Publication reference

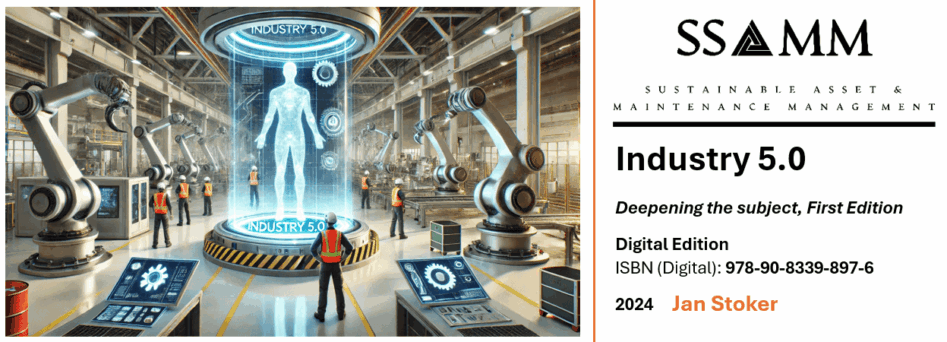

Title: Industry 5.0: Deepening The Subject

Author: Benjamin Stoker

Publisher: SSAMM (Click Here)

Publication platform: SSAMM Academy – ssammeducation.com

ISBN/EAN: 978-90-8339-897-6

This restricted web article provides an overview and selected extracts from the publication Industry 5.0: Deepening The Subject (ISBN/EAN 978-90-8339-897-6). It is made available exclusively to registered SSAMM Academy clients as part of their personal, non-transferable licence.

© 2024 Stoker / SSAMM. All rights reserved.

This content is provided under a personal, non-transferable licence. Unauthorised sharing of logins, screenshots, files or copies (in whole or in part) is not permitted

In his ‘Learning Journey’ of defining Asset & Maintenance Management, lecturer/Researcher Jan Stoker of SSAMM write his finding and insights during this journey. Started in 2013 with his research one of his goals is to understand Asset & Maintenance Management within the ISO55000 framework. Currently his main goal is to describe and define Asset Management 5.0 based on this article. Check the related article’s on this page.

- Publication 5 december 2021

- Updated 15 June 2022 ME integration

- Updated 17 September 2023 added Maintenance Management 5.0

- Updated 8 October 2023 Integrating Asset & Maintenance Management

- Updated 15 October Integrating Asset Management System

- Updated 7 november Integrating rise of A.I.

- Industry 5.0: Deepening The Subject

- The Asset & Maintenance Management Pyramid

- The Digital Line of Sight: Deepening the subject

- Maintenance Management: Deepening the subject

- Digital Twin: Deepening the subject

- The Asset Management BowTie

- Conference Article

- Article IR5.0 Human-Centric

- The IR5.0 elephant in the room

- Decision-making with AI

- AM 5.0: Balancing Risk, Performance and Value

Welcome to Industry 5.0, where technology and humanity converge to create a more sustainable, human-centric, and resilient industrial ecosystem. Unlike its predecessors, Industry 5.0 transcends profit-focused goals, prioritizing the well-being of individuals, communities, and the planet. In his learning journey, the author will share his findings in exploring and defing what it means to achieve Asset Management 5.0 and Maintenance Management 5.0, incorporating elements such as sustainability, human-centricity, and resilience. This transformative era challenges leaders in Asset and Maintenance Management to rethink traditional practices and adapt to an evolving landscape that emphasizes collaboration, sustainability, and resilience. The integration of frameworks such as the Asset Management Lemniscate, Asset Management Bow-Tie , and the Maintenance Framework offers essential guidance in navigating this shift and unlocking the full potential of Industry 5.0. Industry 5.0 builds upon the technological advancements of Industry 4.0, which revolutionized manufacturing and production through automation, IoT, and data-driven decision-making. However, Industry 5.0 introduces a deeper focus on human-centricity and sustainability, where technology enhances—not replaces—human roles. Within this context, asset and maintenance management becomes pivotal, ensuring that physical assets are not only reliable and efficient but also sustainable and adaptable. The Asset Management Lemniscate provides a dynamic feedback loop, allowing data and insights from maintenance activities to refine asset strategies continuously, ensuring that these strategies evolve in alignment with Industry 5.0 principles. Central to this transformation is the Asset Management BowTie, a model that visualizes the connection between risks, preventive measures, and corrective actions within maintenance processes. The BowTie helps organizations strike a balance between risk prevention and mitigation, ensuring that maintenance actions are proactive, adaptive, and aligned with broader organizational goals. Simultaneously, the Maintenance Framework, with its categorization of Management, Realization, and Support processes, ensures a structured and systematic approach to maintenance, bridging the gap between strategic goals and operational realities. As we delve deeper into the implications of Industry 5.0, it becomes evident that Asset Management 5.0 and Maintenance Management 5.0 are not just technical upgrades but philosophical shifts. They emphasize sustainability, resilience, and collaboration, with the aim of fostering a carbon-neutral, energy-efficient, and socially responsible industrial future. By embracing change, leveraging innovative frameworks, and fostering collaboration across disciplines, we can unlock the full potential of both people and technology, paving the way for a sustainable, human-centric, and resilient tomorrow. Together, we can transform the challenges of Industry 5.0 into opportunities for growth and impact. Maintenance Fundamentals SAM, First Edition Keynote Āpōpō Congres 2026 Follow Sustainable Asset Management for latest updates

Countdown SSAMM Academy Module 1

Explore the SSAMM Academy Asset Management and Maintenance Management courses.

Click Here for the Smart information page

Author: Ing. Jan Stoker MSc. MEng. AMCP. CFAM. Follow Jan Stoker

Introduction: A.I. ….. The Rise of a Concept

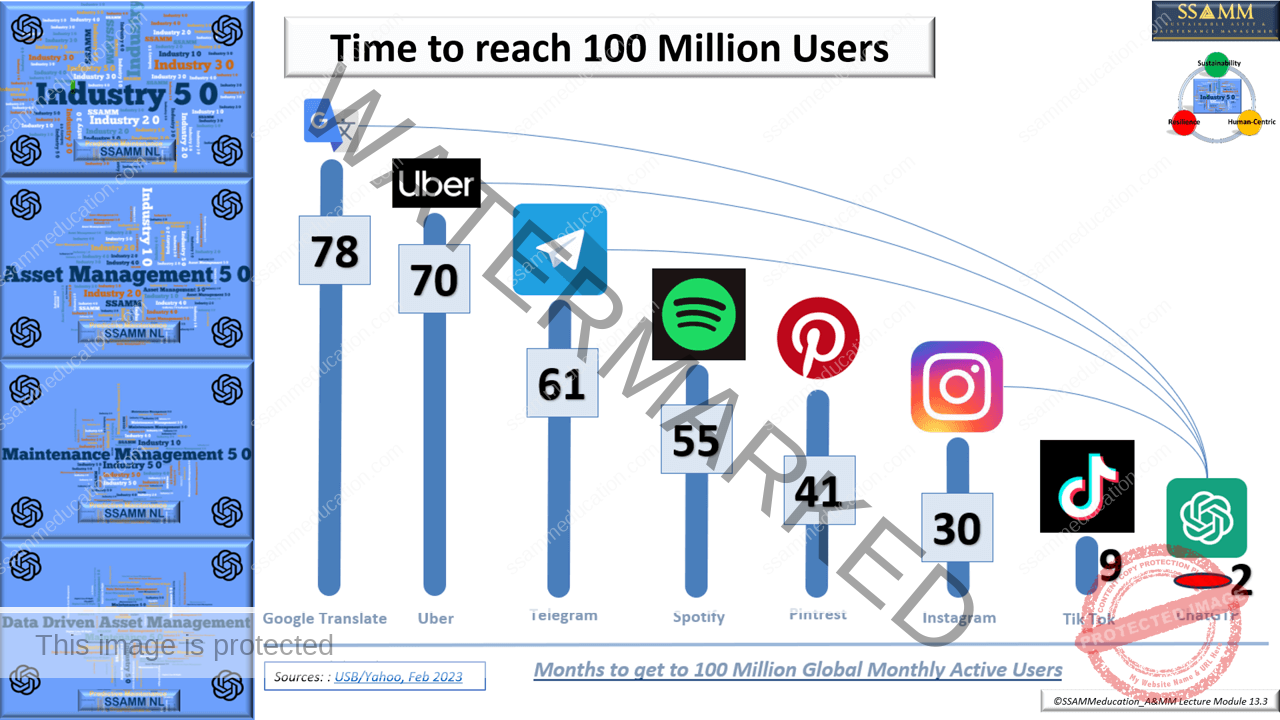

These numbers are not only a testament to the growing demand for innovative technology, but also a clear indication of the rapid evolution of artificial intelligence (A.I.).

As we continue to witness the exponential growth and adoption of A.I. in various industries, it is becoming increasingly urgent for businesses to embrace Industry 5.0. In the context of Asset & Maintenance Management, Industry 5.0 will revolutionize the way we approach and manage assets and maintenance tasks.With the help of A.I., businesses can now predict equipment failures and proactively schedule maintenance before any disruptions or downtime occur. This not only improves efficiency and reduces costs, but also increases safety for workers by minimizing their exposure to potentially hazardous situations.

The concept of “Industry 5.0” refers to the fifth industrial revolution, which emphasizes the integration of human creativity and decision-making with the technological advances that have emerged from previous industrial revolutions. It is a natural evolution from Industry 4.0, which focused primarily on the integration of digital technologies like the Internet of Things (IoT), big data, artificial intelligence, and automation in manufacturing processes.

While the phrase “Industry 5.0” has been used in various contexts around the world, the European Union (EU) has been one of the main driving forces behind formalizing and promoting its concepts. Here are some key points on the origin and objectives of Industry 5.0 as appointed by the EU in 2021:

-

Human-Centric Approach: Industry 5.0 emphasizes the role of human beings in the production process. The EU envisions a future where people and machines work alongside each other, leveraging the strengths of both.

-

Sustainability: A significant aspect of Industry 5.0, as understood by the EU, is sustainability. This involves creating products and processes that are not only efficient but also environmentally friendly and socially responsible.

-

Overcoming Limitations of Industry 4.0: While Industry 4.0 provided numerous technological advances, it also led to concerns about job displacement due to automation. Industry 5.0 seeks to address this by promoting the idea that humans and robots can coexist in the workplace, with each complementing the other.

-

Enhancing Creativity and Innovation: By leveraging human creativity and decision-making in conjunction with automation and digital technologies, Industry 5.0 seeks to foster more innovative solutions in production and other industrial processes.

-

Official Communications: In 2021, the European Commission had several discussions and published materials emphasizing the importance of the transition to Industry 5.0. These communications highlighted the strategies and vision for the EU in shaping the future of its industrial landscape.

-

Support for SMEs: Recognizing the challenges small and medium-sized enterprises (SMEs) may face in this transition, the EU also laid out plans to support these entities through various means, ensuring that they are not left behind.

-

Skills and Training: Preparing the workforce for Industry 5.0 is crucial. As such, there’s an emphasis on upskilling, reskilling, and continuous learning to ensure that workers can adapt to the changing industrial environment.

The EU’s commitment to Industry 5.0 aims to position Europe at the forefront of the next industrial transformation, ensuring that it remains competitive globally while also addressing societal and environmental challenges.

1. Defining Industry 5.0

In this article, we will explore Industry 5.0, its defining characteristics and components, and the importance of asset and maintenance management in the modern era.

Even though Industry 5.0 is a relatively new concept, some early academic writing describing the main features of this notion exists. The analysis of the Industry 5.0 literature in scienfific papers (see reference articles’) shows a lot of uncertainty about what it will bring and how it will disrupt business in detail, as well as about its potential to break down barriers between the real world and the virtual one.

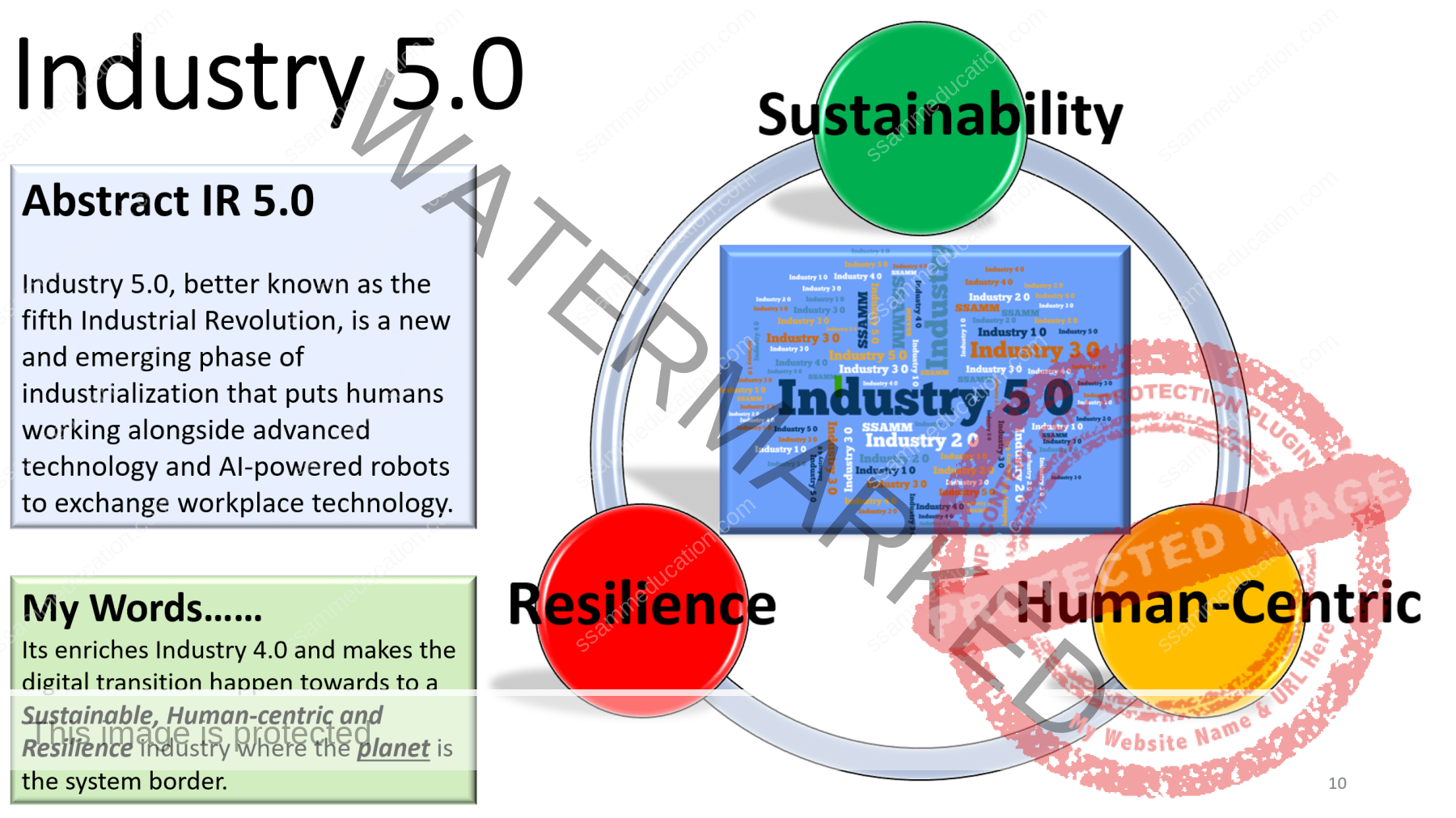

Based on the literature review and forward-looking analysis, Industry 5.0 will be defined by a re-found and widened purposefulness, going beyond producing goods and services for profit. This wider purpose constitutes three core elements: human-centricity, sustainability and resilience.

Industry 5.0, better known as the fifth Industrial Revolution, is a new and emerging phase of industrialization that puts humans working alongside advanced technology and AI-powered robots to exchange workplace technology.

A purely profit-driven approach has become increasingly untenable. In a globalised world, a narrow focus on profit fails to account correctly for environmental and societal costs and benefits. For industry to become the provider of true prosperity, the definition of its true purpose must include social, environmental and societal considerations. This includes responsible innovation, not only or primarily aimed at increasing cost-efficiency or maximising profit, but also at increasing prosperity for all involved: investors, workers, consumers, society, and the environment.

1.1 Human-Centric

Rather than taking emergent technology as a starting point and examining its potential for increasing efficiency, a human-centric approach in industry puts core human needs and interests at the heart of the production process. Rather than asking what we can do with new technology, we ask what the technology can do for us. Rather than asking the industry worker to adapt his or her skills to the needs of rapidly evolving technology, we want to use technology to adapt the production process to the needs of the worker, e.g. to guide and train him/her. It also means making sure the use of new technologies does not impinge on workers’ fundamental rights, such as the right to privacy, autonomy and human dignity.

Human-Centric Prioritizes the integration of advanced technologies to enhance human capabilities, foster collaborative work environments, and deliver personalized solutions, ultimately improving quality of life and ensuring human well-being. It Emphasizes the synergy between humans and technology to create a harmonious and efficient future.

Human-centricity in the context of Industry 5.0 refers to placing human beings at the center of industrial processes, technologies, and decision-making, ensuring that technology serves human needs, enriches human experiences, and augments human capabilities. It represents a shift from solely focusing on automation and efficiency to a more balanced approach where human well-being, creativity, and collaboration are of paramount importance.

Here’s a more detailed breakdown of the human-centric approach in Industry 5.0:

-

Humans and Machines Collaborating: Instead of viewing automation and robotics as a replacement for human workers, Industry 5.0 views them as tools to enhance human capabilities. This means machines take over repetitive, hazardous, or strenuous tasks, while humans focus on tasks that require creativity, critical thinking, emotional intelligence, and complex decision-making.

-

Ergonomics and Workplace Safety: A human-centric approach also means designing workspaces and tools that prioritize the comfort, safety, and well-being of human workers. For instance, wearable technologies might be used to monitor workers’ health, or augmented reality could be employed for better training experiences.

-

Job Satisfaction and Meaningful Work: With a focus on human-centricity, there’s an emphasis on creating jobs that provide a sense of purpose and satisfaction. By eliminating mundane tasks through automation, workers can engage in more value-added activities, leading to increased job satisfaction.

-

Ethical Considerations: Human-centricity takes into account the broader ethical implications of technology. This means considering the potential social, psychological, and economic impacts of new technologies and ensuring they’re implemented in ways that benefit humanity as a whole.

-

Customization: Industry 5.0’s human-centric approach can also lead to more personalized products and services. Since humans are at the center of the production process, there’s a greater emphasis on tailoring products to individual preferences and needs.

-

Continuous Learning and Skill Development: Recognizing the rapid pace of technological change, a human-centric approach emphasizes the need for ongoing education and skill development. This ensures that workers remain relevant and can harness new technologies effectively.

-

Emphasizing Social and Emotional Skills: While technical skills remain essential, Industry 5.0 recognizes the unique qualities that humans bring to the table, such as empathy, collaboration, and communication. These skills become even more vital in a human-centric industrial environment.

In essence, the human-centric approach of Industry 5.0 challenges the notion that humans and machines are in competition. Instead, it posits that they can collaborate harmoniously, with technology serving to elevate human potential and well-being.

1.2 Sustainability

For industry to respect planetary boundaries, it needs to be sustainable. It needs to develop circular processes that re-use, re-purpose and recycle natural resources, reduce waste and environmental impact. Sustainability means reducing energy consumption and greenhouse emissions, to avoid depletion and degradation of natural resources, to ensure the needs of today’s generations without jeopardising the needs of future generations. Technologies like AI and additive manufacturing can play a large role here, by optimising resource-efficiency and minimising waste.

Sustainability Revolves around eco-friendly practices, renewable resources, and circular economy models. It aims to Minimize environmental impact, promote energy efficiency, and foster responsible production and consumption, ensuring a greener and more sustainable future for generations to come.

Sustainability in the context of Industry 5.0 is about ensuring that industrial processes and outputs are not only efficient but also environmentally friendly, socially responsible, and economically viable. It encompasses a holistic approach that takes into consideration the long-term impacts of industrial activities on the planet, society, and the economy. This reflects a growing global awareness of the need to address issues such as climate change, resource depletion, and social inequality.

In the context of Industry 5.0, sustainability can be described in the following ways:

Environmental Sustainability:

-

Resource Efficiency: Utilizing resources more effectively and reducing waste. This might include reusing materials, reducing water and energy consumption, and optimizing supply chains.

-

Clean Energy: Transitioning to renewable energy sources in manufacturing processes and operations to reduce carbon footprints.

-

Eco-friendly Manufacturing: Adopting technologies and methods that cause minimal harm to the environment. This can include green chemistry, cleaner production methods, and waste reduction techniques.

Social Sustainability:

-

Ethical Labor Practices: Ensuring fair wages, safe working conditions, and respecting workers’ rights.

-

Inclusive Growth: Creating opportunities for all segments of the population, reducing inequalities, and ensuring that technological advancements benefit a broad range of people.

-

Community Engagement: Engaging with local communities, understanding their needs, and ensuring that industrial activities do not harm them.

Economic Sustainability:

-

Long-term Viability: Adopting business models that are not only profitable but also resilient and adaptable to changing economic landscapes.

-

Local Economies: Supporting local economies by sourcing materials and labor locally, leading to more distributed economic benefits.

Circular Economy:

-

Industry 5.0 emphasizes the transition from a linear economy (where we extract, produce, consume, and discard) to a circular one, where products are designed for reuse, recycling, and regeneration.

-

This approach aims to minimize waste and make the most of resources, changing the very way products are designed, produced, and consumed.

Digital Tools for Sustainability:

-

Employing advanced digital technologies such as the Internet of Things (IoT), big data analytics, and artificial intelligence to monitor and optimize energy usage, track carbon footprints, and predict maintenance needs.

-

Using technology to develop sustainable solutions, like AI-driven simulations that can test the environmental impact of a product in its design phase.

Regenerative Practices:

-

Going beyond just minimizing harm, but actively seeking to restore and rejuvenate the environment. This could involve practices like reforestation, soil regeneration, and restoring natural habitats.

Industry 5.0’s focus on sustainability acknowledges that for industries to thrive in the long term, they need to operate in harmony with the environment and society. It recognizes that industries can’t just be takers but must also be caretakers of the planet and its inhabitants.

1.3 Resilliance

Resilience refers to the need to develop a higher degree of robustness in industrial production, arming it better against disruptions and making sure it can provide and support critical infrastructure in times of crisis. Geopolitical shifts and natural crises, such as the Covid-19 pandemic, highlight the fragility of our current approach to globalised production. It should be balanced by developing sufficiently resilient strategic value chains, adaptable production capacity and flexible business processes, especially where value chains serve basic human needs, such as healthcare or security.

Resilience Refers to the ability of businesses to adapt, recover, and thrive amidst challenges, disruptions, and technological advancements. It Involves robust risk management, agile strategies, and continuous innovation to ensure long-term success and competitiveness.

It refers to thecapacity of industrial systems, processes, and businesses to anticipate, absorb, adapt to, and rapidly recover from potential disruptions. Such disruptions can be diverse, ranging from economic downturns, supply chain interruptions, cyber-attacks, natural disasters, to pandemics. Industry 5.0 recognizes the need for industries to be more agile and adaptive in an increasingly complex and uncertain global landscape.

Here’s a breakdown of resilience as it relates to Industry 5.0:

Adaptive Supply Chains:

- Diversification: Rather than relying heavily on a single supplier or region, industries should diversify their supply chains to reduce vulnerability.

- Digital Twins: Creating digital replicas of physical systems to simulate and analyze potential disruptions and develop appropriate responses.

- Real-time Monitoring: Using sensors, IoT, and data analytics to monitor the entire supply chain in real-time, allowing for swift detection and response to any disruptions.

Cybersecurity:

- As industries become more interconnected and digitized, they are also more vulnerable to cyber threats. Resilience involves robust cybersecurity measures to protect data, intellectual property, and operational integrity.

- Regular updates, training, and simulations to ensure systems and employees are prepared to counter cyber-attacks.

Decentralization:

- Decentralized production models, such as distributed manufacturing, can reduce the risk associated with centralized systems. If one unit faces a disruption, others can continue to function.

Flexible Manufacturing:

- Using technologies like additive manufacturing (3D printing) that can swiftly switch between products, allowing industries to adapt to changing demands or disruptions in supply quickly.

- Modular and reconfigurable manufacturing systems that can be quickly adapted to new tasks.

Workforce Adaptability:

- Emphasizing the importance of continuous learning, upskilling, and reskilling so that employees can adapt to changing technologies and processes.

- Promoting a culture of adaptability and innovation among employees.

Strategic Stockpiling:

- Having reserves of essential components or raw materials to ensure continuity in the face of supply chain interruptions.

Digital Tools for Predictive Analysis:

- Using artificial intelligence and big data analytics to predict potential disruptions based on various indicators, enabling industries to take preventive measures.

Collaboration and Information Sharing:

- Building partnerships with other businesses, governments, and institutions to share knowledge, resources, and strategies for dealing with disruptions.

Financial Preparedness:

- Ensuring businesses have financial buffers or strategies in place to weather economic downturns without massive layoffs or shutdowns.

Post-Disruption Analysis:

- After any disruption, conducting thorough analyses to understand its causes, effects, and the effectiveness of the response. Using this knowledge to refine and improve resilience strategies.

In essence, resilience in Industry 5.0 is about anticipating the unpredictable, preparing for the inevitable, and adapting to the unexpected. It’s about creating industries that are not just efficient but also robust and agile enough to navigate and thrive amidst challenges. As indicated earlier, our concept of Industry 5.0 is an open and evolving concept, providing a basis for further development of a collaborative and co-creative vision of the European industry of the future.

Nonetheless, we believe the core of Industry 5.0 can be defined as follows:

Industry 5.0 recognises the power of industry to achieve societal goals beyond jobs and growth to become a resilient provider of prosperity, by making production respect the boundaries of our planet and placing the wellbeing of the industry worker at the centre of the production process.

2. Asset & Maintenance Management in the Industry 5.0 timeframe

Industry 5.0 is the next stage of the industrial revolution that involves the integration of advanced technologies such as artificial intelligence (AI), machine learning (ML), and the internet of things (IoT) with humans in the workplace to manufacture and deliver goods that meet the demands of the highly-customized market. Characteristics of Industry 5.0 include value creation, customer centricity, sustainability, and collaborative robots or “cobots.” Industry 5.0 also includes components such as Automated Guided Vehicles (AGVs), 3D printing, and Augmented Reality (AR).

2.1 Asset Management and Maintenance Management in Industry 5.0:

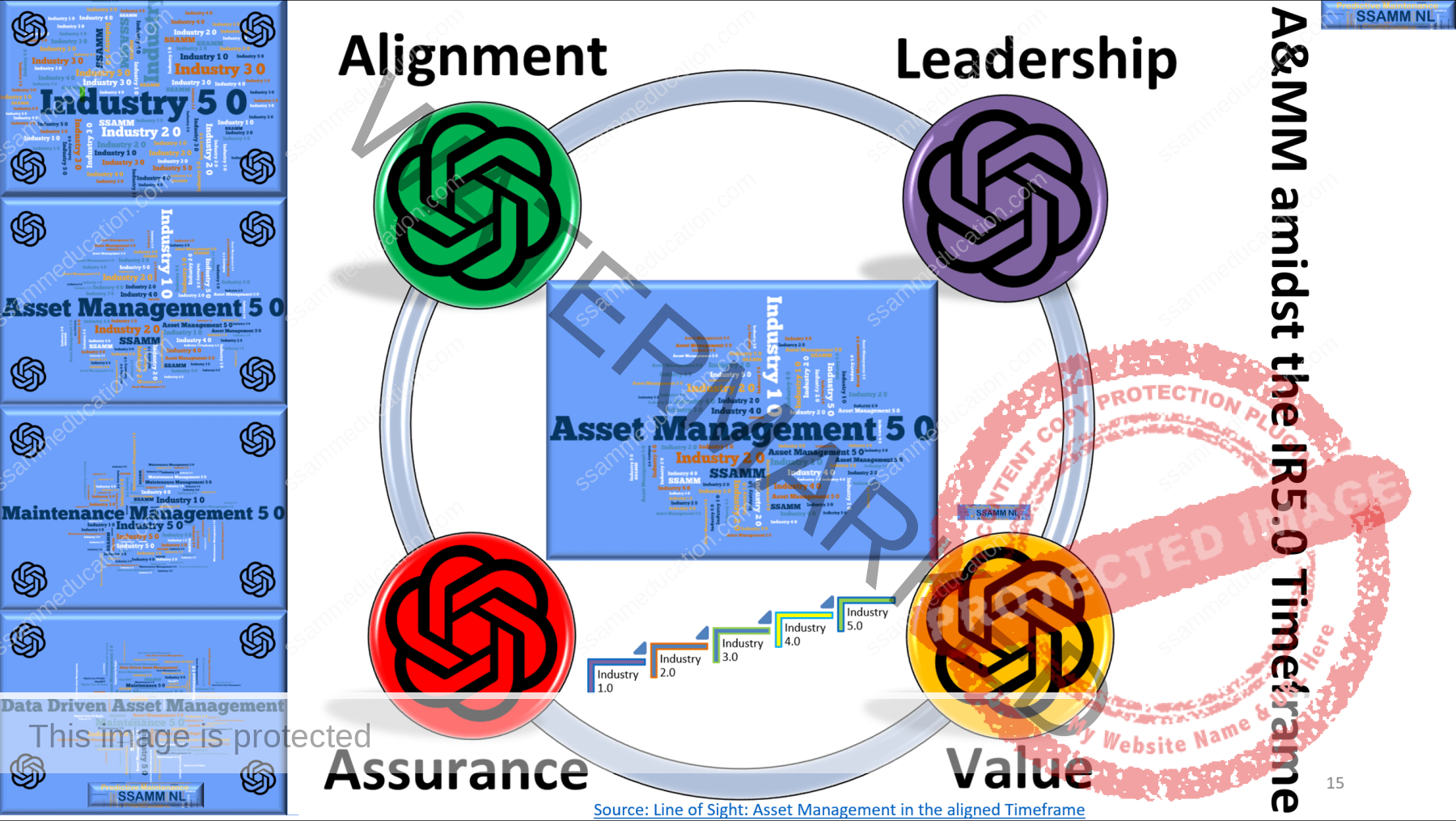

Asset management involves the systematic and coordinated activities and practices through which an organization optimally and sustainably manages its assets and asset systems. On the other hand, maintenance management involves the processes and activities required to keep equipment, machines and infrastructure in a safe and efficient operating state. In Industry 5.0, both asset and maintenance management play a more critical role in ensuring smooth and efficient operations. Integration of the two enhances a company’s ability to manage its assets effectively and develop a robust, sustainable maintenance management program.

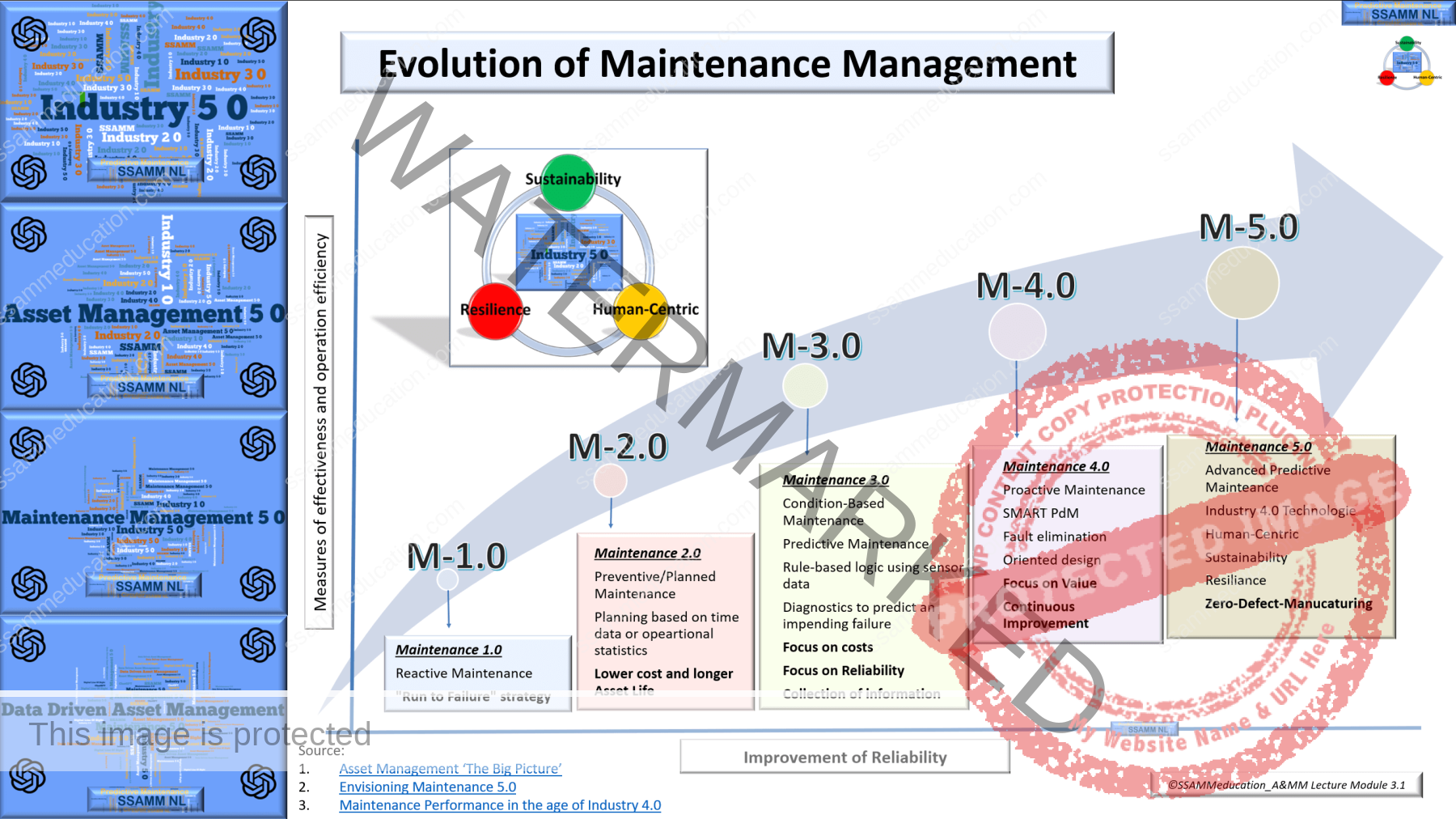

Click To Enlarge: Maintenance Management 5.0

2.2.1 Asset Management in Industry 5.0:

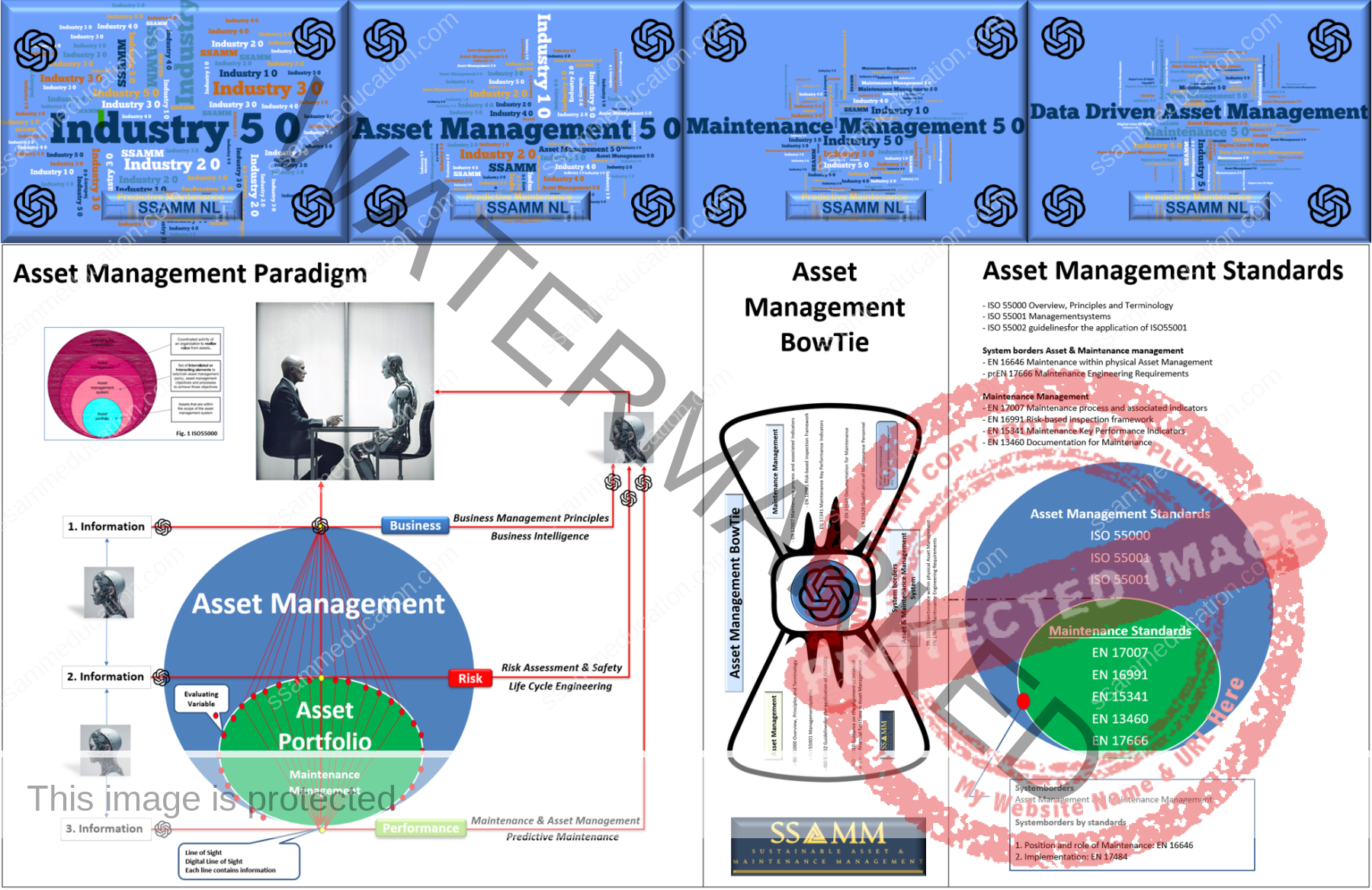

Asset management is an essential element of any industry, providing businesses with the necessary tools to optimise productivity and efficiently manage their assets. The ISO55000 standards have been developed as a global framework to ensure organisations meet optimal standards of asset management. However, with the introduction of Industry 5.0, the significance of these standards has become even more prominent. As a result, the ISO55001, ISO55002, and ISO55010 standards have been introduced to improve and develop industry-leading techniques for asset management. These standards have been designed to ensure that every organisation can deliver continuous improvement in reliability, performance, and risk management. By describing asset management using ISO55000, companies can optimise their assets and streamline their operational processes, delivering exceptional performance and results.

Industry 5.0 is the latest evolution of the manufacturing industry, where Asset Management and Maintenance Management are seamlessly connected with the help of DIN/EN 17666 and BS-EN16646 standards. This combination helps industries streamline their operation by bringing two crucial components together. With BowTie methodology connecting Asset Management and Maintenance Management, companies can easily identify risks and potential issues and prevent them from happening in the first place. This innovative approach also helps reduce resource costs, optimizes production and actively contributes to a sustainable future. As Industry 5.0 gains momentum, businesses are looking to embrace this new era of manufacturing to enhance their efficiency while reducing their carbon footprint.

In Industry 5.0, asset management is crucial and highly relevant. ISO55000, ISO55001, ISO55002, and ISO55010 standards are recognized for organizations wanting to implement disciplined asset management. Benefits of implementing asset management in Industry 5.0 include improved asset management processes, enhanced risk management, and increased financial performance. Additionally, the impact of Industry 5.0 on asset management practices can be seen in the increased use of predictive maintenance, which facilitates more accurate and timely identification of potential equipment breakdowns and failures, or other issues that could result in downtime.

2.2.1 Maintenance Management in Industry 5.0:

The need for efficient and timely maintenance operations in Industry 5.0 cannot be overstated. EN 17007, EN 16991, EN 15342, EN 13460, and EN 15628 standards provide guidelines for implementing rigorous maintenance management practices. Benefits of implementing such standards in Industry 5.0 include improved resource management, optimized equipment availability, and robust safety and environmental protocols. The impact of Industry 5.0 on maintenance management practices is pivotal in the shift from corrective or reactive maintenance systems towards more proactive or predictive maintenance systems.

Industry 5.0 has brought about significant advancements in the field of maintenance management. With the help of various standards such as EN 17007, EN 16991, EN 15342, EN 13460 and EN 15628, maintenance management has been redefined, revolutionized and streamlined. One of the most effective approaches to maintain this positive change is through the BowTie-based description of maintenance management. This approach involves the use of a visual risk assessment method, where the potential hazards and the preventive measures are represented by a bowtie-shaped diagram. By using this methodology, companies can clearly identify the potential risks involved, and take the necessary actions to mitigate them. This improves safety standards, enhances efficiency and reduces downtime in a cost-effective manner.

2.3 Connecting Asset Management and Maintenance Management:

Industry 5.0 is the latest evolution of the manufacturing industry, where Asset Management and Maintenance Management are seamlessly connected with the help of DIN/EN 17666 and BS EN 16646 standards. This combination helps industries streamline their operation by bringing two crucial components together. With BowTie approach connecting Asset Management and Maintenance Management, companies can easily identify risks and potential issues and prevent them from happening in the first place. This innovative approach also helps reduce resource costs, optimizes production and actively contributes to a sustainable future. As Industry 5.0 gains momentum, businesses are looking to embrace this new era of manufacturing to enhance their efficiency while reducing their carbon footprint.

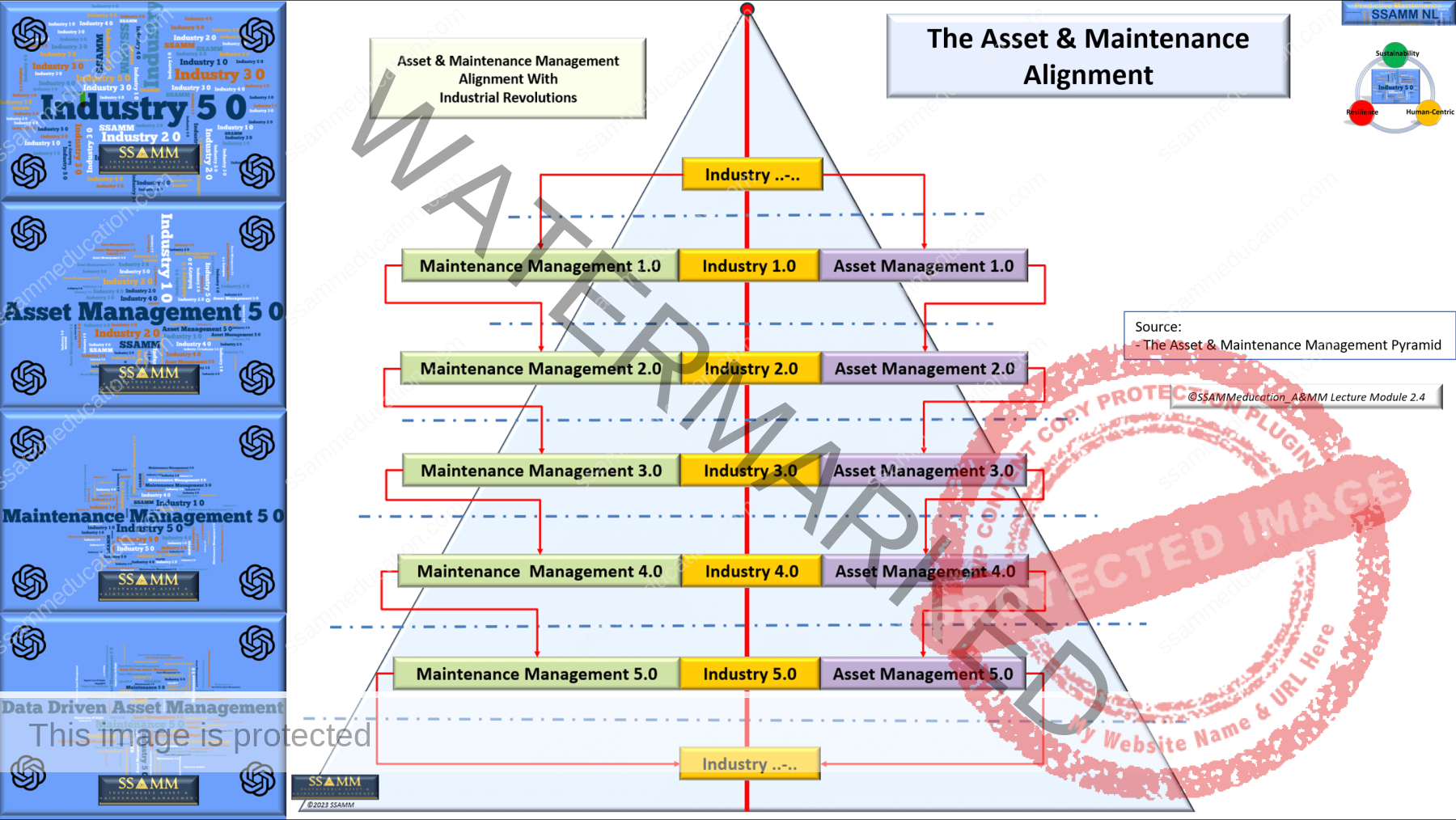

Click To Enlarge: Alignment of Industrial Revolutions

Click To Enlarge; The Asset Management BowTie

Connecting Asset Management and Maintenance Management is essential in Industry 5.0. DIN/EN 17666 and BS EN 16646 standards help organizations understand the interplay between the two. Integration of asset and maintenance management processes enhances the company’s ability to optimize its assets and effectively manage maintenance. Benefits of connecting the two include reduced costs, enhanced asset utilization, improved safety, reliability, and environmental performance.

2.4 Industry 5.0 and The Human Generations:

Each of the generations alive today has a unique relationship with technology, and this affects how they work and view work. Understanding the impact that Industry 5.0 will have on all human generations is of critical importance. Industry 5.0 can bridge the divide between generations by providing equal opportunities for all. It also fosters a positive working culture where all employees feel valued, respected, and essential in the organization’s success. Younger generations can also influence the integration of new technologies in the workplace and positively impact how value creation is achieved.

Click To Enlarge; Timeline Human Generations

Throughout history, innovations in technology and industry have fundamentally redefined human generations. From the Lost Generation and the Greatest Generation to the Baby Boomers, Generation X, Millennials/Generation Y, and Generation Z, each group has experienced the impact of the industrial revolutions that have shaped our world. Today, we find ourselves on the cusp of Industry 5.0, the latest evolution in manufacturing that builds on the advances of Industry 4.0 and emphasizes collaboration between humans and machines. In this context, it is important to understand how each generation has adapted to previous technological shifts, and what lessons we can learn as we enter this new era.

3. Impact of Industry 5.0 in the field of Asset & Maintenance Management

Industry 5.0 wil impact on the professions in the field of Asset Anad Maintenance Management like Maintenance Managemenr, Maintenance Engineers, Asset Managers, and Reliability Engineers. These professionals will need to adapt to the changing environment and acquire new skills and knowledge in areas such as data analytics, artificial intelligence, and automation. This transformation will not only benefit the companies but also create more opportunities for career growth for these professionals.

3.1 The Asset Managers

Regarding the ISO55000 stadards the impact for physical Asset Managers, for example, will be a shift from traditional asset management to strategic asset management. They will need to focus on increasing the lifespan of assets by integrating new technologies and processes in their maintenance strategies. For the Asset managares it demands a full understanding of the fundamentals of Asset Management in a ‘technical’envorionment’like the line of sight and descision making .

Asset Management professionals will also have to consider the environmental and social impacts of their decisions in accordance with the principles of sustainable development. This will require a more holistic approach to asset management, taking into account not just financial aspects but also societal and environmental considerations.

Furthermore, Industry 5.0 will bring about a shift towards asset optimization, where assets are continuously monitored and analyzed in real-time to identify potential issues before they occur. This proactive approach will minimize downtime and maximize asset performance, resulting in significant cost savings for companies.

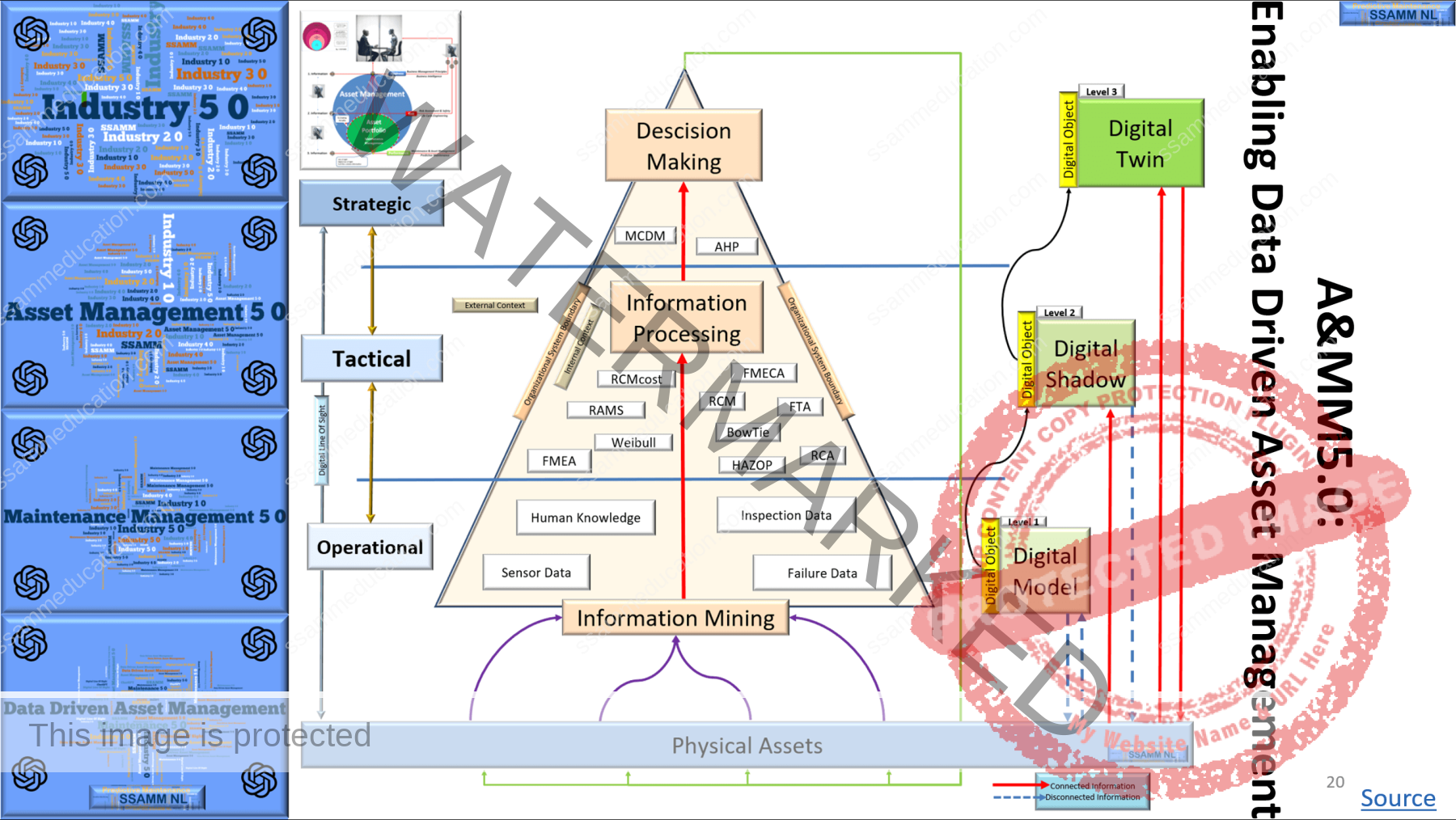

Click To Enlarge: IR5.0 enabler of Data Driven Asset Management

Click To Enlarge; Digital Twin: Deepening the subject

3.2 The Maintenance Manager

The role of Maintenance Managers in the Industry 5.0 is more than turbulent . They are responsible for overseeing the entire maintenance process, ensuring that all standards and protocols are followed and maintained. In addition to this, Maintenance Managers also need to stay updated with the latest maintenance techniques and technologies in order to effectively manage their operations. With the rapid advancements in technology, it has become essential for Maintenance Managers to constantly upgrade their skills and knowledge.

Furthermore, Industry 5.0 has also brought about a shift towards data-driven maintenance management. This involves the use of advanced data analytics tools and techniques to monitor equipment health, predict potential failures, and schedule maintenance activities accordingly. By implementing these practices, companies can reduce downtime, optimize resources and save costs in the long run.

3.3 The Maintenance Engineer

For Mainteance engineers regarding the EN17666 in the Industry 5.0 timeframe , it is crucial to have a clear understanding of the standard and its requirements. This includes knowledge on asset management, maintenance strategies, risk assessment methods, and continuous improvement processes. Additionally, Maintenance Engineers should also have good communication skills as they will be working closely with other departments and external contractors.

It is important for companies to invest in training and development programs for their Maintenance Managers and keep them aligned with the technical developments in the industry. This not only helps to improve their skills and knowledge but also boosts morale and motivation, leading to better job performance.

Click To Enlarge: The Potential Failure Curve – The Milk Approach

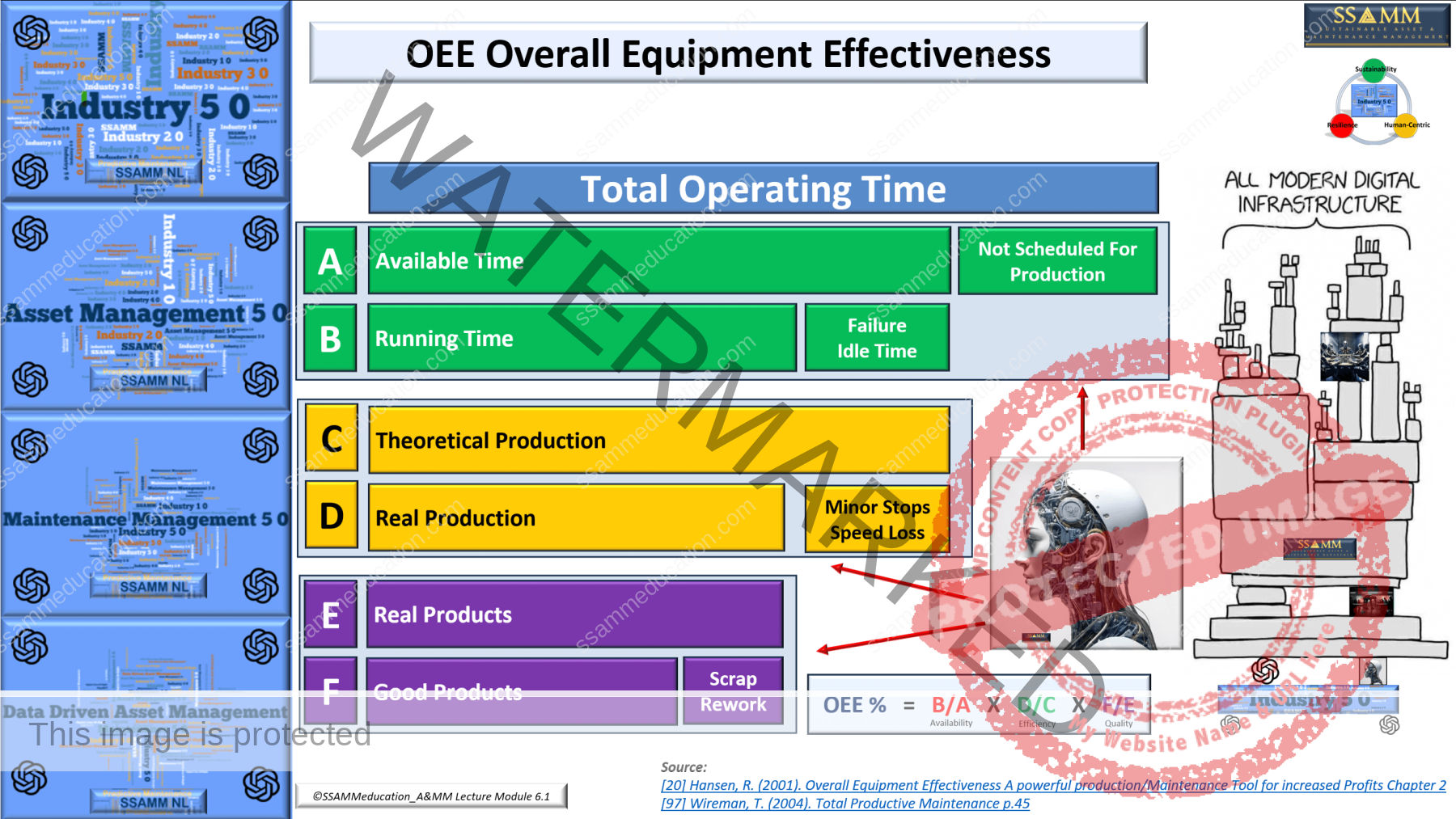

Click To Enlarge; OEE and IR5.0: The Impact of A.I.

3.4 The Reliability Engineer

For the reliability engineers Industry 5.0 will be the enabler of information and data -driven decision-making. With the use of advanced technologies such as IoT, AI and machine learning, reliability engineers will have access to real-time data on equipment health and performance. This allows them to proactively identify potential issues and make informed decisions for optimizing maintenance strategies. Moreover, reliability engineers will also play a crucial role in implementing and monitoring the effectiveness of data-driven maintenance practices.

In addition to technical skills, it is important for reliability engineers to have a strong understanding of business processes and objectives. This helps them to align their maintenance strategies with the overall goals of the company and prioritize critical equipment accordingly. It is also essential for reliability engineers to have good communication skills as they will be working with cross-functional teams and communicating data-driven insights to management.

Furthermore, reliability engineers must possess strong project management skills in order to successfully implement new technologies and processes. This involves coordinating with different departments, managing timelines and budgets, and ensuring the smooth integration of new systems into existing operations.

4. The Asset Management System in the Indusrty 5.0 timeframe.

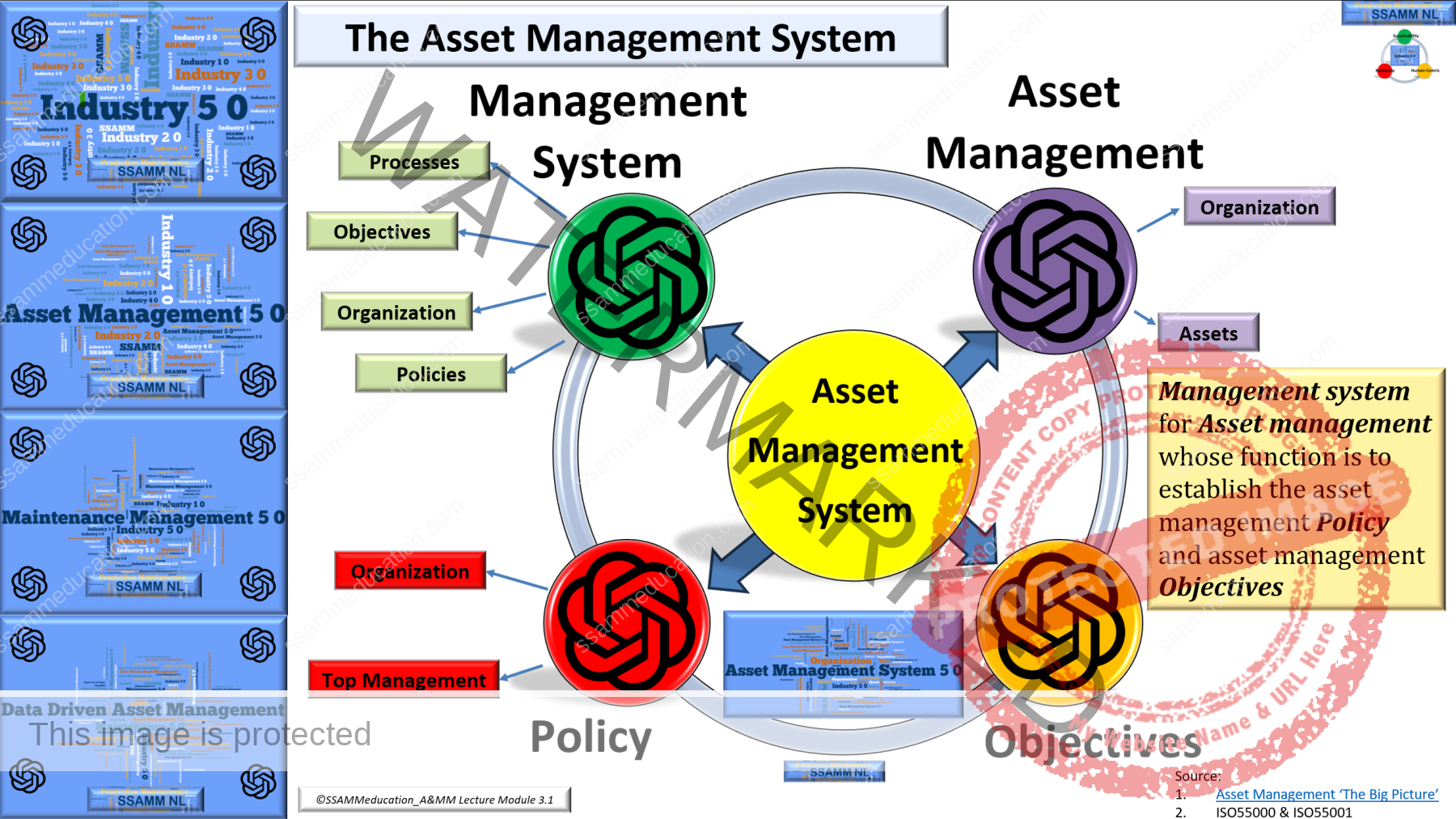

According to ISO55000 paragraph 3.4.3, an Asset Management System (AMS) is a management system for asset management which functions to establish the asset management policy and objectives of an organization. This system serves as a framework that guides the organization in effectively managing their assets throughout their lifecycle.

Furthermore, ISO55001 paragraph 4.3 states that the organization is responsible for determining the boundaries and applicability of their AMS in order to establish its scope. This scope must be aligned with the Strategic Asset Management Plan (SAMP) and the asset management policy, ensuring a cohesive approach to asset management within the organization.

In simpler terms, an AMS is a structured approach to managing assets which aims to balance the financial, operational, and societal aspects of asset management. It serves as a crucial tool for organizations in achieving their objectives while also promoting sustainable and responsible practices. In the following sections, we will explore the role of AMS in Asset & Maintenance Management and how it contributes to achieving a balance between technological advancements and social responsibility.

4.1 Benefits of an Asset Management System

Implementing an AMS can bring numerous benefits to an organization, ranging from operational efficiency to improved decision-making. Here are some key advantages that come with adopting an AMS:

4.1.1 Improved Overall Performance and Cost Savings

By effectively managing assets through an AMS, organizations can improve their overall performance and reduce costs. An AMS allows for better tracking and monitoring of assets, identifying potential issues or inefficiencies early on. This proactive approach leads to timely maintenance interventions, minimizing downtime and increasing asset lifespan.

Moreover, an AMS also enables data-driven decision-making by providing valuable insights into asset performance, usage patterns, and maintenance costs. This allows organizations to optimize their asset management strategies, resulting in cost savings and improved efficiency.

4.1.2 Enhanced Safety and Compliance

An AMS can also contribute to improving safety within an organization by ensuring that assets are maintained and operated in compliance with safety regulations. With real-time tracking of asset conditions and performance, potential safety hazards or non-compliance issues can be identified early on and addressed promptly.

Furthermore, regulatory compliance is becoming increasingly important for organizations to avoid penalties and maintain their social responsibility. An AMS can assist in meeting compliance requirements by providing accurate and up-to-date asset data, making audits and inspections smoother and more efficient.

4.1.3 Better Resource Allocation

An AMS also enables organizations to better allocate resources by having a clear overview of assets’ condition and maintenance requirements. By prioritizing assets that require immediate attention, organizations can minimize downtime and optimize their workforce’s productivity.

Additionally, an AMS allows for better planning of resource allocation by providing data on asset usage patterns. This information can be used to schedule preventive maintenance during periods of low usage, minimizing disruption while ensuring assets remain in optimal condition.

4.1.4 Improved Customer Satisfaction

Effective asset management also leads to improved customer satisfaction. By ensuring that assets are well-maintained and available for use, organizations can provide better service to their customers. This is particularly crucial for businesses that rely on equipment or machinery to deliver products or services.

With an AMS, organizations can proactively identify potential issues with assets and address them before they impact customers. This results in reduced downtime and improved overall customer experience.

Furthermore, an AMS can also improve transparency and communication with customers. By providing real-time data on asset availability and maintenance schedules, organizations can keep customers informed and manage their expectations effectively.

4.1.5 Summarising the AMS.

Implementing an Asset Management System offers numerous benefits for organizations of all sizes. From cost savings to improved compliance and customer satisfaction, an AMS can help organizations streamline their asset management processes and optimize their operations.

To reap the full benefits of an AMS, it is essential to choose a solution that aligns with your organization’s unique needs and goals. With the right AMS in place, organizations can gain better control over their assets and enhance their overall performance and success. As technology continues to advance, investing in an AMS is becoming increasingly crucial for organizations looking to stay competitive and achieve long-term success. So, if you haven’t already, now is the time to start exploring your options and implement an effective Asset Management System for your organization.

Keep in mind, asset management is not just about keeping track of assets; it’s about maximizing their value and utilizing them effectively to drive business growth. By adopting an AMS, organizations can transform their asset management processes and unlock new opportunities for growth and success.

Click To Enlarge: The Asset management System in the IR5.0 timeframe

Click To Enlarge; The Digital Elephant In the Room

4.2 Asset Management Systems in the Industry 5.0 timeframe

Industry 5.0, also known as the “Human-Centric Industry”, has brought about significant changes in the world of asset management systems. With a focus on resilience, human-centricity, and sustainability, Industry 5.0 aims to create a more balanced and harmonious relationship between humans and machines.

This shift towards a more collaborative approach to technology has had a profound impact on asset management systems. It has emphasized the importance of utilizing assets in a sustainable and responsible manner, considering their impact on both people and the environment.

In addition to sustainability, Industry 5.0 also places a strong emphasis on resilience in asset management. With the increasing frequency of natural disasters and other unforeseen events, organizations need to have robust asset management systems in place to ensure business continuity and minimize disruptions. This means not only having backups and redundancies but also implementing proactive measures to mitigate risks and quickly recover from any incidents.

But perhaps the most significant impact of Industry 5.0 on asset management systems is its human-centric approach. In this new era, technology is not seen as a replacement for humans, but rather a tool to enhance their capabilities. Asset management systems are now designed with the end-user in mind, keeping their needs and preferences at the forefront. This shift towards a more human-centric approach has led to increased employee satisfaction, productivity, and overall business success.

Moreover, Industry 5.0 has also brought about a change in the way asset management systems are implemented and utilized. With a greater focus on collaboration and communication between humans and machines, organizations are now leveraging technologies such as artificial intelligence, machine learning, and Internet of Things to optimize their asset management practices. This not only allows for better decision-making but also enables organizations to predict and prevent potential issues before they even occur.

4.2.1 The impact of A.I. on Asset Management Systems

Industry 5.0 and its integration of artificial intelligence (AI) have greatly impacted the current and future workforce in a multitude of ways. On one hand, it has brought about numerous benefits such as increased efficiency, accuracy, and productivity. AI-powered asset management systems are able to process large volumes of data much faster than humans, allowing for better decision-making and optimization of resources. This not only saves time and money for organizations but also allows employees to focus on more value-adding tasks.

On the other hand, the use of AI in Industry 5.0 has also raised concerns about job displacement and the need for upskilling or reskilling. With machines taking over routine and repetitive tasks, some jobs may become obsolete while new roles requiring advanced technical skills may emerge. This creates a demand for professionals to constantly upskill and adapt to the changing landscape of the industry.

Furthermore, AI also has the potential to perpetuate biases and inequalities if not properly monitored and regulated. It is important for organizations to consider ethical implications and ensure that AI systems are designed and used responsibly, taking into account diversity, fairness, and privacy.

However, despite these challenges, the impact of Industry 5.0 and AI on the workforce is undeniable. It has opened up new opportunities for innovation and growth, providing professionals with vast potential for career development and advancement. With AI taking over mundane tasks, employees have more time to focus on creative problem-solving and critical thinking, adding value to their work.

For individuals, it is crucial to embrace lifelong learning and continuously adapt to the evolving technological landscape. This will not only ensure job security but also pave the way for personal and professional growth.

Overall, Industry 5.0 and AI present a transformative journey towards a more efficient, innovative, and inclusive future. By harnessing the power of technology while keeping ethical considerations in mind, we can build a world where humans and machines work together towards creating a better tomorrow. So let us embrace this exciting era of Industry 5.0 and AI, and strive to make the most out of its potential for the betterment of society as a whole. Let’s not be afraid of change, but instead, let’s welcome it with open arms and use it to create a better world for ourselves and future generations. Let’s work together to build a future where technology and humanity coexist in harmony, driving progress and prosperity for all.

4.3 The impact on Asset Managers, Maintenance Engineers and Maintenance Managers withing the AM-System

In the context of Industry 5.0, AI has a significant impact on the Asset Management System. With the integration of AI technology, asset management systems are becoming more efficient, innovative and inclusive than ever before.

For professionals in the field of asset management, such as asset managers, maintenance engineers and maintenance managers, this means a shift towards a more strategic role. AI-powered asset management systems are able to analyze vast amounts of data and provide valuable insights, enabling professionals to make more informed decisions and take proactive measures. This not only improves the overall efficiency of asset management processes but also reduces the potential for human error.

Click to enlarge: The Line Of Sight

In addition, AI allows for predictive maintenance, where machines can detect potential issues before they occur and schedule maintenance accordingly. This leads to cost savings, as well as increased productivity and reliability of assets. A.I. also enables asset managers to optimize the usage of assets by identifying patterns and trends, which in turn leads to better resource allocation. This is particularly important in the context of Industry 5.0, where data-driven decision making is crucial for success.

Moreover, the use of AI in asset management systems allows for a more inclusive approach, as it can cater to different types of assets and industries. This means that professionals in asset management can expand their expertise and work with a wider range of clients.

Overall, the impact of AI on the Asset Management System is transforming the profession for asset managers, maintenance engineers and maintenance managers. It empowers them with advanced tools and capabilities to streamline processes, increase efficiency, and make more informed decisions. This not only benefits businesses in terms of cost savings and productivity but also enhances the overall quality of asset management services.

Furthermore, as AI continues to evolve and become more advanced, it has the potential to revolutionize the field of asset management even further. With increased automation and machine learning capabilities, professionals will be able to predict maintenance needs and optimize asset usage in real-time, making the entire process more efficient and effective.

But beyond its practical applications, the use of AI in asset management also has a larger impact on society. As industries become more data-driven and technology-centric, there is a growing need for professionals who are skilled in managing these systems. This opens up new opportunities for individuals to acquire these skills and enter the field of asset management.

In addition, the use of AI also promotes sustainability in asset management. By optimizing asset usage and predicting maintenance needs, businesses can reduce their environmental impact by decreasing energy consumption and minimizing waste.

Therefore, it is clear that the integration of AI in asset management systems not only benefits businesses but also has a positive impact on society as a whole. As technology continues to advance, it is crucial for professionals in the asset management industry to embrace and adapt to these innovations in order to stay competitive in a rapidly evolving market. With AI-powered tools and techniques at their disposal, they have the potential to revolutionize the way assets are managed, leading to a more efficient, sustainable, and prosperous future.

5. Reference Articles

European Commission

Directorate-General for Research and Innovation

Directorate F — Prosperity

Unit F.5 — Industry 5.0

5.1 Industry 5.0 Related

- Maturity assessment for Industry 5.0: A review of existing maturity models

- Industry 5.0: Past, Present and Near Future

- IR5.0 Human-Centric underpinned with 2022 Industrial Maintenance study

- Human in the loop: Industry 4.0 vs. Industry 5.0: Co-existence, Transition, or a Hybrid

- Industry 5.0 further explained

- Industry 5.0 and Society 5.0: Comparison, complementation and co-evolution

- Outlook on human-centric manufacturing towards Industry 5.0

- Maintenance 5.0: Towards a Worker-in-the-Loop Framework for Resilient Smart Manufacturing

- Industry 5.0: Prospect and retrospect

- Industry 5.0 definitions

- Be informed…. we are already in the Industry 5.0 timeframe

5.2 IR4.0 & IR4.0 Readiness

- An Industry 4.0 readiness Assessment tool

- Intelligent warehouse in Industry 4.0

- Maintenance Performance in the Age of Industry 4.0

- Simulating dynamic RUL based CBM scheduling

- Maintenance Analytics – The New Know in Maintenance

- Rethinking Maintenance Terminology for an Industry 4.0 Future

- Maintenance optimization in industry 4.0; Strategies, Information and the Reversed Data Pyramid

- An RUL-informed approach for Life Extension of high-value assets: Overview of LE practice

- Lean Maintenance 4.0: implementation for aviation industry

- Developing prescriptive maintenance strategies in the aviation industry

- Development of flexible Predictive Maintenance systems in the context of industry 4.0: the implementation framework

5.3 Digital Twin Related

- Reflection: Disruptive Innovation Asset & Maintenance Management

- Collecting Real-Time Data for Predictive Maintenance

- Lean Maintenance 4.0: implementation for aviation industry

- A digital twin-based decision analysis framework for operation and maintenance of tunnels

- Digital building twins and blockchain for performance-based (smart) contracts

- IoT for predictive assets monitoring and maintenance: An implementation strategy

- About auditing in the field of Asset Management

- A Digital Twin Design for Maintenance Optimization

- The difference between Machine Learning(ML) and Deep Learning (DP)

- Digital Twin Definitions: a time perspective

- Definition Digital Twin

- Approach for a Holistic Predictive Maintenance Strategy by Incorporating a Digital Twin

- Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning

- Advances of Digital Twins for Predictive Maintenance

- The 250 classifications of Digital Twin technology

5.4 Maintenance Management

- Decision-based framework for Predictive Maintenance Technique selection in Industry 4.0

- Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning

- Recent advances and trends of predictive maintenance from data driven machine prognostics perspective

- Data-driven decision-making for equipment maintenance: Data-driven RCM

- Toward cognitive predictive maintenance: A survey of graph-based approaches

- A deep learning predictive model for selective maintenance optimization

- Inspection schedule for prognostics with uncertainty management

- Development of Digital Twin for Intelligent Maintenance of Civil Infrastructure

- Risk Based Inspection Framework part of evolutions in Maintenance Management; Framework and Process

- KSPMI: A Knowledge-based System for Predictive Maintenance in Industry 4.0

- Sharping the mind: Find The Sweet spot

- The Bathtub Curve Fallacy

- The framework for data-driven maintenance planning and problem-solving in maintenance communities

- The Maintenance Body of Knowledge

- Decision Framework for Predictive Maintenance Method Selection

- Maintenance Engineering defined

- The Maintenance 5.0 Framework

- The Maintenance 5.0 Cycle

5.5 Interpretation Article’s

- Line of Sight: Asset Management in the aligned timeframe

- Interpretation Figure 1 ISO55000

- The elephant in the room

- Asset & Maintenance Management amidst the Industry 5.0 timeframe

- Revised A&MM The Big Picture

- Article IR5.0 Human-Centric

- Explaining Predictive Maintenance using the KISS-Principle

- Asset Management 5.0: Balancing Risk, Performance and Value with IR5.0

- Food for Thoughts: ChatGPT in the field of Asset & Maintenance Management.

5.6 Additional Pages To Consult

- Sustainable Asset Management

- The Maintenance Engineer

- The Maintenance Manager

- The Asset Manager

- Industry 5.0

- Circular Asset Management

- Asset Condition Monitoring

- Asset & Maintenance Management 5.0 Implementation

- The SSAMM Academy

Tags: Assetmanagement, conference paper, Industry4.0, Industry5.0