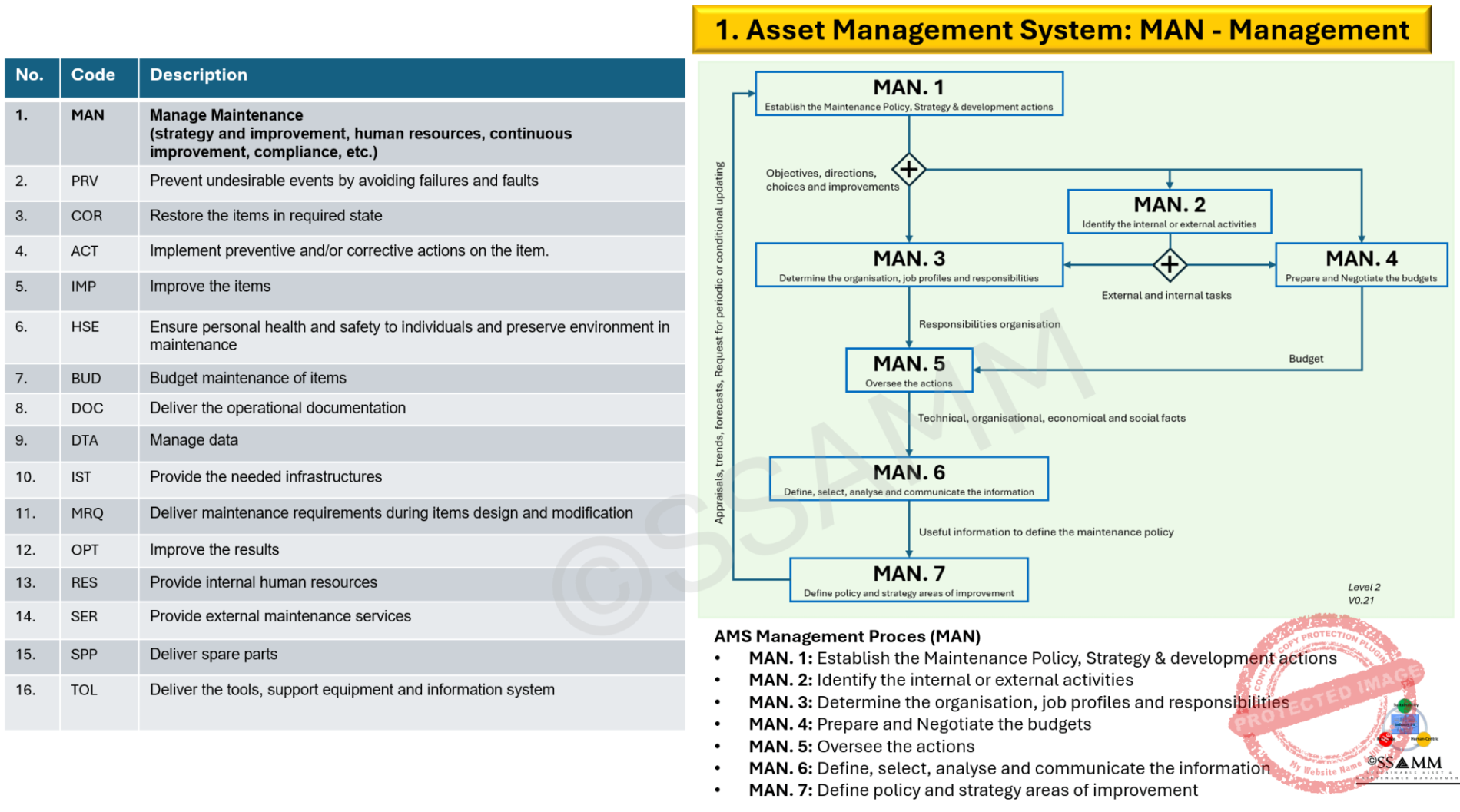

3.1 Introduction to Maintenance Process Breakdown

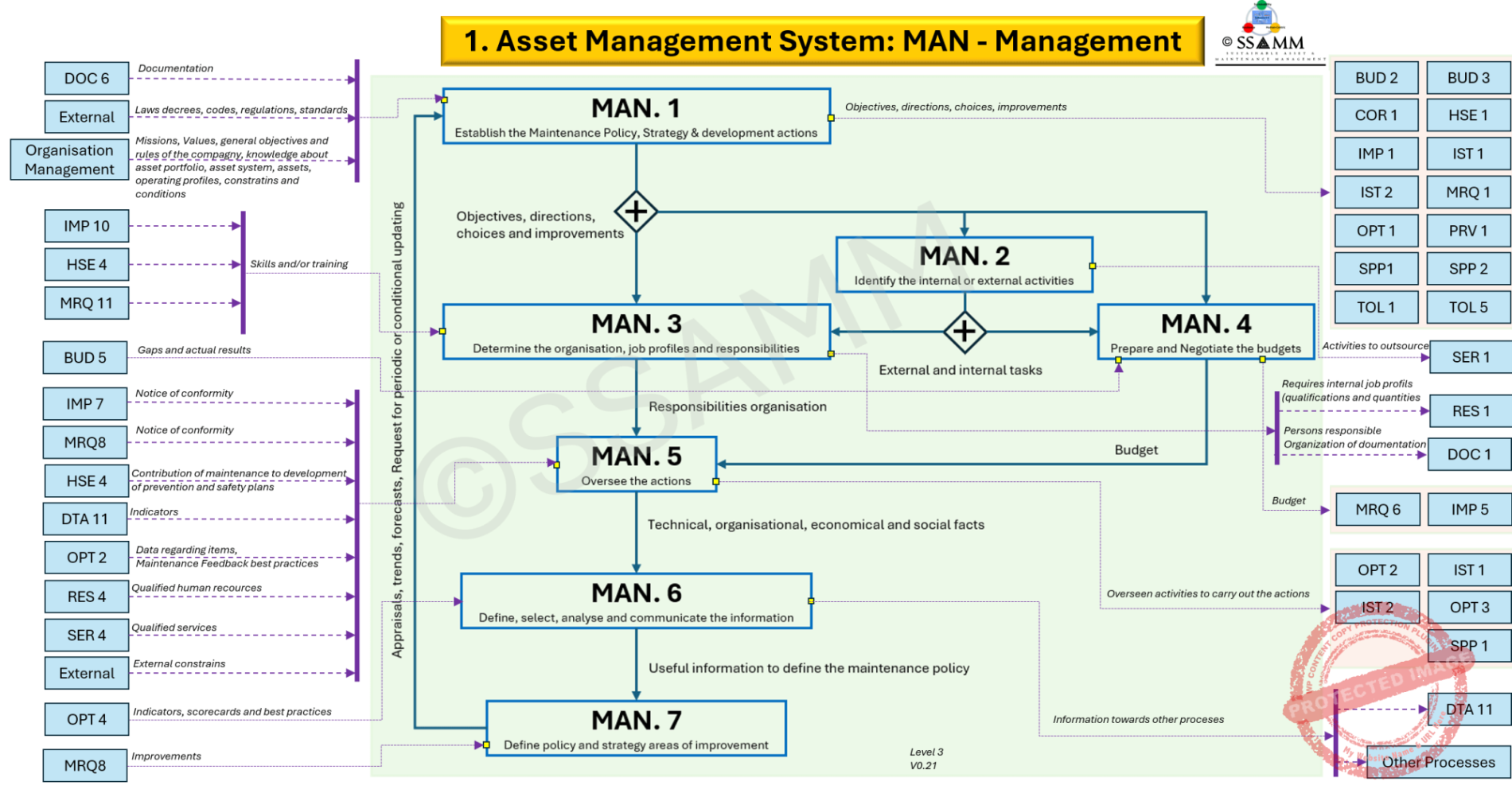

The maintenance process (Figure 4), as detailed in the European Standard EN17007, provides a structured approach for identifying, classifying, and systematically managing maintenance activities. It outlines three primary process families—Management processes, Realization processes, and Support processes—each essential for a coherent and effective maintenance strategy. By following the standardized maintenance process breakdown, organizations can effectively streamline maintenance management, improve reliability, and align maintenance activities with organizational goals.

Fig. 4: The Maintenanec Process. Click to enlarge

Implementing this structured approach helps organizations maintain clear visibility over maintenance activities, promotes efficient resource allocation, and improves decision-making clarity at all management levels. It further assists in creating a cohesive maintenance culture and encourages accountability and responsibility throughout the organizational structure.

3.2 Maintenance Process Families

EN17007 categorizes maintenance processes into three key families, each with distinct roles and responsibilities that collectively ensure a holistic approach to asset management:

- Management Process: This family includes activities focused on setting strategic objectives, formulating maintenance policies, deploying necessary resources, and coordinating various processes. It emphasizes continuous performance measurement, monitoring, analysis, and subsequent improvements, ensuring that maintenance operations align closely with overall organizational strategies. Additionally, it addresses the alignment of maintenance processes with regulatory compliance and organizational risk management.

- Realization Processes: Realization processes directly influence the maintenance outcomes and customer satisfaction by addressing the core maintenance activities. This family involves preventive maintenance to avoid failures, corrective actions to restore functionality, performance improvement initiatives, and strategic interventions that optimize asset conditions, reliability, and lifecycle value. Realization processes are directly accountable for the delivery of reliable, effective, and compliant maintenance services to the organization and its stakeholders.

- Support Processes: These processes provide critical resources and support essential for the smooth operation and success of management and realization processes. Support processes include human resource management, financial planning, material and infrastructural maintenance, comprehensive documentation, information system management, external service provision, and spare parts logistics, thereby enabling effective execution of maintenance activities. This support ensures operational continuity and resource availability.

3.3 Detailed Breakdown of Maintenance Processes

EN17007 presents a detailed and structured breakdown, categorizing maintenance processes into hierarchical levels to enhance clarity and operational efficiency:

- Level 1: Provides an overall conceptual mapping, clearly delineating the major maintenance processes and classifying them into management, realization, and support categories. This overarching view facilitates strategic oversight and high-level integration of maintenance activities with organizational objectives.

- Level 2: Further refines Level 1 processes into specific and actionable sub-processes, clearly identifying inputs, outputs, critical activities, interfaces, and stakeholder responsibilities. This detailed breakdown enables targeted execution and facilitates clear accountability and process governance.

- Level 3: Offers detailed, task-level descriptions within each Level 2 sub-process. Although not explicitly detailed in the EN17007 standard due to its variability across organizations, Level 3 is crucial for operational clarity, practical execution, and daily management of maintenance activities. Organizations tailor this level to their specific operational contexts and maintenance strategies.

Each Level 2 process profile explicitly includes its intended purpose, detailed activities, clearly defined inputs and outputs, stakeholder roles and responsibilities, constraints, and relevant performance indicators. These elements ensure comprehensive process clarity and facilitate effective management and continuous improvement.

3.4 Practical Implementation and Organizational Advantages

Organizations employing the structured breakdown of maintenance processes detailed in EN17007 can realize several significant operational and strategic advantages, including:

- Clearly defined and systematically managed processes with unambiguous roles, responsibilities, and performance criteria.

- Enhanced organizational clarity and recognition of maintenance’s strategic role, thereby improving communication, accountability, and stakeholder engagement.

- Improved clarity regarding objectives, facilitating quantifiable and consistent measurement of process performance and efficiency.

- Facilitated proactive management through effective monitoring and early detection of deviations from established targets or standards.

- Effective training, knowledge management, and capability development through structured documentation and standardized processes.

- Enhanced continuous improvement culture, supported by regular performance assessments, feedback loops, and corrective actions.

- Integrated and cohesive support for organizational Information Systems, thereby improving data-driven decision-making and operational transparency.

3.5 Specific Maintenance Processes

According to EN17007, detailed maintenance processes include specific activities within each main family:

- Management Processes:

- MAN: Maintenance strategy formulation, resource allocation, compliance management, performance monitoring, continuous improvement.

- Realization Processes:

- PRV: Proactive prevention of undesirable events to ensure reliability.

- COR: Restoration of asset functionality and condition following failures.

- ACT: Implementation of both preventive and corrective actions.

- IMP: Strategic initiatives to continuously enhance asset performance and reliability.

- Support Processes:

- HSE: Maintenance-related health, safety, and environmental management.

- BUD: Effective financial planning and budgeting for maintenance activities.

- DOC: Management and provision of comprehensive operational documentation.

- DTA: Systematic maintenance data management and utilization.

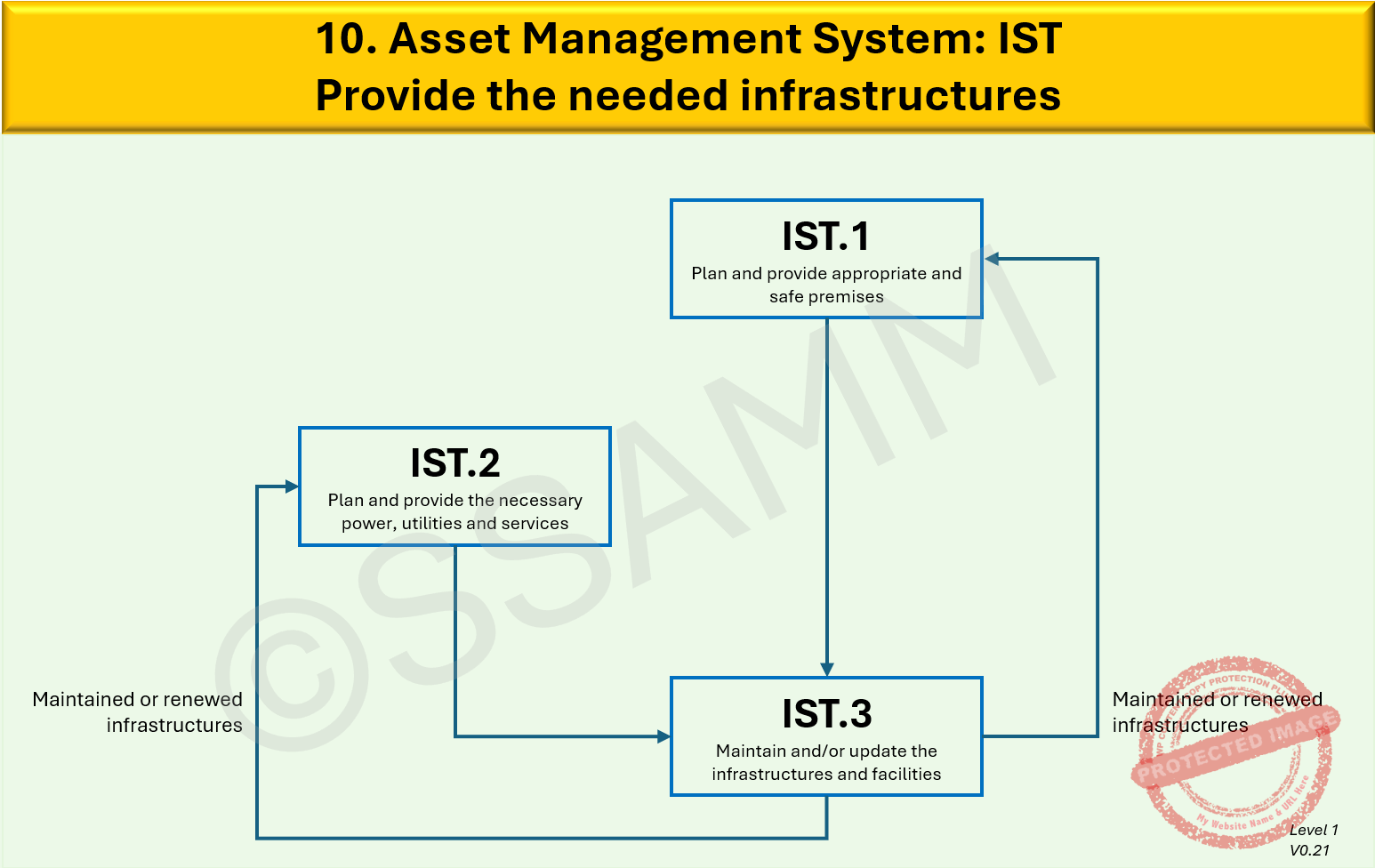

- IST: Provision and management of essential infrastructure.

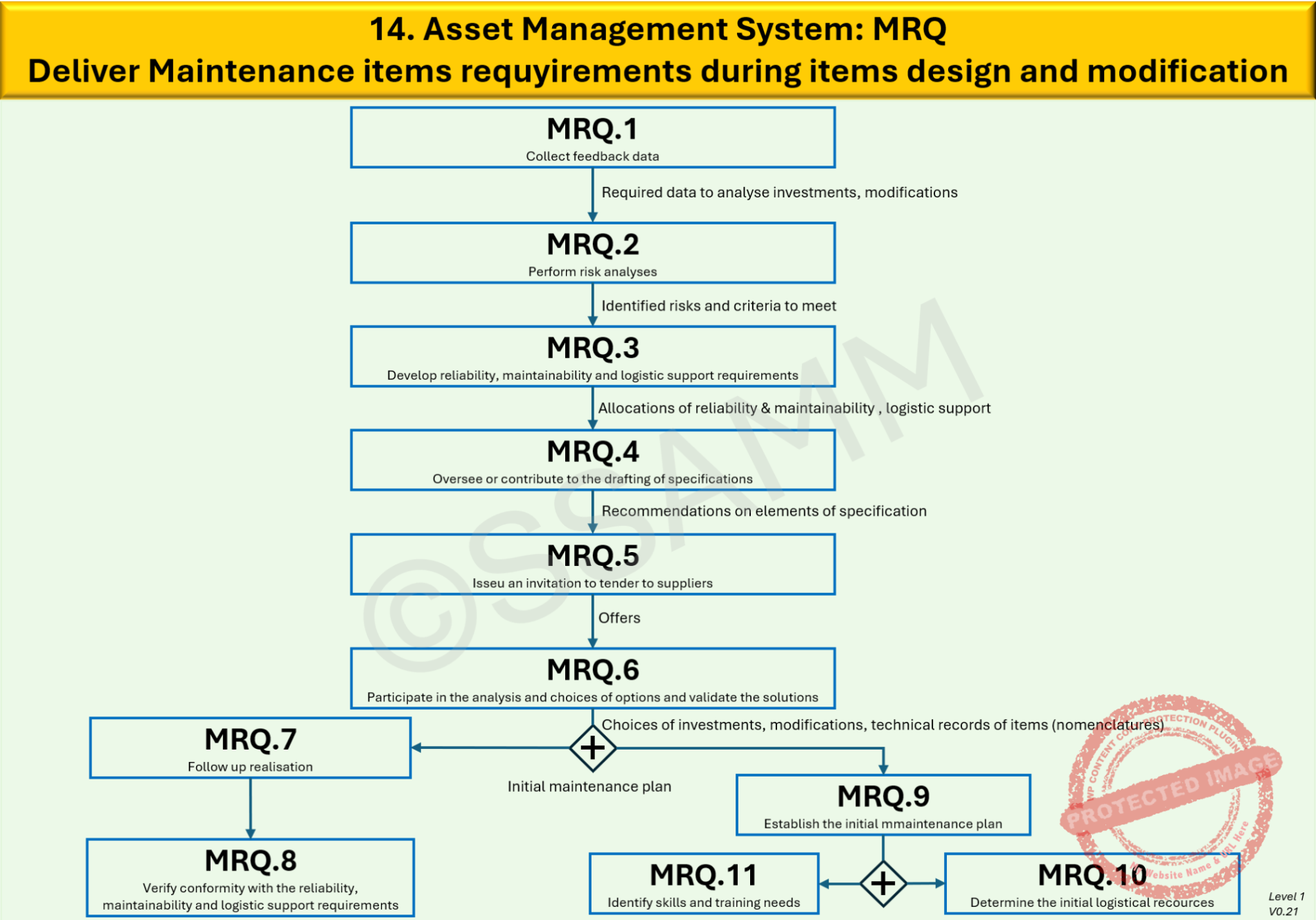

- MRQ: Incorporation of maintenance requirements into asset design and modifications.

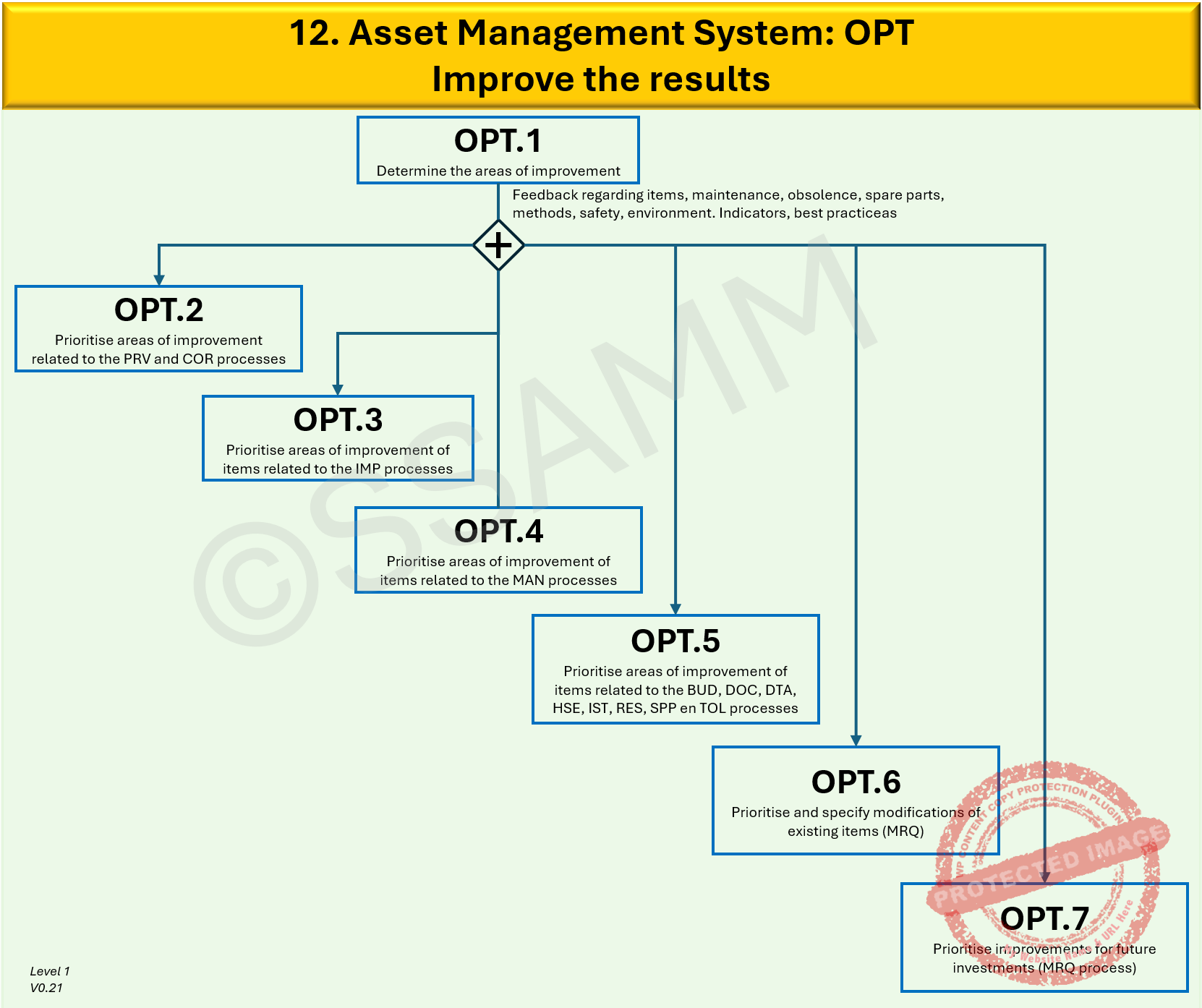

- OPT: Continuous optimization of maintenance outcomes.

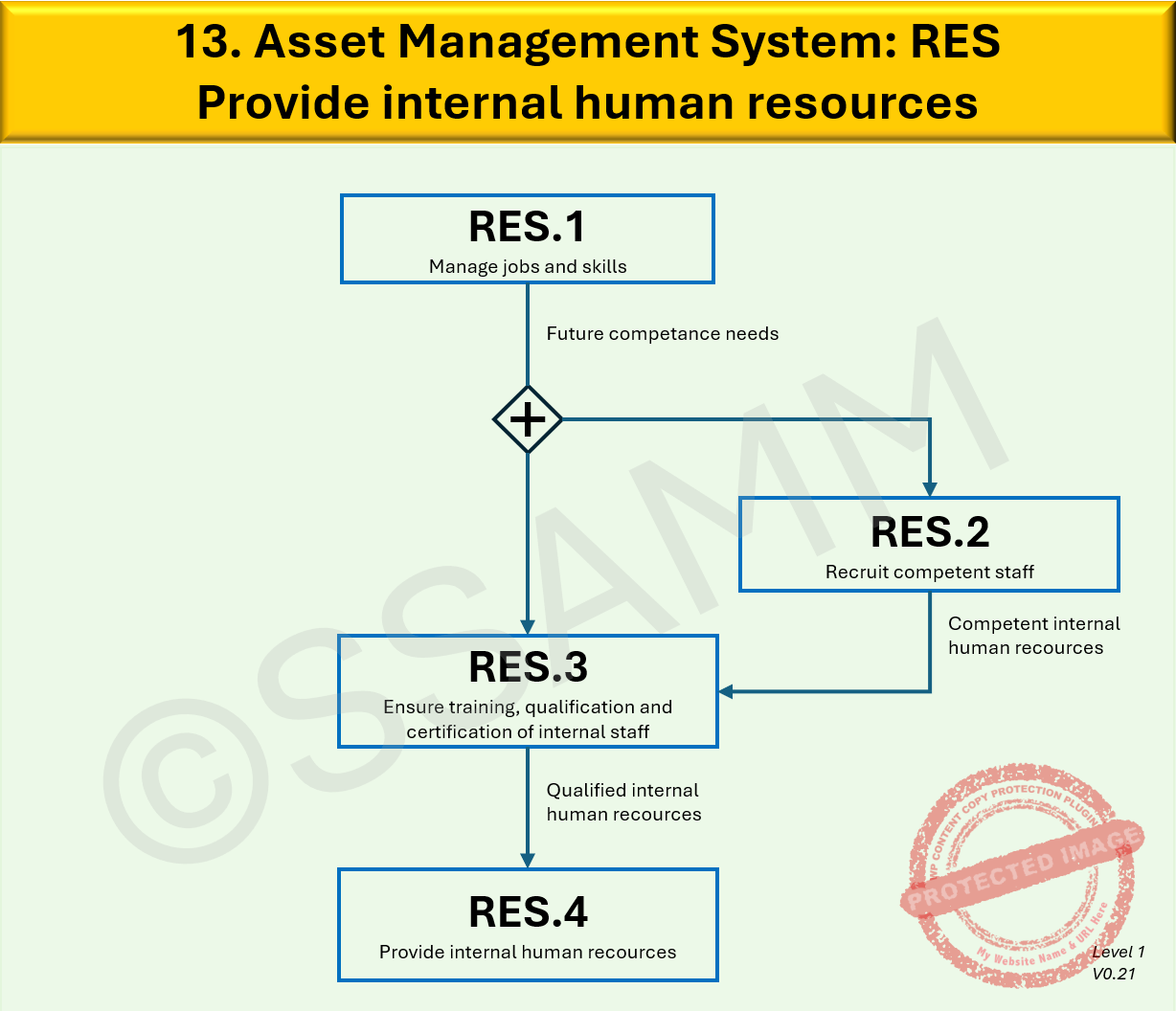

- RES: Efficient management of internal human resources.

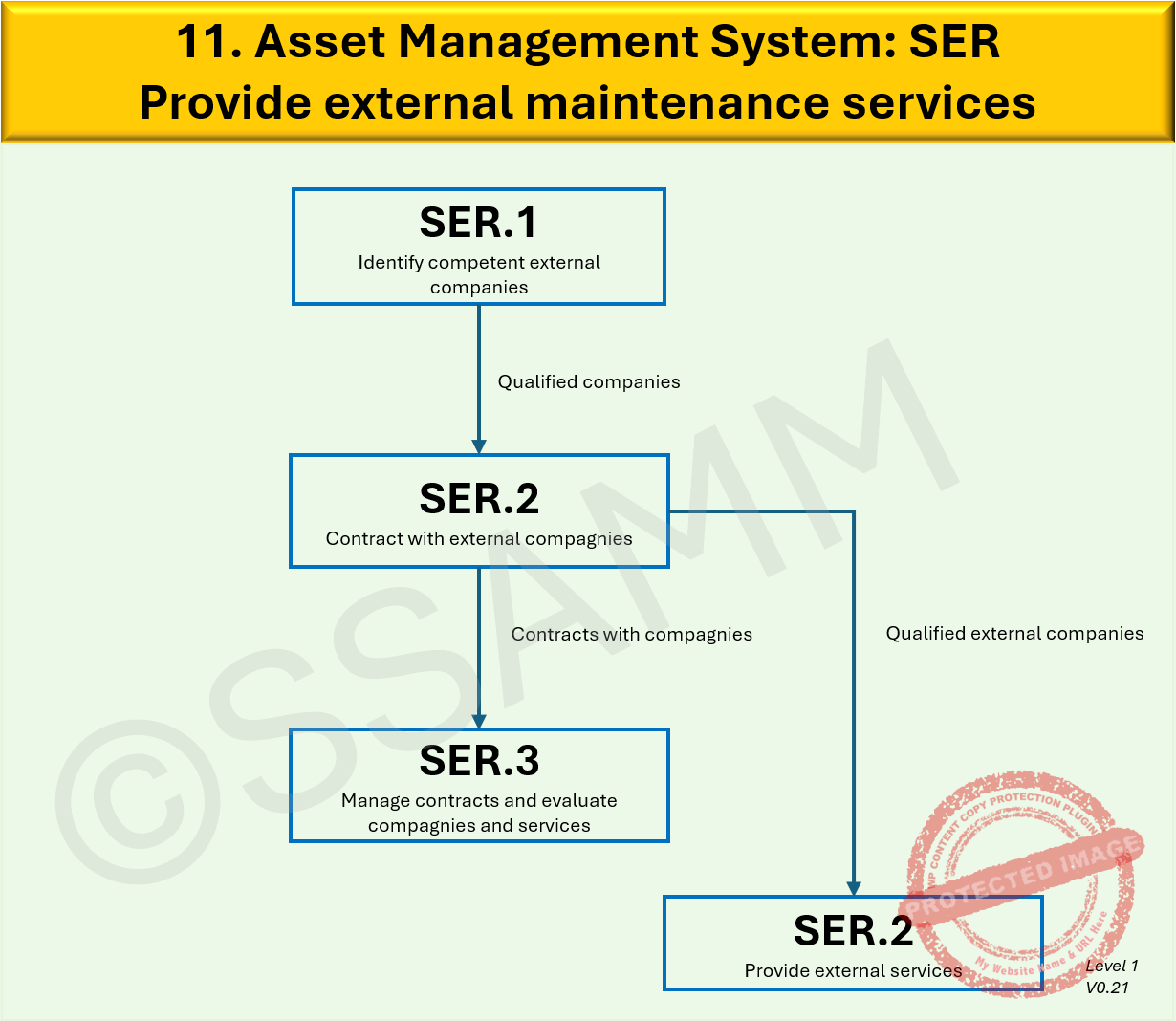

- SER: Effective management of external maintenance service providers.

- SPP: Efficient logistics management of spare parts.

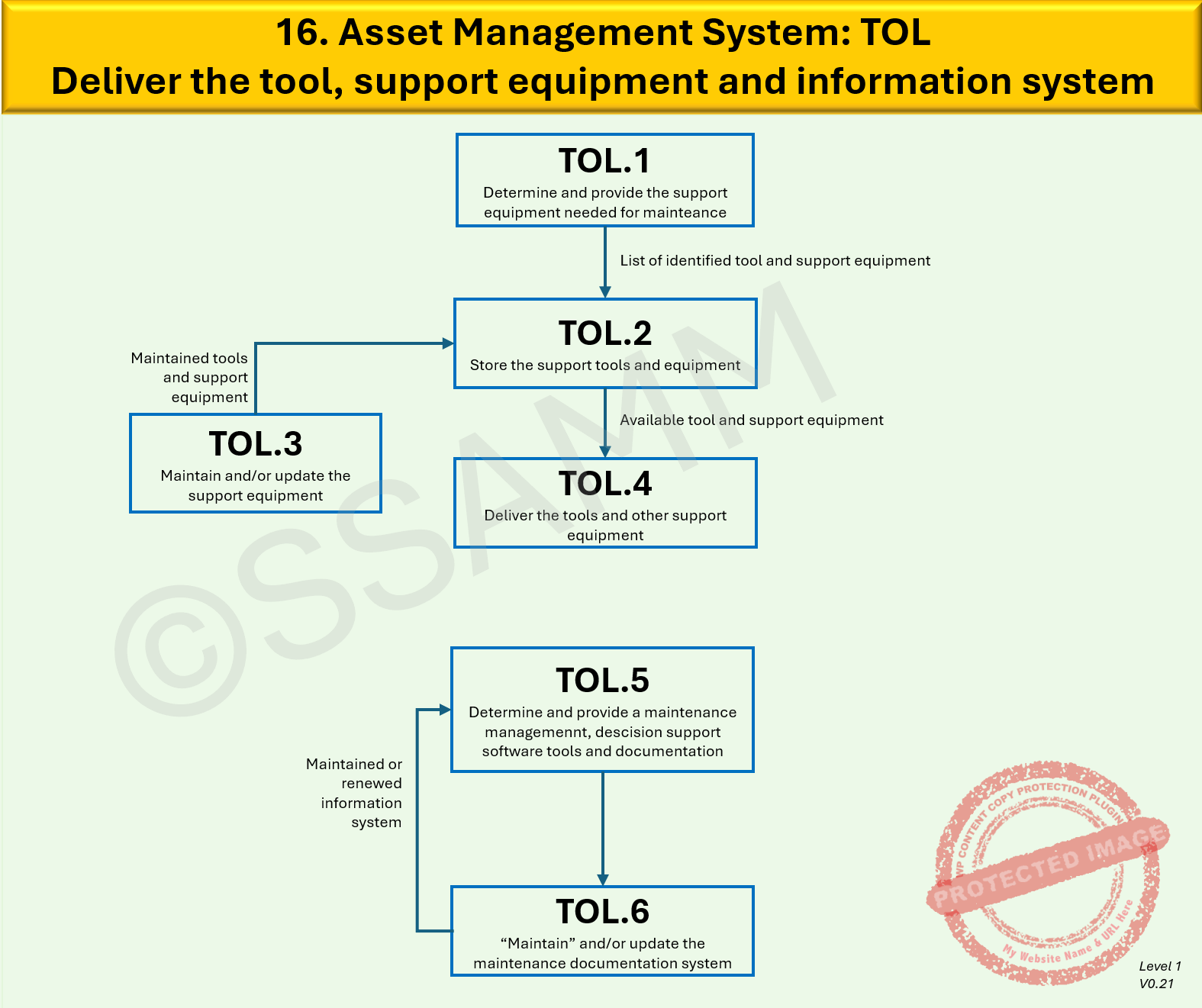

- TOL: Management of tools, equipment, and information systems required for maintenance.

3.6 Indicators and Continuous Improvement

Organizations must define specific, relevant indicators for each maintenance process to systematically monitor performance, evaluate effectiveness, and ensure alignment with strategic objectives. Regular collection, analysis, and dissemination of these indicators enable continuous evaluation and improvement of maintenance practices, fostering a proactive culture of excellence. These indicators serve as essential tools for internal benchmarking, performance management, and strategic decision-making, ultimately enhancing overall asset management effectiveness and ensuring long-term organizational sustainability.

4. Detailed Explanation of Maintenance Processes

4.1 Management Process

4.1.1 The MAN-1 process: Manage Maintenance

The Management Process (MAN), as described in EN17007, represents a critical strategic component within the Asset Management System framework. It fundamentally guides and governs all maintenance-related decisions and actions, aligning them with the company’s broader objectives and operational strategy. This alignment is crucial to achieving not only optimal asset performance but also to ensuring regulatory compliance, safety, environmental protection, and economic efficiency.

The management process serves as the backbone of AMS by establishing clear policy guidelines and maintenance strategies. The key objective of the management process is to systematically direct maintenance activities to fulfill organizational objectives, maximize asset reliability, and ensure sustainable operational performance.

Key activities within the Management Process (MAN) include:

- MAN.1 – Establish the Maintenance Policy, Strategy, and Development Actions: This foundational step involves defining clear directions based on the company’s mission, values, regulatory compliance, and general objectives. Priorities such as safety, asset availability, environmental responsibility, and cost optimization form the basis of the strategic decisions made here. It encompasses the development and implementation of maintenance methods, resource organization, and economic evaluations.

- MAN.2 – Identify Internal or External Activities: Clear delineation between internally performed tasks and those contracted externally ensures effective resource utilization, informed budgeting decisions, and adequate skill allocation. This process supports strategic choices between insourcing and outsourcing maintenance activities.

- MAN.3 – Determine Organization, Job Profiles, and Responsibilities: Based on strategic guidelines, an organizational structure is established to effectively execute maintenance tasks. Job profiles, roles, responsibilities, and necessary skills are clearly defined, promoting clarity, accountability, and effective human resource management.

- MAN.4 – Prepare and Negotiate Budgets: Budgets are carefully prepared, aligned with strategic maintenance goals, and regularly reviewed and approved by management. Budgeting processes ensure that financial resources are optimally allocated and managed efficiently.

- MAN.5 – Oversee Actions: Coordination and supervision of all maintenance-related actions guarantee alignment with strategic goals and compliance with safety, environmental, quality, and cost objectives. This supervisory role ensures responsiveness to dynamic operational conditions.

- MAN.6 – Define, Select, Analyze, and Communicate Information: This activity involves managing the critical flow of technical, organizational, economic, and social information. Effective communication internally and externally ensures transparency, facilitates informed decision-making, and promotes stakeholder engagement.

- MAN.7 – Define Policy and Strategy Areas of Improvement: Continuous analysis of information enables the refinement and improvement of maintenance policies and strategies. It ensures the organization’s adaptive capacity to changing environments, improving strategic agility, and operational effectiveness.

The management process integrates various inputs, such as company objectives, regulatory requirements, external constraints, budget data, and performance indicators. Outputs generated include maintenance policies, strategies, budgets, roles, and responsibilities clearly articulated to guide operational execution. Regular monitoring and assessment through defined indicators ensure ongoing alignment with organizational objectives and continual improvement.

By embedding these structured management processes within the AMS framework, organizations ensure a strategic approach to maintenance, improving operational reliability, reducing lifecycle costs, and achieving sustained organizational resilience and excellence.

4.2 Realization Process

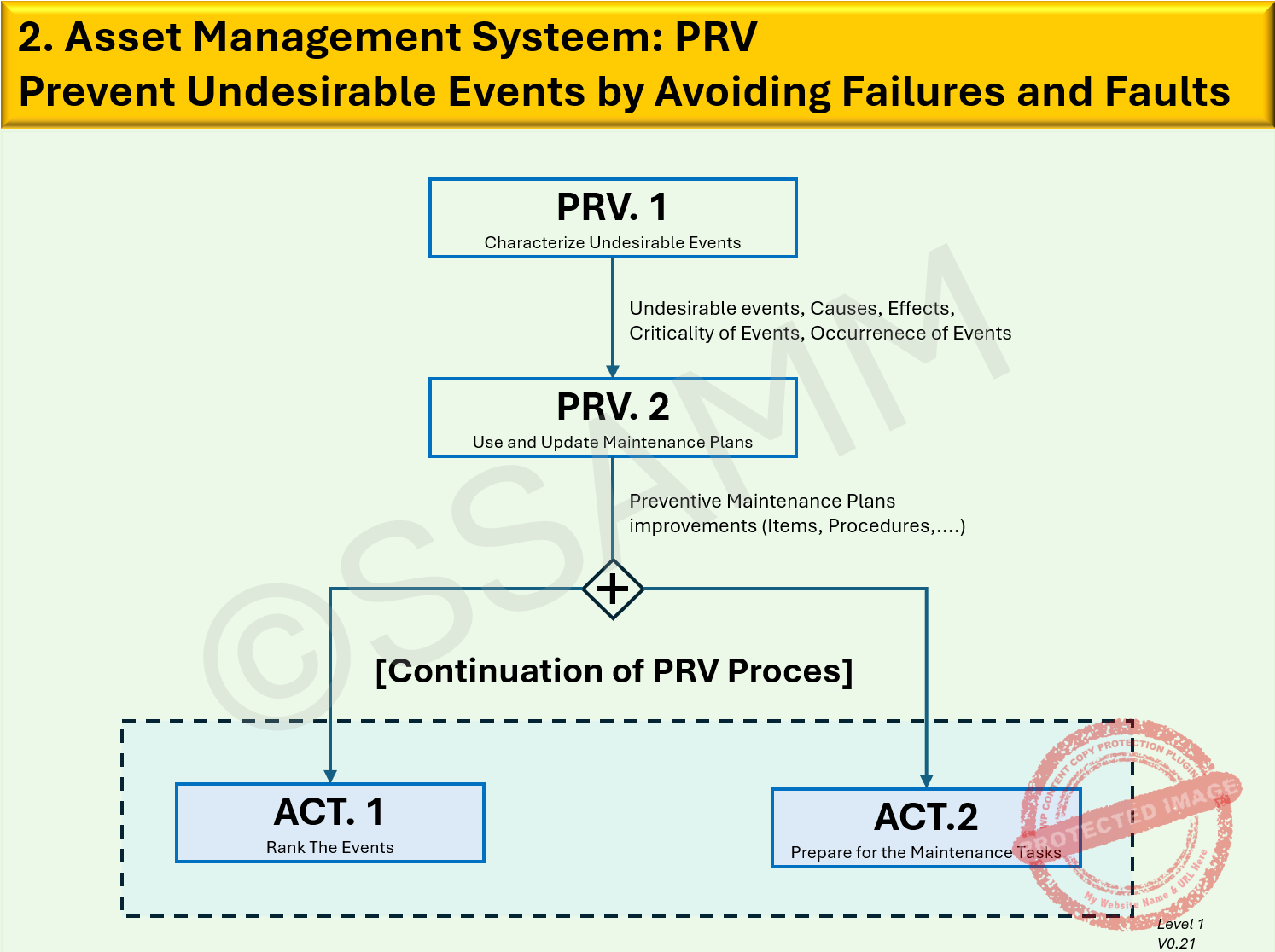

4.2.1 The PRV-2 rocess: Prevent Undesirable Events

The PRV process is divided into two core sub-processes: PRV.1 and PRV.2. Together, they form a coherent and systematic approach to analyzing, prioritizing, and planning preventive maintenance actions. These activities are tightly linked to strategic directions defined under the management process (MAN) and are supported by documentation, data management, and historical records.

PRV.1 – Characterize the Undesirable Events

The objective of PRV.1 is to systematically identify, classify, and prioritize potential or historical events that may lead to asset degradation or failure. These events are analyzed for their potential impact on business-critical factors such as safety, availability, cost, product or service quality, and environmental compliance.

Key activities include:

- Compiling a comprehensive list of known or potential failure events and evaluating their impact across technical, economic, and operational dimensions.

- Identifying causal chains and failure modes associated with these events.

- Analyzing whether these failure modes are observable or latent (hidden from the user or operator).

- Prioritizing events based on frequency, severity, and impact to establish which require immediate preventive attention.

- Selecting suitable methodologies for the detection and monitoring of hidden faults.

The outputs of PRV.1—documented events, causal chains, and their criticality—inform multiple other maintenance and asset management processes, particularly in determining risk-informed interventions and updates to preventive strategies.

PRV.2 – Use and Update the Maintenance Plans

Building upon the findings of PRV.1, PRV.2 defines the preventive maintenance actions required to mitigate identified risks and sustain asset performance. This process is designed to ensure that preventive measures are technically appropriate, economically justifiable, and organizationally feasible.

Key activities include:

- Developing and revising condition-based or time-based maintenance tasks in accordance with risk profiles.

- Integrating item and procedural improvements aimed at reducing the occurrence and impact of undesirable events.

- Reviewing and revising operating procedures to align with updated failure mode understanding.

- Designing protective strategies against potential consequences of identified events.

- Formalizing maintenance plans that specify tasks, intervals, required resources, and responsibilities.

PRV.2 ensures that maintenance planning remains a dynamic and iterative process. It accommodates new data, evolving asset conditions, and shifting operational demands. The maintenance plan thus becomes a living document that evolves in sync with both technical insights and organizational strategy.

Both PRV.1 and PRV.2 require strong interfaces with supporting processes, including documentation (DOC.6), optimization (OPT.2), and maintenance requirements (MRQ.9). They rely heavily on high-quality data, historical records, and well-maintained asset documentation. As such, they benefit significantly from robust information systems and continuous collaboration between asset stakeholders.

Indicators linked to the PRV process include the number of identified undesirable events, their criticality, coverage of equipment by maintenance plans, the frequency of plan revisions, and the effectiveness of preventive actions in avoiding undetected failures.

Together, PRV.1 and PRV.2 demonstrate how EN17007’s realization processes serve as the operational backbone of the AMS. They translate risk-based thinking into structured, measurable preventive strategies—thus reinforcing the system’s ability to achieve the objectives outlined in ISO 55000:2024 and maintain the long-term integrity, safety, and value of physical assets.

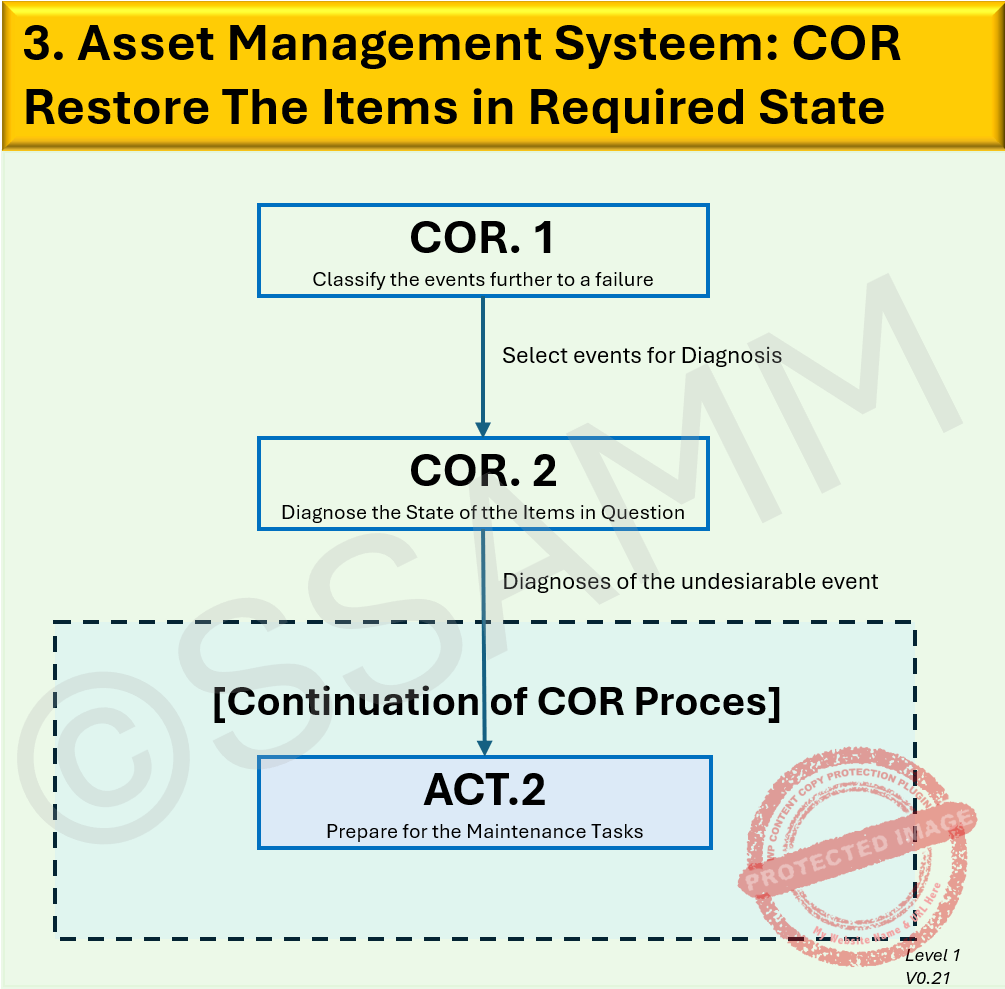

4.2.2 The COR-3 process: Restoring Items to Their Required State

COR.1 – Prioritize and Schedule Corrective Events This sub-process begins with the identification and classification of actual events that necessitate immediate or near-term corrective actions. Events are assessed based on severity, operational and environmental constraints, and availability of resources. A ranked list is produced to ensure critical failures are prioritized. A preliminary scheduling is then developed to coordinate fault response within maintenance planning horizons.

COR.2 – Diagnose Root Causes and Degradation Mechanisms Once priority events are selected, fault diagnosis is performed. This step involves identifying the affected item and contextual conditions, tracing symptoms, locating failure points, and mapping degradation mechanisms. Emphasis is placed on identifying root causes through methods such as Root Cause Analysis (RCA), Failure Mode and Effects Analysis (FMEA), or Fault Tree Analysis (FTA). Lessons learned during this phase guide future preventive strategies.

Input Data

- Detected undesirable events (ACT.1)

- Operational and environmental constraints

- Manufacturer and engineering documentation

- Maintenance history and records (OPT.2)

- General and technical documentation (DOC.6)

Output Data

- Ranked list of events requiring correction

- Time-scheduled corrective actions

- Diagnosis of root causes and failure modes

- Recommendations for item or procedure improvement

Stakeholders This process involves maintenance engineers, reliability specialists, and operations staff. The “realizing party” is typically the corrective maintenance team; the “customer” of the process includes the asset owner and operations management.

Process Interfaces

- ACT.1 – Event detection and initiation of fault response

- ACT.2 – Maintenance scheduling

- DOC.6 – Access to technical files and documentation

- MAN.1 – Strategic alignment and operational constraints

- OPT.2 and OPT.3 – Feedback loop for learning and improvement

- Operation – Ensuring coordination with production systems

Constraints

- High risk due to presence of energy or hazardous conditions

- Diagnostic complexity requiring specialized knowledge

Performance Indicators

- (i1cor1) Number of actual events processed within planning period

- (i2cor1) Criteria validity for event prioritization

- (i1cor2) Mean fault diagnosis time

- (i2cor2) Ratio of repetitive failures without root cause resolution

- (i3cor2) Incidence of unnecessary work orders

- (i4cor2) Execution of root cause analysis for major failures

Observations Corrective maintenance often carries operational urgency. The COR process ensures structured response through prioritization and professional diagnosis, enabling swift restoration and long-term improvement. By identifying systemic failure patterns, the process serves as a catalyst for reliability improvement and operational resilience.

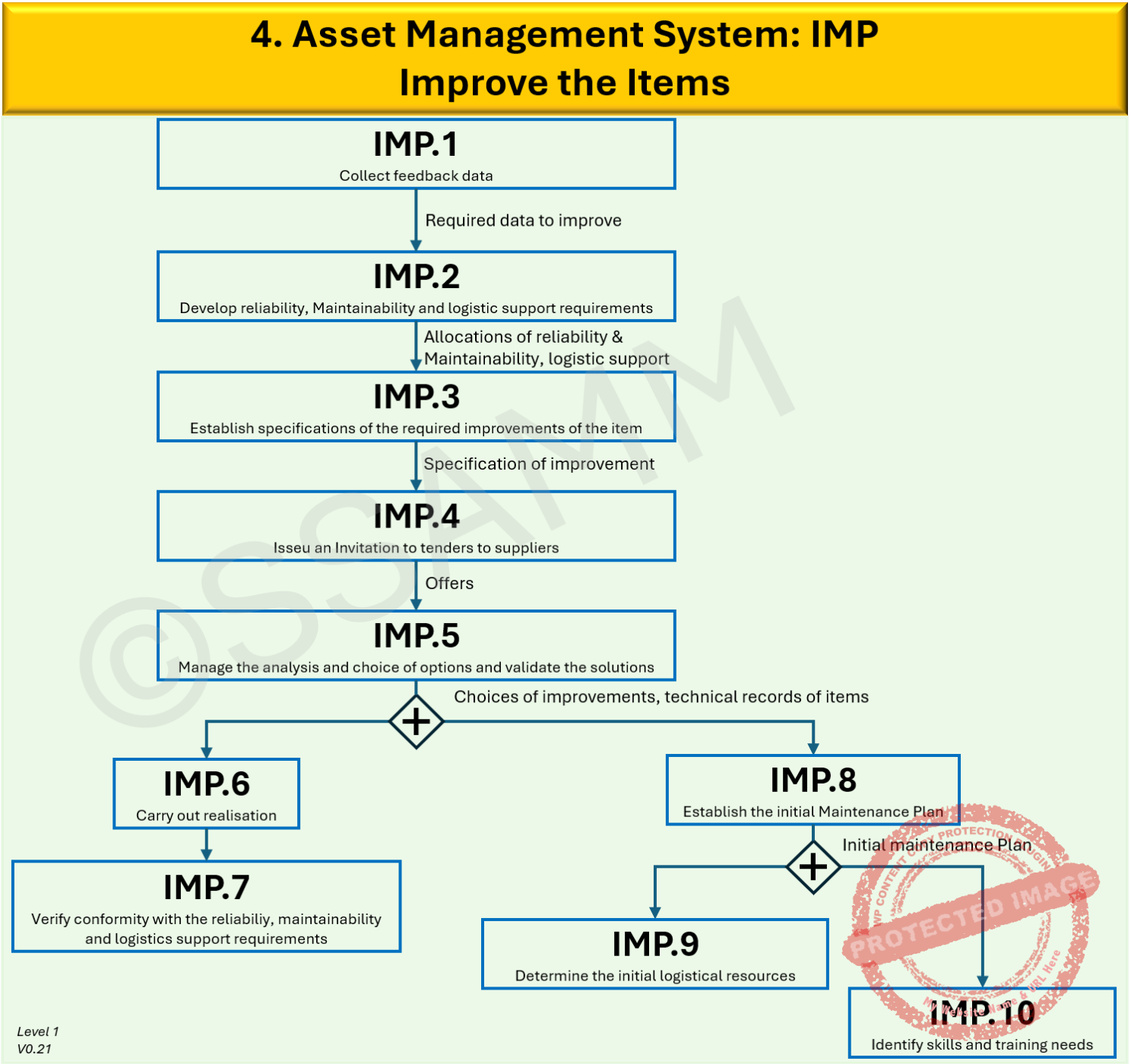

4.2.3 The IMP-4 process: Improve the Items

The IMP process is structured into ten interrelated sub-processes that together form a comprehensive framework for asset enhancement. It begins with data collection and requirement definition and ends with the deployment of initial logistical support, updated maintenance plans, and appropriate skills development. These sub-processes are essential for creating an optimized maintenance environment and facilitating informed decision-making throughout the asset lifecycle.

IMP.1 – Collect Data The process begins by gathering critical information required to evaluate potential improvements. This includes operational feedback, processed asset data, failure analyses, and historical maintenance information. The collected data serves as the empirical basis for identifying potential enhancements that align with organizational objectives and asset performance indicators.

IMP.2 – Define Reliability, Maintainability, Safety, and Logistic Support Requirements Using insights from both preventive and corrective experiences, specific targets for reliability, maintainability, safety, and supportability are developed. These metrics ensure that any proposed item improvements are aligned with long-term operational and performance goals, forming the backbone of subsequent specification activities.

IMP.3 – Establish Specifications for the Required Improvements Detailed technical specifications are defined, incorporating acceptance limits, evaluation criteria, and levels of design flexibility. These specifications ensure that item upgrades are clearly scoped and measurable against pre-established success parameters.

IMP.4 – Issue an Invitation to Tender The prepared specifications are integrated into tender documents distributed to internal or external suppliers. These documents outline expected performance outcomes and include all relevant criteria necessary for suppliers to propose viable solutions.

IMP.5 – Analyse and Choose Options and Validate the Solutions Proposals are critically reviewed by stakeholders, especially with regard to their impact on maintenance sub-processes. This includes life-cycle costing, expected reliability gains, maintainability enhancements, and the logistical feasibility of integration. Training needs and change management requirements are also factored into the decision-making process.

IMP.6 – Carry Out Realization Approved improvements are implemented under strict monitoring to ensure compliance with the defined requirements. The realization phase must respect time, budget, and quality constraints, ensuring the delivery of reliable and safe modifications.

IMP.7 – Verify Conformity with the Reliability, Maintainability, Safety, and Logistic Support Requirements Compliance is verified through a formal validation process. A notice of conformity is issued upon successful testing and acceptance, establishing the item’s readiness for deployment and integration into existing operations.

IMP.8 – Establish the Initial Maintenance Plan Based on the improvements, an initial maintenance plan is developed. This plan accounts for the improved characteristics of the item and is aligned with supplier recommendations and operational context. It is recorded in the maintenance information system and becomes the reference for ongoing maintenance execution.

IMP.9 – Determine the Initial Logistical Resources All material resources – including tools, spare parts, and documentation – are identified and prepared. These are aligned with the improved asset’s needs and form the foundation of sustained maintainability.

IMP.10 – Identify Skills and Training Needs New or adjusted maintenance procedures may require updated skill sets. This sub-process assesses the current capabilities of both internal and external personnel and identifies training or certification needs to ensure competent execution of maintenance on improved items.

Inputs and Outputs Key inputs for the IMP process include strategic direction from MAN.1, budget approvals (MAN.4), required improvements from OPT.3, and documentation or design practices from DOC.3 and DTA.10. Outputs encompass updated maintenance plans, conformity reports, improvement recommendations, defined training needs, and logistics support elements that are essential to operationalizing the upgrades.

Stakeholders and Interfaces Stakeholders include those responsible for initiating improvements, evaluating options, executing changes, and verifying results. The IMP process interfaces with numerous other maintenance processes (e.g., MAN, OPT, DOC, TOL, SPP) and must operate in harmony with budgetary, logistical, and operational constraints.

Indicators and Observations Key indicators include the number and cost of improvements (i1imp), conformity rates (i4imp), and measures of reliability, maintainability, and safety improvements (i5imp–i7imp). These KPIs ensure the strategic relevance and effectiveness of the improvements made.

In conclusion, the IMP process institutionalizes continuous improvement within the AMS framework, translating feedback into tangible technical and organizational enhancements. It elevates maintenance from a reactive function to a value-creating activity, reinforcing the strategic intent of sustainable and resilient asset performance.

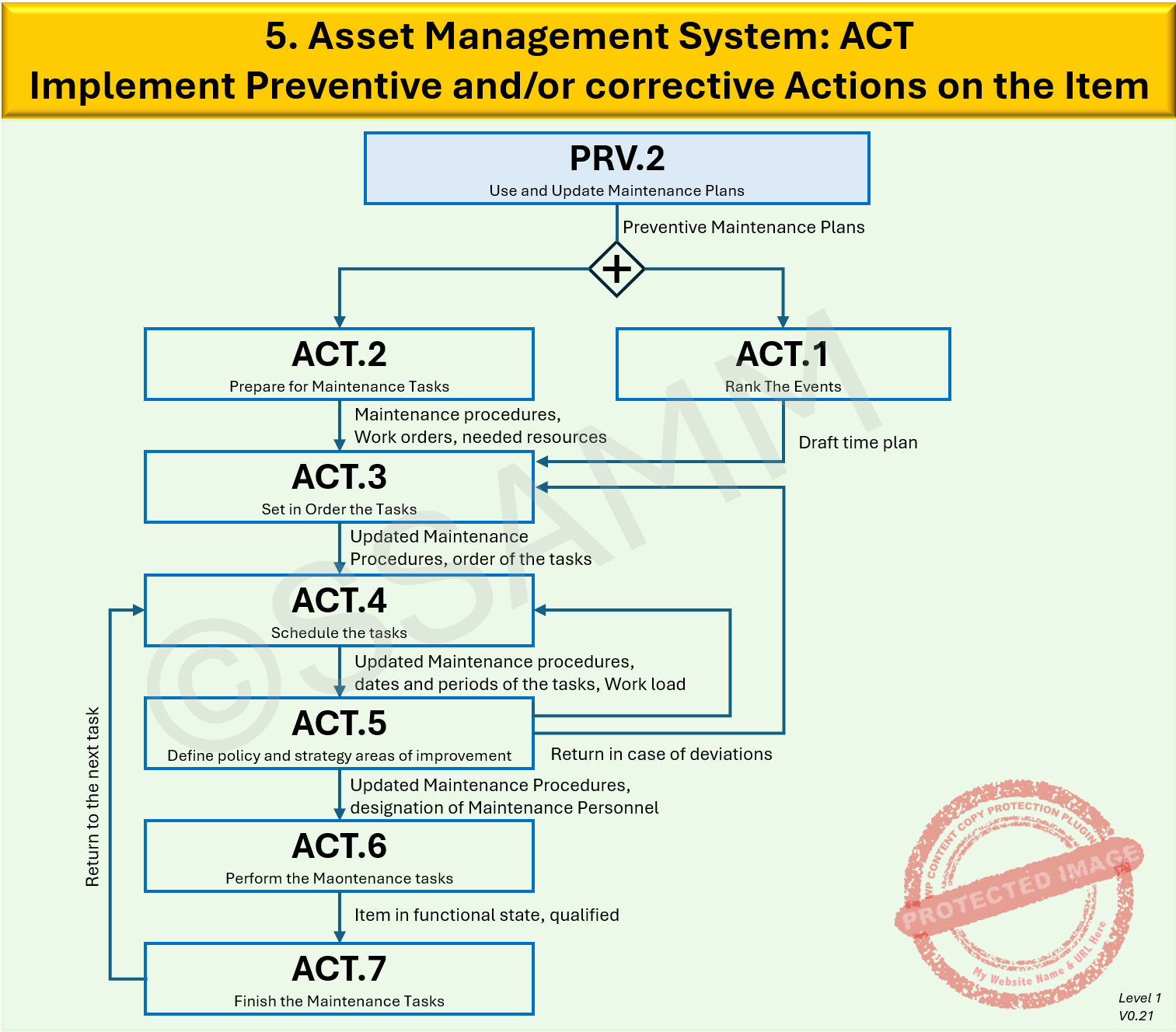

4.2.4 The ACT-5 process: Implement preventive and/or corrective actions on the item

ACT bridges the analytical outputs of PRV and COR with the physical restoration and upkeep of assets, thereby maintaining asset availability, reliability, and functional integrity.

Full Process Description Click Here

The ACT process consists of seven sequential sub-processes:

- ACT.1: Rank the events

- ACT.2: Prepare for the tasks

- ACT.3: Set in order the tasks

- ACT.4: Schedule the tasks

- ACT.5: Start the scheduled tasks

- ACT.6: Perform the maintenance tasks

- ACT.7: Finalise the maintenance tasks

Each sub-process serves a distinct purpose in transforming strategic maintenance intent into tangible execution.

ACT.1 – Rank the Events

The first step in the ACT process involves prioritizing maintenance activities—both preventive and corrective—based on severity, operational risk, and resource constraints. This ranking establishes a dynamic and regularly updated schedule that reflects criticality and feasibility.

ACT.2 – Prepare for the Tasks

Once events are ranked, the necessary information, resources, procedures, and safety protocols must be assembled. This step ensures that each task is executable within safe and efficient parameters. Preparation includes verifying tool availability, updating procedures, and conducting safety risk analyses.

ACT.3 – Set in Order the Tasks

This step determines the optimal sequence of maintenance operations, considering resource availability, task dependencies, and potential uncertainties. It results in a logical flow of tasks that maximize resource efficiency and minimize asset downtime.

ACT.4 – Schedule the Tasks

Task sequencing is followed by the creation of a formal schedule, assigning start and end times, allocating human and material resources, and finalizing workload estimates. This step harmonizes planning with operational constraints.

ACT.5 – Start the Scheduled Tasks

With the schedule in place, ACT.5 initiates the physical execution phase. Qualified personnel are assigned, and task readiness is confirmed. Any deviations or constraints encountered are fed back for rescheduling if necessary.

ACT.6 – Perform the Maintenance Tasks

This sub-process involves the physical execution of the maintenance tasks. Safety measures are enforced, procedures followed, and asset functionality restored. Deviations, anomalies, or complications are documented and addressed.

ACT.7 – Finalise the Maintenance Tasks

The final sub-process restores the site, returns the asset to the user, and collects execution data. Work orders are closed, resources released, and insights compiled for continuous improvement.

Throughout these sub-processes, ACT relies on extensive interconnections with other processes—such as PRV, COR, RES, TOL, SPP, SER, and DTA—to ensure that execution is well-informed, resource-efficient, and strategically aligned. The effectiveness of the ACT process is evaluated through indicators such as task completion rates, schedule adherence, resource utilization, and post-maintenance performance.

The ACT process exemplifies how EN17007 enables organizations to operationalize the AMS. It provides a robust, structured mechanism to execute maintenance in a way that supports the strategic intent defined in ISO 55000 and detailed through PRV and COR processes. By orchestrating maintenance execution from prioritization to final reporting, ACT ensures that maintenance is not only reactive but predictively and proactively aligned with the broader asset management system.

4.3 The Support Process

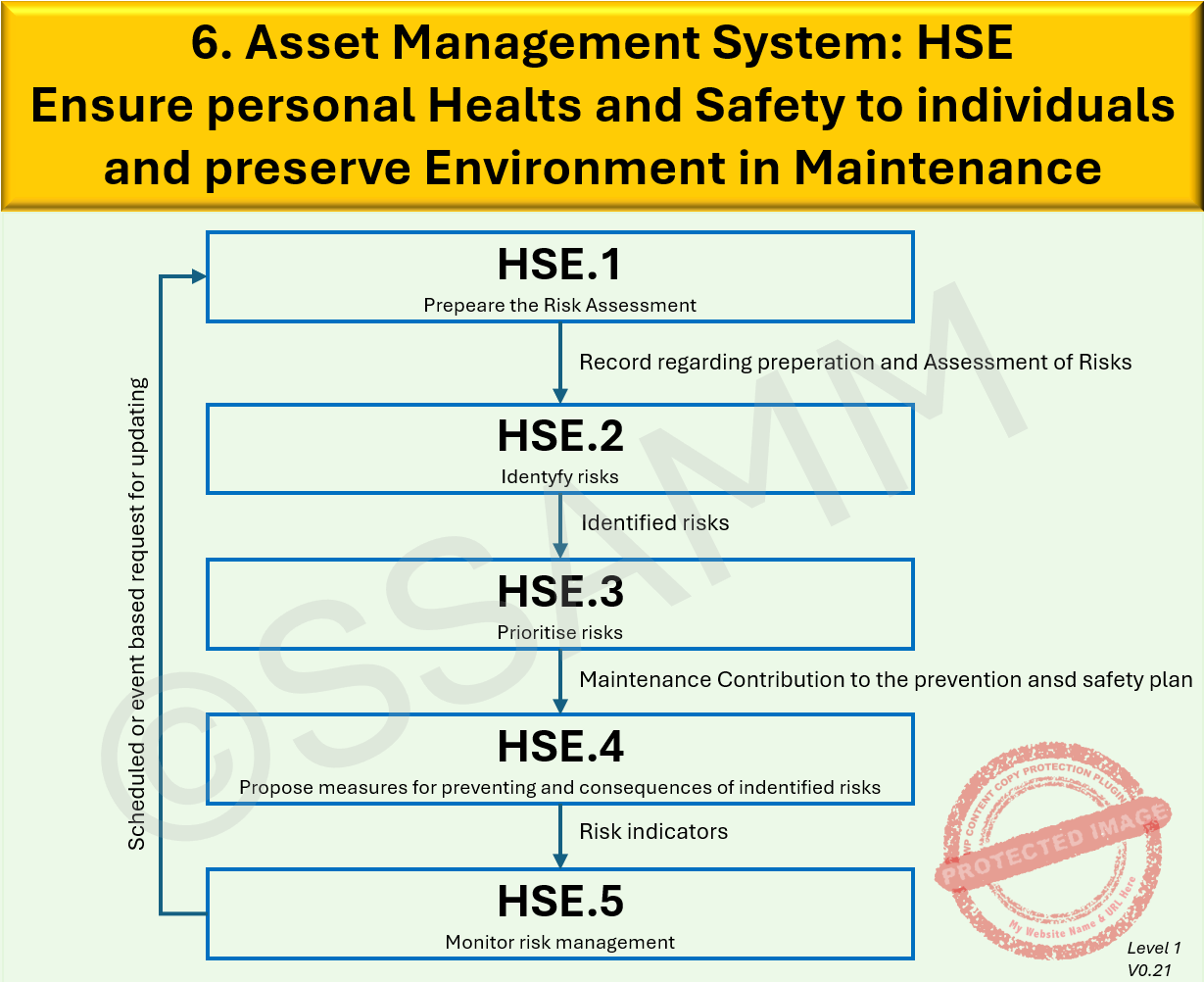

4.3.1 The HSE-6 process: Ensure personal health and safety to individuals and preserve environment in maintenance

By addressing both preventive and responsive actions, the HSE process plays a foundational role in risk management and legal compliance.

Full Process Description Click Here

The HSE process is structured into five core sub-processes:

- HSE.1 – Prepare the Risk Assessment: This sub-process defines the scope and boundaries of risk evaluations. It includes the identification of operational interfaces, environmental conditions, stakeholder involvement, and relevant regulatory frameworks. A multidisciplinary team is established to assess risks comprehensively.

- HSE.2 – Identify Risks: It involves recognizing hazards that may impact human safety and environmental protection. Using feedback, observations, and documented evidence, this step assesses potential exposure scenarios and their implications.

- HSE.3 – Prioritize Risks: Once identified, risks are evaluated in terms of probability, impact, and frequency. This enables the classification and prioritization of hazards to guide the allocation of preventive resources effectively.

- HSE.4 – Propose Preventive and Mitigating Measures: Preventive and mitigating measures are identified and selected based on their technical and economic viability. These measures address residual risk and are documented for operational deployment.

- HSE.5 – Monitor and Review Risk Management: This ongoing sub-process ensures continuous improvement by monitoring regulatory compliance, analyzing performance indicators, and maintaining an up-to-date risk assessment based on feedback and incident data.

The HSE process interfaces with several other key maintenance processes, including:

- ACT.2 – where risk data informs task preparation.

- MAN.1 and MAN.5 – where HSE considerations are reflected in policy, strategy, and oversight.

- DOC.6 and DTA.11 – providing the documentation and indicators for regulatory and operational alignment.

Key indicators used in the HSE process include:

- Rates and severity of maintenance-related accidents (i1hse, i2hse)

- Medical care cases and near-miss incidents (i3hse, i4hse)

- Waste and discharge volumes (i5hse, i6hse)

- Days off and days without accidents (i7hse, i8hse)

- Risk assessment coverage and update frequency (i10hse, i11hse)

Through rigorous application of this process, organizations can:

- Minimize harm to personnel and the environment.

- Enhance resilience and compliance with safety regulations.

- Embed a culture of safety within maintenance practices.

In summary, the HSE process is an indispensable element of maintenance within the AMS framework, enabling organizations to uphold sustainability, ethical responsibility, and legal accountability across all maintenance interventions.

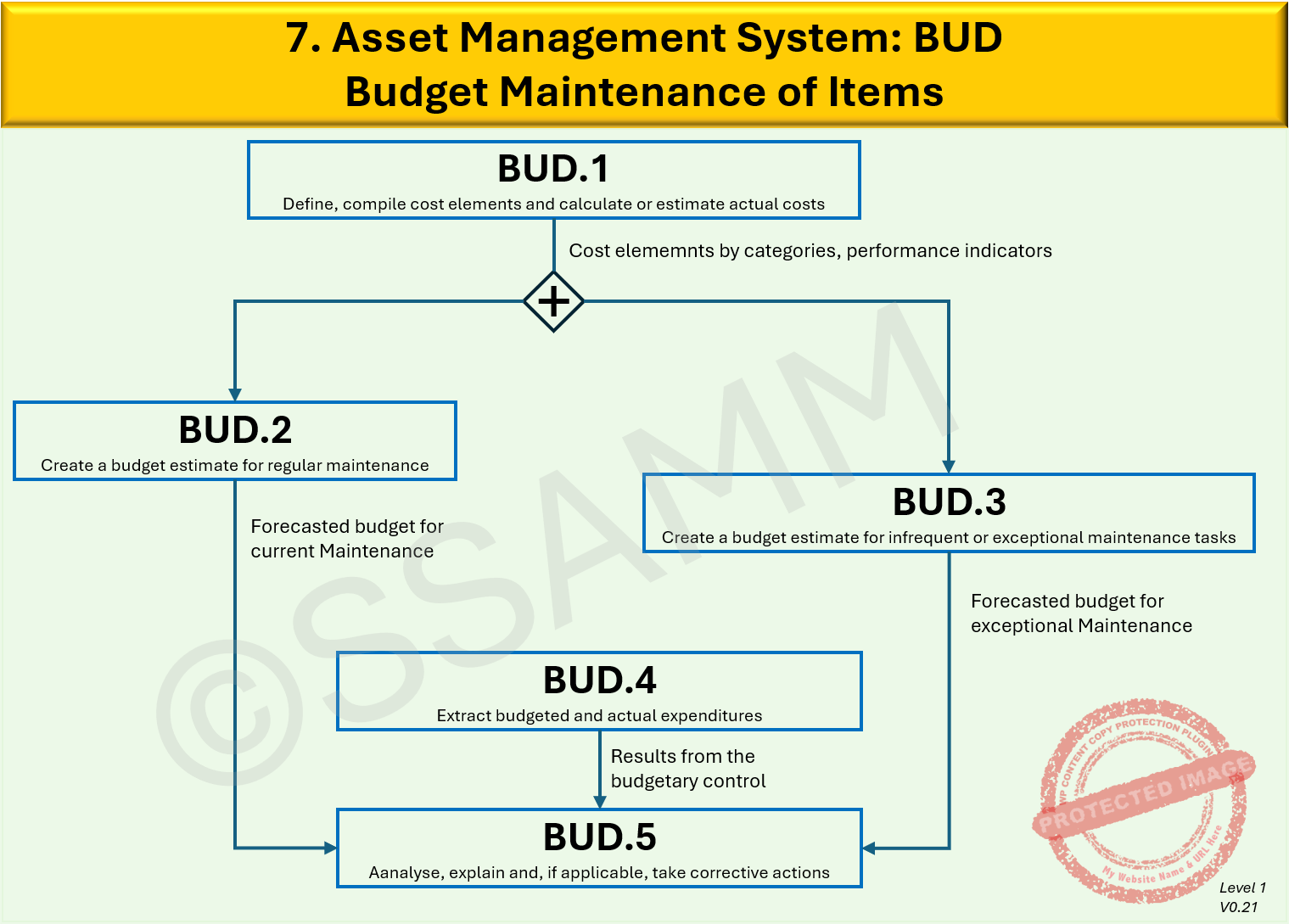

4.3.2 The BUD-7 process: Budget Maintenance of Items

Purpose and Objectives

The primary objective of the BUD process is to ensure sound economic planning for maintenance activities over short, medium, and long-term time horizons. It encompasses regular operational maintenance expenditures (OPEX) as well as exceptional maintenance actions often classified under capital investments (CAPEX). By categorizing maintenance-related costs, the process ensures financial resources are appropriately allocated, monitored, and revised in accordance with actual asset performance, emerging risks, and evolving operational demands.

Key Activities and Sub-Processes

BUD.1 – Define, Compile Cost Elements, and Estimate Actual Costs

This sub-process involves identifying and allocating maintenance costs across defined cost categories. These include internal and external labor, spare parts and consumables, health and safety measures, training, and supporting documentation. Cost allocations are structured by item (e.g., equipment or facility), maintenance type (preventive, corrective, improvement), and expenditure destination. This foundational data is essential for downstream planning and analysis.

BUD.2 – Create a Budget Estimate for Regular Maintenance

Budget estimates are developed for short-term maintenance requirements, typically over one or more fiscal cycles. These include routine tasks and shared overhead costs such as facility management and centralized administrative support. This step ensures day-to-day maintenance operations are financially resourced and aligned with corporate budget cycles.

BUD.3 – Create a Budget Estimate for Exceptional Maintenance Tasks

This activity addresses the need for medium- and long-term financial planning of infrequent or large-scale maintenance tasks, including overhauls, system upgrades, and lifecycle extension interventions. It includes both item-specific and general overhead costs, supporting capital budgeting, investment appraisals, and funding strategies.

BUD.4 – Extract Budgeted and Actual Expenditures

The process compiles budgeted and actual expenditures across all items and categories. This allows for variance analysis, enabling organizations to evaluate budget performance and derive cost trends. The classification by maintenance type and resource destination supports more granular financial control and auditability.

BUD.5 – Analyze, Explain, and Take Corrective Actions

Deviations between planned and actual costs are systematically analyzed. The insights generated inform corrective measures, which are then escalated to management for review and strategic recalibration. This creates a closed feedback loop, enhancing the maturity of financial planning and supporting adaptive asset management.

Inputs and Outputs

The process requires several key inputs:

- Basic cost allocation data (e.g., per asset or system);

- Historical and current financial data (DTA.10);

- Performance indicators and past budget feedback (DTA.11);

- Best practices from internal/external benchmarking (OPT.5);

- Strategic objectives and organizational direction (MAN.1).

The main outputs are:

- Consolidated actual vs. forecasted budget data;

- Documented budget gaps and associated root causes;

- Updated financial strategies for maintenance.

Stakeholder Involvement and Interfaces

Budgeting is inherently cross-functional, requiring coordination among finance departments, asset managers, maintenance planners, and executive leadership. The BUD process interfaces closely with:

- MAN.1 (strategic direction);

- MAN.4 (approval of economic plans);

- DTA.10 and DTA.11 (data collection and analysis);

- OPT.5 (continuous improvement and best practices).

Constraints and Critical Success Factors

Reliable budgeting depends on consistent and high-quality data, robust historical records, and integration with the enterprise’s financial systems. Inaccuracies or gaps in data can undermine decision-making. Additionally, the process must support real-time or near-real-time monitoring to enable proactive corrections.

Indicators and Observations

To evaluate process effectiveness, the following indicators are applied:

- (i1bud) Budget deviations detected;

- (i2bud) Number of deviations analyzed and acted upon;

- (i3bud) Budget allocation by maintenance type (corrective, preventive, improvement);

- (i4bud) Allocation by indenture levels (system/subsystem/component);

- (i5bud) Allocation across cost types (labor, materials, energy, etc.);

- (i6bud) Reporting frequency and timeliness.

This structured budgeting process not only enables financial discipline within maintenance but also reinforces broader asset management goals. Through integration with the AMS, it supports lifecycle optimization, justifies strategic investments, and enhances the ability to balance risk, cost, and performance—central tenets of ISO 55000:2024.

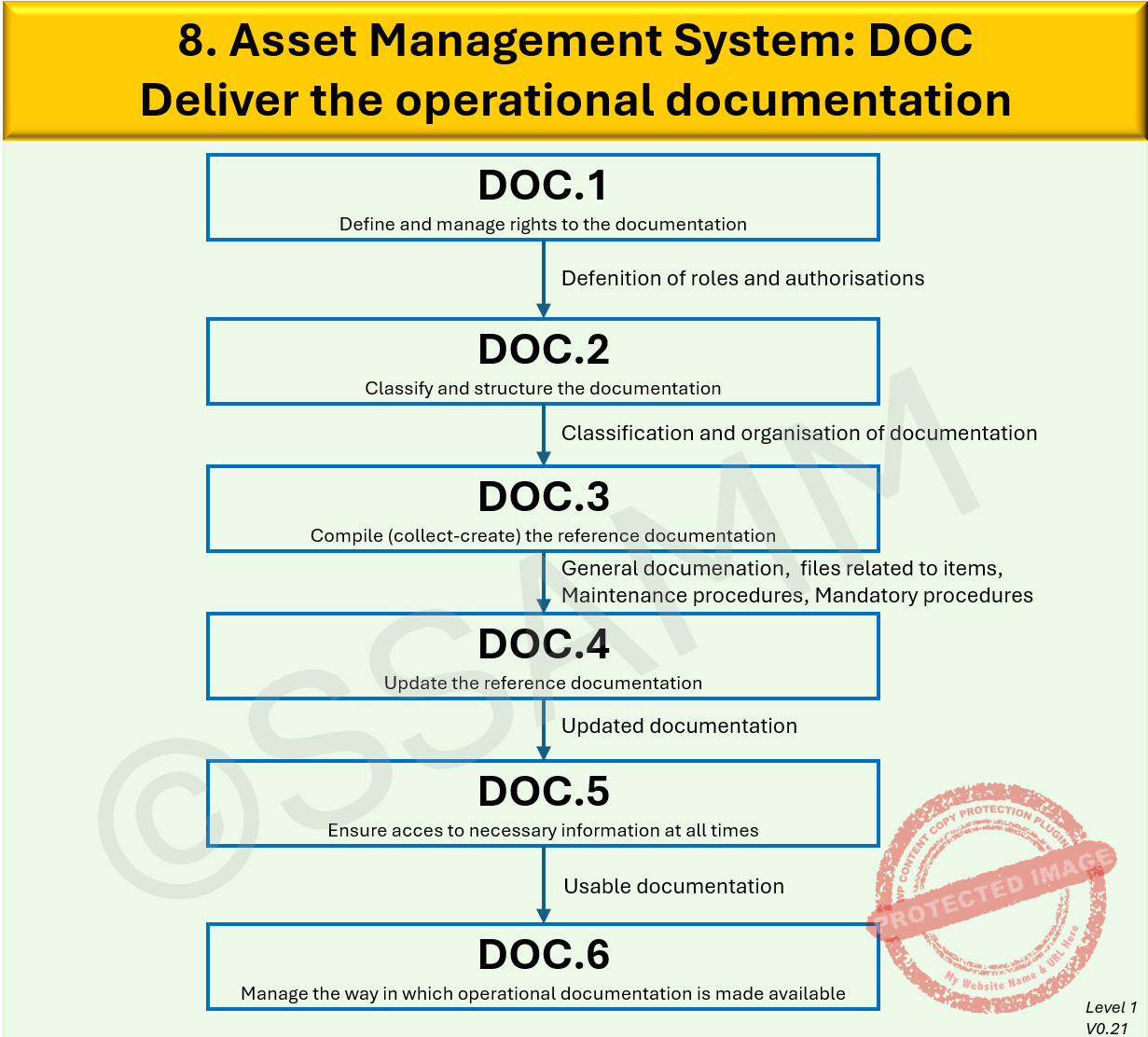

4.3.3 The DOC-8 process: Documentation Management for Maintenance Excellence

Purpose of the DOC Process

The primary objective of the DOC process is to provide updated, usable, and contextually relevant documentation to all individuals involved in maintenance activities. This includes technicians, engineers, contractors, and managers, ensuring that the information required to safely and effectively plan, perform, and evaluate maintenance tasks is always accessible. Furthermore, by optimizing access and storage, the DOC process helps reduce logistical delays and supports overall maintenance efficiency.

Key Activities and Elementary Processes

The DOC process is composed of six interconnected elementary processes:

- DOC.1 – Define and manage rights to the documentation: Roles and responsibilities are assigned based on organizational structure, giving individuals specific rights to create, consult, or update documents in accordance with their duties.

- DOC.2 – Classify and structure the documentation: Documentation must be categorized by type (e.g., technical manuals, maintenance procedures, regulatory records) and structured by purpose to ensure intuitive access and usability.

- DOC.3 – Compile reference documentation: This includes gathering general references (standards, supplier catalogues), item-specific records (specifications, drawings), procedural documents (maintenance plans, checklists), and safety/environmental documents (e.g., material safety data sheets).

- DOC.4 – Update the reference documentation: Timely and accurate updates are critical to maintaining document quality. Revisions must reflect editorial or substantial changes and must be carried out promptly by authorized personnel.

- DOC.5 – Ensure access to necessary information at all times: Regardless of format (paper or digital), documentation must be accessible during the entire lifecycle of the item. This requires proper storage, backup, and interface solutions.

- DOC.6 – Manage the availability of operational documentation: Procedures must be in place to govern how users access documents generated from updated references. This includes managing user interfaces, digital libraries, and physical archives.

Input and Output Data

Input data to the DOC process include organizational information from MAN.3, initial maintenance plans (MRQ.9, IMP.8), conformity notices (MRQ.8, IMP.7), spare parts documentation (SPP.7), external sources (laws, standards, suppliers), and best practices (OPT.5).

Output data include:

- Structured general documentation

- Technical files and operational maintenance procedures

- Mandatory compliance-related documents

- A defined organizational structure for documentation responsibilities

Stakeholders and Interfaces

The specific stakeholders executing and benefiting from the DOC process will vary by organization but typically include maintenance planners, technical writers, safety officers, and external service providers. Key interfaces are established with processes such as ACT.2 (preparation of tasks), HSE.1 (risk assessment), IMP.7–8 (item improvement), MAN.3 (role assignment), PRV.1–2 (preventive analysis and plans), and SPP.7 (spare parts information).

Constraints and Considerations

Implementing a robust DOC process often requires significant investment in hardware, software, and digitalization infrastructure. Furthermore, ensuring consistency across platforms and departments is an ongoing challenge. The cost of documentation can represent up to 15% of an asset’s value, with annual maintenance of that documentation costing around 2% of the total.

Performance Indicators

To monitor and evaluate the effectiveness of the DOC process, the following indicators are suggested:

- (i1doc) Coverage of documentation by type, item, and criticality

- (i2doc) Instances where documentation is missing when needed

- (i3doc) Frequency of delayed updates

- (i4doc) Proportion of non-up-to-date documents

- (i5doc) Readability, consistency, and user comprehensio

The DOC process is not a peripheral activity but a central enabler of sustainable, compliant, and high-performance maintenance. By managing documentation as a strategic asset, organizations can foster knowledge continuity, operational safety, regulatory compliance, and continuous improvement. This structured approach aligns directly with ISO55001’s requirements for information management and supports the asset management system’s overall integrity.

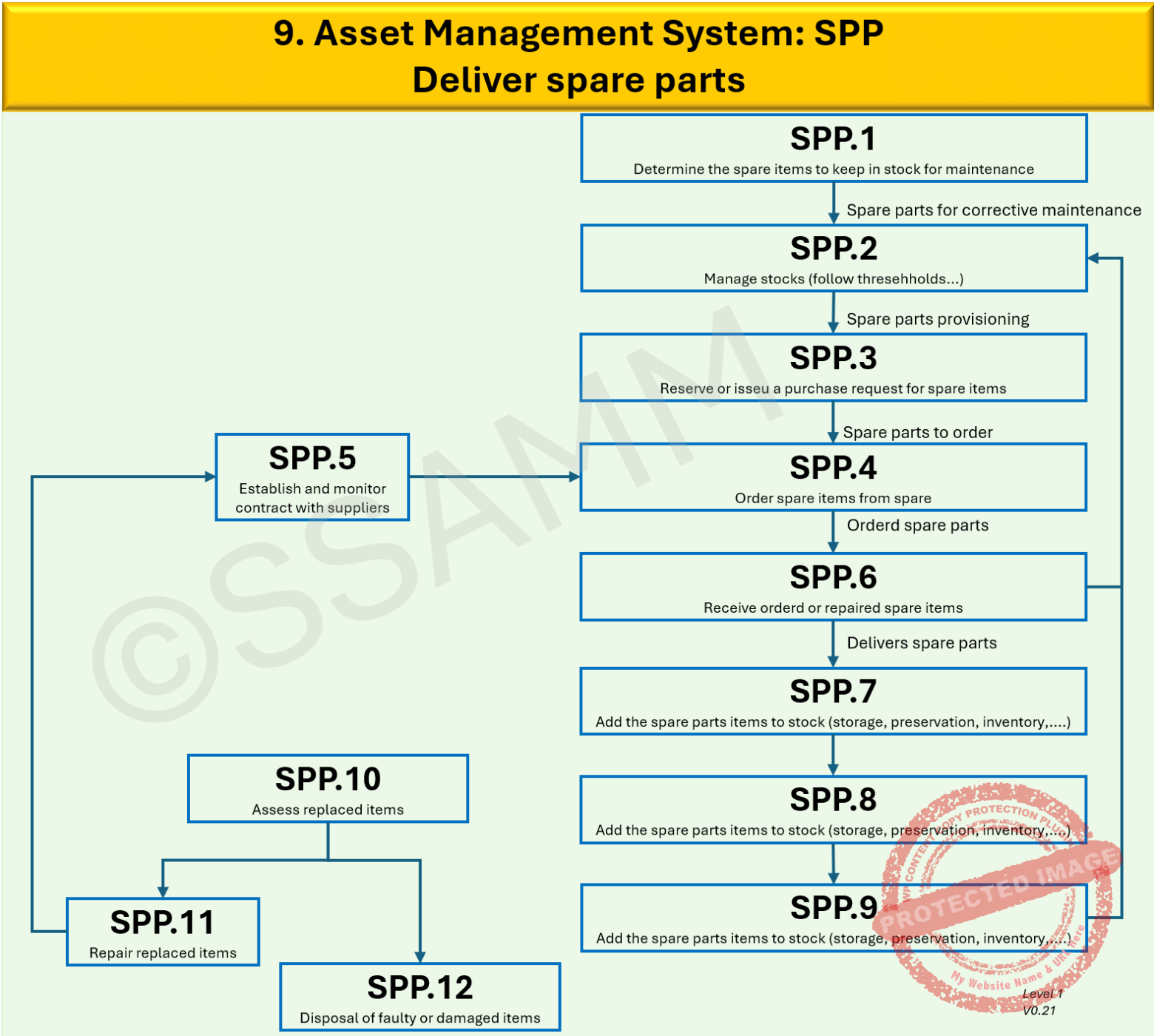

4.3.4 The SPP-9 process: Spare Parts Provision and Lifecycle Management

As a critical logistical pillar of the Asset Management System (AMS), this process directly supports operational continuity and maintenance effectiveness by enabling seamless access to replacement parts.

Full Process Description Click HereThe SPP process integrates strategic inventory planning, procurement, and physical stock management to optimize availability while minimizing waste, obsolescence, and excess stock. It is aligned with performance-based objectives and complies with safety, regulatory, and environmental requirements throughout the lifecycle of spare items.

SPP.1 – Define Stock Requirements

Initial stock needs are determined through supplier recommendations, experience, and logistical support analyses. Spare parts are selected based on criticality, usage patterns, and risk of unavailability. Each item is uniquely identified and recorded for traceability.

SPP.2 – Manage Spare Parts Inventory

Stock levels are managed to balance availability with cost. Inventory control aims to prevent both overstocking and shortages. Principles of lean inventory and just-in-time provisioning are employed where feasible.

SPP.3 – Issue Purchase Requests

Based on maintenance forecasts and stock assessments, purchase requests are generated. Items for preventive maintenance are ideally procured based on planned schedules, whereas stock reserves are maintained primarily for corrective needs.

SPP.4 – Order Spare Parts

Procurement is executed according to supplier selection criteria including delivery time, quality, cost, and risk of obsolescence. Orders are placed based on approved purchasing rules and specifications.

SPP.5 – Establish and Monitor Supplier Contracts