Publication reference

Title: The Maintenance Framework

Author: Benjamin Stoker

Publisher: SSAMM (Click Here)

Publication platform: SSAMM Academy – ssammeducation.com

ISBN/EAN: 978-90-8339-896-9

This restricted web article provides an overview and selected extracts from the publication The Maintenance Framework (ISBN/EAN 978-90-8339-896-9). It is made available exclusively to registered SSAMM Academy clients as part of their personal, non-transferable licence.

© 2024 Stoker / SSAMM. All rights reserved.

This content is provided under a personal, non-transferable licence. Unauthorised sharing of logins, screenshots, files or copies (in whole or in part) is not permitted

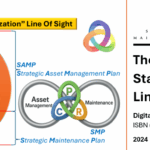

The framework stresses the distinction between the SAMP as a dynamic, multidisciplinary process and the Strategic Asset Management Plan as its formalised output, and argues that maintenance must be structurally embedded in this process to avoid static, compliance-driven planning detached from operational reality.

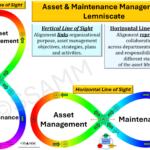

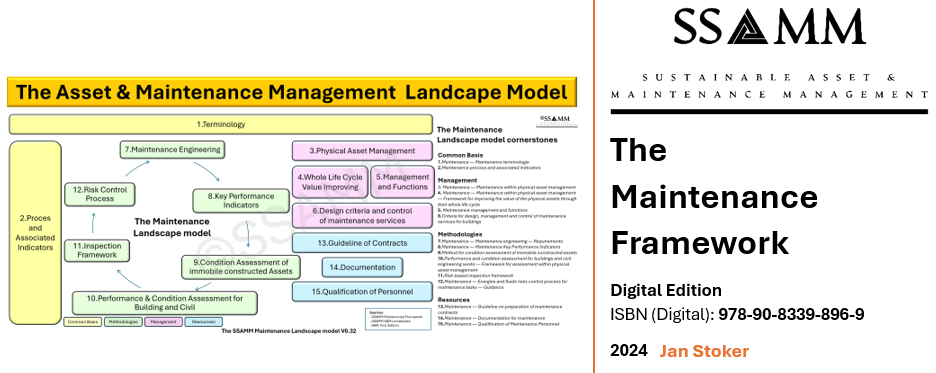

Architecturally, the framework is anchored in the Asset & Maintenance Management Lemniscate, which creates a continuous horizontal and vertical “line of sight” between the IAM 10-box Asset Management Model (strategic side) and the 15-box Maintenance Landscape Model (operational side). Within this landscape, maintenance is organised into four segments—Common Basis, Management, Methodologies and Resources—providing the conceptual and practical backbone for modern Maintenance Management.

EN 17007 further refines this architecture by categorising maintenance into three process families (Management, Realization and Support) comprising 16 core processes that govern how performance, risk and cost are managed across the life cycle.

The SSAMM Maintenance Assessor Tool, built on EN 17007, provides a structured maturity scan of the 16 processes, enabling organisations to benchmark, visualise and systematically improve their maintenance capability.

Together, these elements present maintenance as a normative, standards-based and future-oriented discipline at the core of Asset Management and Industry 5.0.

Application for The Maintennance Framework inlog- Concept draft extending A&MM Lemniscate

- Fisrst draft 3 ocktober2024

- Updated 17 August 2025

- Published 9 September 2025

- Published SSAMM Social Media platforms October 2025

Maintenance Fundamentals SAM, First Edition Keynote Āpōpō Congres 2026 Follow Sustainable Asset Management for latest updates

Countdown SSAMM Academy Module 1

Explore the SSAMM Academy Asset Management and Maintenance Management courses.

Click Here for the Smart information page

Author: Ing. Jan Stoker MSc. MEng. AMCP. CFAM. Follow Jan Stoker

1. Maintenance as a Strategic Function in Industry 5.0

In the context of Industry 5.0, maintenance is no longer a purely technical support function aimed at “keeping things running”. It is reframed as a strategic enabler of value creation, resilience and sustainability. Industry 5.0 combines advanced digital technologies (AI, digital twins, IoT, advanced analytics) with a human-centric perspective, in which people, systems and data work together to achieve reliable, safe and sustainable performance over the entire asset life cycle.

At the heart of this integration lies the distinction between the Strategic Asset Management Process (SAMP) and the Strategic Asset Management Plan. The process is a continuous, multidisciplinary mechanism that translates organizational objectives into asset strategies and governance arrangements. The plan is the documented output of that process. The Maintenance Framework stresses that maintenance must be structurally embedded in the SAMP, otherwise the plan risks becoming a static document disconnected from operational reality.

2. The Asset & Maintenance Management Lemniscate and the Maintenance Landscape

The Asset & Maintenance Management Lemniscate provides the architectural backbone for connecting strategic asset management and operational maintenance. It visualizes a continuous loop—horizontal and vertical “lines of sight”—between:

- the IAM 10-box Asset Management Model on the strategic, left-hand side, and

- the Maintenance 15-box Landscape Model on the operational, right-hand side.

On the left, the IAM 10-box model structures themes such as policy, strategy, asset information, risk and lifecycle delivery. On the right, the Maintenance Landscape translates those themes into concrete maintenance planning, execution and improvement activities.

The Maintenance Landscape is organized into four segments that together form the common architecture for maintenance in the organization:

- Common Basis – shared standards, definitions, terminology and performance measures (e.g. EN 16646, EN 17485, ISO 55000). This creates a common language and reference frame for maintenance across departments.

- Management – policies, strategies, governance structures, budgets, risk assessments and performance monitoring for maintenance, guided by standards such as EN 17007 and EN 17948.

- Methodologies – the practical maintenance strategies and techniques (preventive, predictive, condition-based, corrective) that deliver the intended performance and risk profile.

- Resources – people, tools, spare parts, digital systems and infrastructures needed to execute maintenance effectively and sustainably.

The Lemniscate ensures that objectives and constraints defined at the strategic level (e.g. availability targets, sustainability ambitions, risk thresholds) are systematically translated into these four segments, and that operational data and experience flow back to inform strategy. Industry 5.0 technologies amplify this feedback loop by enabling real-time monitoring, predictive insights and more precise decision-making across the entire Maintenance Landscape.

Click to enlarge

3. The EN 17007 Maintenance Process Framework: Management, Realization, Support

The European standard EN 17007 provides the process-oriented core of the Maintenance Framework. It structures maintenance into three interdependent process families:

- Management processes – the strategic and tactical functions that align maintenance with organizational objectives. These include defining maintenance policies, setting performance targets, organizing roles and responsibilities, planning budgets and driving continuous improvement. Within the Lemniscate, these processes form the decision-making loop that regularly re-evaluates maintenance strategies using lifecycle data and risk insights.

- Realization processes – the execution of maintenance in the field. This covers preventive maintenance (PRV), corrective maintenance (COR), improvement actions. (IMP) and combined preventive/corrective activities (ACT). These processes are where asset performance is actually delivered and where the Asset Management Bow-Tie becomes highly relevant:

- On the left side of the Bow-Tie, preventive measures reduce the likelihood of failures.

- On the right side, corrective and mitigative actions limit the consequences when failures occur

- Support processes – the logistical, infrastructural, informational and financial backbone that enables management and realization. EN 17007 identifies a set of core support processes, including documentation (DOC), infrastructure (IST), maintenance requirements in design (MRQ), spare parts (SPP), tools and information systems (TOL), human resources (RES), health–safety–environment (HSE), budgeting (BUD), data and analysis (DTA) and optimization (OPT).

Together, these 16 processes form a system of maintenance rather than a loose set of activities. They make it possible to coordinate governance, execution and support functions in a transparent, auditable way that is fully integrated with the Asset Management System.

4. Maintenance Engineering Across the Asset Life Cycle: Maintainability and Circularity

The Maintenance Framework extends beyond operations by situating maintenance engineering across all asset life cycle stages—concept, development, realization, utilization and disposal/transition—in line with standards such as EN 17666 and EN-IEC 60760-2.

Two principles are central here:

- Maintainability – designing assets in such a way that maintenance can be carried out efficiently, safely and predictably (e.g. accessibility, modularity, standardized components, clear procedures).

- Circularity – designing and managing assets for reuse, refurbishment, remanufacture and recycling, thereby reducing waste and environmental impact.

In the concept and development stages, maintenance engineers use tools such as the Lemniscate and digital twins to evaluate design options against maintainability and circularity criteria. Decisions on materials, configurations and interfaces are taken with long-term maintenance and circular economy objectives in mind.

During realization and commissioning, maintainability and circularity principles are verified in the as-built system; documentation, training and digital support tools (including AR/VR) are prepared so that operations teams can execute maintenance safely and effectively.

In the utilization stage, the Maintenance Framework supports predictive, data-driven maintenance execution and continuous optimization of schedules, methods and spare parts. Circularity is operationalized by extending asset life, refurbishing components and minimizing waste.

Finally, in the disposal/transition stage, maintenance engineering underpins responsible decommissioning, systematic end-of-life assessments and the recovery of materials and components. Lessons learned are fed back into the next asset generation, closing the loop and strengthening Maintenance 5.0 as a learning, circular practice.

5. Measuring and Advancing Maintenance Maturity: The SSAMM Maintenance Assessor Tool

To move from concept to implementation, organizations need a way to assess the maturity of their maintenance processes and to identify targeted improvement priorities. The SSAMM Maintenance Assessor Tool: Maintenance Process fulfils this role.

Built directly on EN 17007 and related standards (EN 17948, EN 16991, EN 15628, EN 17666), the tool evaluates the 16 core maintenance processes across the three families—Management, Realization and Support—and visualizes their maturity in a radar diagram. This provides:

- a structured baseline of the current maintenance system,

- insight into strengths, weaknesses and inconsistencies,

- a reference for benchmarking against best practice, and

- a roadmap for process-level improvement and digitalization.

Within the Asset & Maintenance Management Lemniscate, the Assessor Tool supports both horizontal integration (linking maintenance with operations, finance, supply chain and sustainability) and vertical integration (linking strategic objectives with day-to-day execution). It makes explicit where gaps exist between strategic intent (e.g. Industry 5.0 ambitions, circular economy, risk appetite) and the actual maturity of maintenance processes.

In this way, the maintenance function becomes an explicit, measurable capability within the Asset Management System—one that can be designed, governed and improved with the same rigor as any other strategic function.

Concluding Perspective

The Maintenance Framework positions maintenance as a normative, standards-based and future-oriented discipline at the heart of Asset Management and Industry 5.0. It combines:

- the architectural integration of SAMP, the Lemniscate and the Maintenance Landscape,

- the process rigor of EN 17007 and related CEN/TC 319 standards,

- a life-cycle perspective on maintainability and circularity, and

- a maturity-oriented approach via the SSAMM Maintenance Assessor Tool.

Taken together, these elements show how maintenance can evolve from a perceived cost centre into a strategic, data-driven and human-centric capability that safeguards reliability, reduces risk, enables circularity and strengthens organizational resilience.

This summary sketches the main contours. The full publication elaborates the 15-box Maintenance Landscape, details the 16 EN 17007 processes, explains the Asset Management Lemniscate and Bow-Tie models, and illustrates how organizations can apply these concepts in practice to build a robust, Industry 5.0-ready Maintenance Management function.

Tags: Newsletter 1