In his ‘Learning Journey’ of defining Asset & Maintenance Management, lecturer/Researcher Jan Stoker of SSAMM write his finding and insights during this journey. Started in 2013 with his research, one of his goals is to understand Asset & Maintenance Management within the ISO55000 framework. Currently, his main goal is to describe and define Asset Management 5.0 based on this article. Check the related article’s on this page.

concept 12 December 2022

Updated 13 April 2023 5.0

Published 2 August 2023 IR-5.0 integration

Updated 3 September added Maintenance Management 5.0

Updated 29 Octoberadded added Maintainabiity

- Industry 5.0: Deepening The Subject

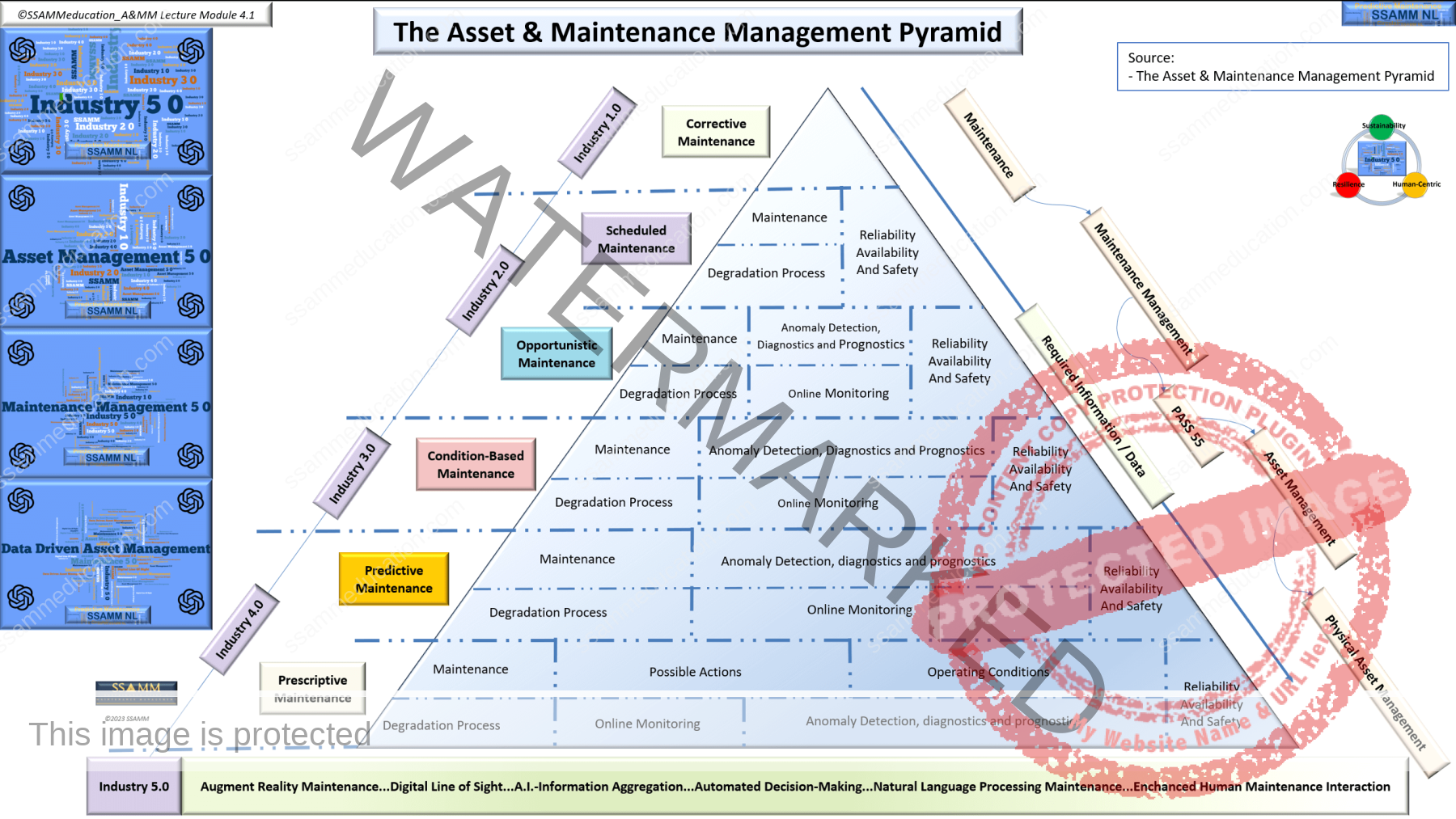

- The Asset & Maintenance Management Pyramid

- The Digital Line of Sight: Deepening the subject

- Maintenance Management: Deeppening the subject

- Digital Twin: Deepening the subject

- The Asset Management BowTie

- Conference Article

- Article IR5.0 Human-Centric

- The IR5.0 elephant in the room

- Decision-making with AI

- AM 5.0: Balancing Risk, Performance and Value

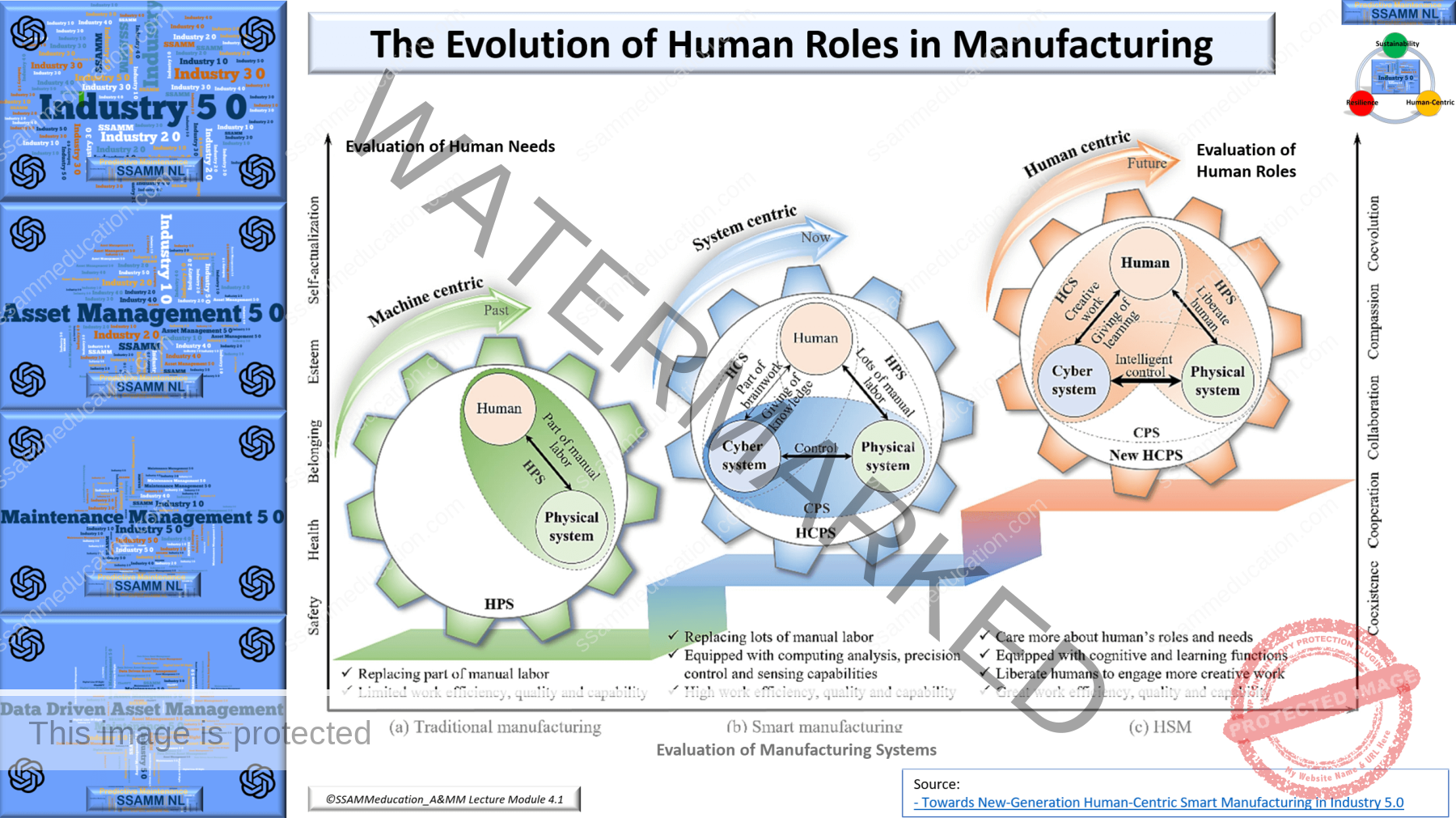

The chronological tandem of Maintenance Management paradigms and industrial revolutions encapsulates the inherent narrative of evolving technological endeavors meeting operational exigencies. As Industry 1.0 brought forth the advent of mechanized production powered by water and steam, Maintenance 1.0 emerged in response, primarily characterized by reactive measures to keep the rudimentary machines running. The essence of maintenance was simplistic – fix when broken, without a structured approach or foresight. With Industry 2.0, the focus pivoted towards mass production and assembly lines, giving birth to Maintenance 2.0, which introduced preventive maintenance into the industrial vocabulary. This was the genesis of routine checks and basic planning aimed at minimizing unplanned downtimes, hence beginning to sketch a more organized picture of maintenance. As the digital waves of Industry 3.0 started to make their mark with automation and early digital control systems, Maintenance 3.0 took a leap towards predictive maintenance. It harnessed emerging data analytics to forecast potential issues, endeavouring to mitigate them before they could disrupt the production flow, a stride towards proactive asset management. Industry 4.0 opened a new chapter with the marriage of cyber-physical systems, IoT, and big data analytics, wherein Maintenance 4.0 embraced real-time monitoring, and proactive maintenance strategies.

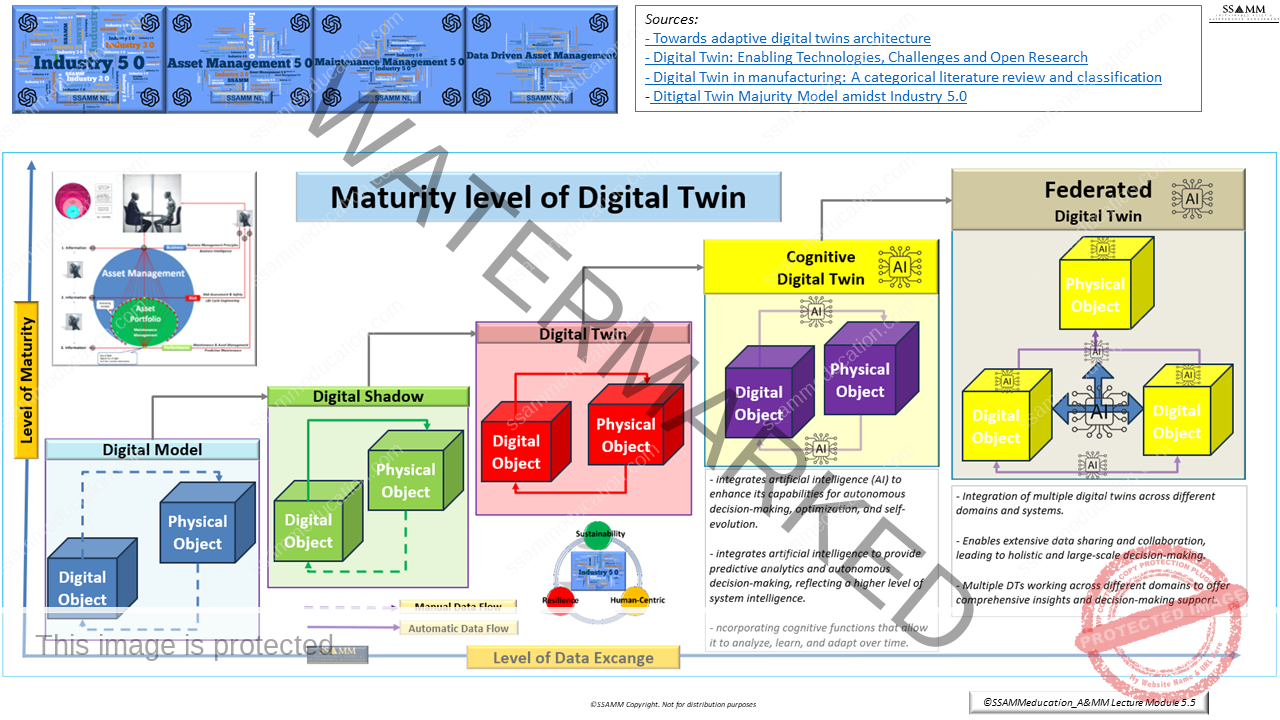

The ability to predict, prepare, and prevent became significantly enhanced, with digital twins and advanced analytics facilitating a much more refined control over assets and operations. Now as we find ourselves on the cusp of Industry 5.0, an era anticipated to harmonize human creativity with machine intelligence, Maintenance Management 5.0 is unfolding. Its ethos doesn’t just lie in leveraging advanced technologies for asset optimization, but emphasizes a human-centric approach. Here, the maintenance narrative extends beyond just machinery efficiency to embody Human-Machine synergy, Adaptive Maintenance, and Resilient Infrastructure. It’s about crafting collaborative environments where human intuition enriches machine precision, building systems that evolve with real-time conditions, and fostering robust infrastructures that ensure operational continuity amidst disruptions. Each stage of Maintenance Management didn’t just mirror its respective industrial era but acted as an enabling force, a catalyst aiding industries to unlock the full potential of the technological innovations at their disposal. And as Jan Stoker delves deeper into Maintenance 5.0 amidst the Industry 5.0 timeframe in the following discourse, the significance of this synchronized evolution stands to be explored further, unveiling how the fusion of human creativity with machine intelligence is about to redefine the vistas of asset and maintenance management.

Countdown SSAMM Academy Module 1

Explore the SSAMM Academy Asset Management and Maintenance Management courses.

Click Here for the Smart information page

Author: Ing. Jan Stoker MSc. MEng. Follow Jan Stoker

1. Alignment of Maintenance Management and the Industry timeframe’s.

The inexorable march of industrial revolutions from Industry 1.0 to the impending Industry 5.0 has been mirrored by the evolution of Maintenance Management paradigms. The alignment of these paradigms with their respective industrial eras is not merely a reactive adaptation, but a crucial factor underpinning the successful maturation and utilization of each era’s technological advancements.

In the era of Industry 1.0, where the muscle of steam and water-powered machines first flexed, Maintenance Management 1.0 was birthed, primarily focusing on reactive maintenance to keep the nascent industrial machinery operational. The basic notion was to fix what broke; a simplistic yet essential response to the dawn of mechanized production.

With the advent of Industry 2.0, electrification and the assembly line brought about mass production, urging the shift to Maintenance Management 2.0. This era saw the advent of preventive maintenance where routine checks and basic maintenance schedules were established to minimize unexpected downtimes, marking a leap towards a more structured and planned approach to maintenance.

As Industry 3.0 emerged, the infusion of digital technology and automation into production systems ushered in Maintenance Management 3.0. Predictive maintenance became the vanguard, leveraging data analytics to foresee and address potential issues before they morphed into significant problems, thereby further minimizing downtime and optimizing operational efficiency.

Industry 4.0 exploded onto the scene with a flourish of cyber-physical systems, IoT, and big data analytics. Here, Maintenance Management 4.0 leveraged these technologies for real-time monitoring, predictive analysis, and proactive maintenance strategies. The creation of digital twins and the utilization of advanced analytics enabled a nuanced understanding and control over assets and operations, marking a significant stride towards autonomous maintenance.

Now, on the cusp of Industry 5.0, the focus is pivoting towards a harmonious blend of human creativity with machine intelligence. This transition is propelling Maintenance Management into its 5.0 iteration, emphasizing a human-centric approach. The narrative extends beyond machinery efficiency to encompass Human-Machine synergy, Adaptive Maintenance, and Resilient Infrastructure, encapsulating a holistic vision of asset optimization.

1.1 Alignment

The alignment of Maintenance Management paradigms with their respective industrial eras is imperative as it enables industries to fully harness and optimize the technological innovations at their disposal. Each iteration of Maintenance Management has acted as a catalyst, driving industries to not only adapt but thrive amidst the technological advancements of their times. As we venture into the era of Industry 5.0, the synchronization of Maintenance Management 5.0 with this new industrial paradigm is poised to unlock unprecedented levels of efficiency, sustainability, and operational excellence, crafting a new narrative for the future of industrial operations.

2. Maintenance Management 1.0

The inception of Industry 1.0, also known as the Industrial Revolution, marked a significant turning point in history around the late 18th and early 19th centuries. This epoch witnessed the transition from hand production methods to machine-centric operations powered predominantly by steam and water. The automation of mechanical manufacturing initiated a journey towards industrial growth and technological advancements. However, this nascent stage of industrialization also gave birth to the rudimentary yet crucial framework of Maintenance Management 1.0, setting the stage for the evolution of maintenance protocols.

Maintenance Management 1.0 can be broadly defined as a reactive or corrective maintenance strategy, where the primary focus was on repairing equipment only after a failure occurred. During this phase, there were no sophisticated maintenance schedules or predictive models in place. The machinery, being novel and less complex compared to what came in subsequent industrial eras, required a straightforward approach to maintenance.

Let’s consider a textile factory operating during the early days of Industry 1.0. With a plethora of steam-powered looms and spinning frames, the production line was a hive of mechanical activity. When one of these machines encountered a breakdown, it necessitated immediate attention to restore functionality. The technicians or mechanics of that era were summoned post-failure, tasked with identifying the root of the problem and implementing the necessary repairs to resume production.

2.1 The impact of Maintenance Management 1.0

The impact on technicians stepping into the Industry 1.0 and Maintenance Management 1.0 scene was manifold:

-

Skill Demands: Technicians were required to have a hands-on, practical understanding of the machinery to troubleshoot and rectify issues efficiently. Their skills were honed through experience and on-the-job learning rather than formal training or through sophisticated diagnostic tools that came in later eras.

-

Reactive Work Environment: The reactionary nature of Maintenance Management 1.0 meant that technicians operated in an environment of urgency, often under pressure to restore functionality swiftly to minimize production downtime.

-

Safety Concerns: The safety protocols during this era were not as stringent or developed as in the later industrial phases. Technicians often worked in perilous conditions, with the risk of injuries being considerably higher.

-

Lack of Predictive Resources: The absence of predictive maintenance tools meant that technicians were always on their toes, ready to tackle unforeseen breakdowns rather than having a structured, planned approach to maintenance that could preemptively address potential issues.

-

Job Security and Demand: The indispensable role of technicians in keeping the machines running translated to job security and a steady demand for skilled technicians. However, the lack of technology also meant that their work was heavily manual and at times tedious.

The juxtaposition of Maintenance Management 1.0 with Industry 1.0 encapsulates a period of technological infancy intertwined with reactive maintenance protocols. While this period laid the foundational stone for more sophisticated maintenance strategies, it also highlighted the importance and evolving role of technicians amidst the industrial tableau. Through the lens of Maintenance Management 1.0, we glimpse the budding synergy between human expertise and mechanical innovation, a synergy that has continually evolved, shaping the narrative of subsequent industrial revolutions and maintenance management paradigms.

3. Maintenance Management 2.0

As the world transitioned into the Industry 2.0 era, the phase popularly known as the Technological Revolution, a notable shift was witnessed from steam power to the dominance of electricity and internal combustion engines, spanning from the late 19th to early 20th centuries. This period heralded a new dawn of increased production capability, greater machine complexity, and a burgeoning sense of industrial efficiency. Amidst this shift, Maintenance Management too evolved, transcending from the reactionary protocols of Maintenance Management 1.0 to a more structured and planned approach known as Maintenance Management 2.0.

Maintenance Management 2.0 was characterized by a preventative maintenance strategy where the emphasis shifted from merely reacting to machine failures to preventing them through routine inspections and maintenance. This proactive approach aimed at reducing unexpected breakdowns, thus improving machine availability and extending asset lifespan.

Let’s illustrate this evolution through an example of a manufacturing facility specializing in automotive parts during the early 20th century. In this facility, electrically-powered assembly lines had become the backbone of operations. Under Maintenance Management 2.0, a maintenance schedule was established, wherein technicians would routinely inspect machinery for signs of wear and tear, lubricate moving parts, and replace components nearing the end of their operational life before they could fail and halt production.

3.1 The impact of Maintenance 2.0

The arrival of Industry 2.0 and Maintenance Management 2.0 encapsulated several impacts on technicians:

-

Increased Predictability: Unlike the reactive environment of Maintenance Management 1.0, technicians in this era were equipped with a scheduled maintenance plan, providing a sense of predictability and organization in their daily tasks.

-

Skill Enhancement: The sophisticated nature of electrical and internal combustion-powered machinery demanded a higher level of technical knowledge. Technicians now needed to understand more complex systems and the underlying principles of preventive maintenance.

-

Safety Improvements: With planned maintenance, there was a reduction in emergency repair scenarios, which in turn contributed to a safer working environment. Predictive measures lessened the chances of abrupt machine failures that could potentially pose risks to technician safety.

-

Efficiency and Productivity: The structured approach of Maintenance Management 2.0 allowed for better planning and allocation of resources, which in turn enhanced operational efficiency and productivity.

-

Documentation and Record-Keeping: The introduction of routine inspections and scheduled maintenance necessitated meticulous record-keeping to track maintenance activities, machine performance, and replacement of parts.

-

Job Satisfaction: The orderly nature of preventative maintenance, along with improved safety standards, likely contributed to enhanced job satisfaction among technicians.

The juxtaposition of Maintenance Management 2.0 with Industry 2.0 mirrors a paradigm shift towards a more organized, safer, and efficient maintenance strategy. The forward momentum from merely reacting to machine failures towards preventing them symbolized a significant leap in the maintenance management narrative. This proactive ethos not only mitigated the adversities of unexpected downtime but laid a robust foundation for the advent of more advanced maintenance management paradigms in the subsequent industrial eras.

4. Maintenance Management 3.0

As the globe pivoted towards the Industry 3.0 era during the latter half of the 20th century, a new chapter was opened in the annals of industrial progression. This epoch, also referred to as the Digital Revolution, was hallmarked by the proliferation of computers and automation in industrial processes. Suddenly, the erstwhile mechanical and electrical machinery were being augmented or replaced by computer-controlled systems. Amid this change, Maintenance Management too underwent a significant transformation, evolving into Maintenance Management 3.0.

Maintenance Management 3.0 ushered in a regime of predictive maintenance, a leap from the preventive maintenance protocols of the previous era. Now, the maintenance strategy hinged on predicting when a machine would fail or require maintenance, leveraging data and analytics. This was made possible by the availability of computers and software that could process vast amounts of data to predict equipment failure before it occurred.

For instance, consider a modern bottling plant during the dawn of Industry 3.0. In this facility, the bottling machines were equipped with sensors and connected to computers capable of monitoring the machines’ performance metrics in real-time. Through analyzing data trends, the system could predict when a component was likely to fail, thus enabling maintenance to be scheduled before a breakdown occurred.

4.1 The Imapct of Maintenance Management 3.0

The evolution to Maintenance Management 3.0 bore several significant impacts on technicians:

-

Data Driven Decisions: The onset of a data-driven approach equipped technicians with actionable insights, enabling them to make more informed decisions. Predictive analysis fostered an environment where maintenance activities were scheduled based on data rather than solely on time intervals.

-

Skill Diversification: The blend of computers and automation in maintenance management necessitated technicians to acquire new skills in data analysis and computer operations, on top of their mechanical and electrical expertise.

-

Increased Efficiency: Predictive maintenance meant fewer unplanned downtimes and better planning, resulting in improved operational efficiency and potentially longer asset life.

-

Enhanced Safety: By predicting and preventing catastrophic failures, the working environment became safer. Technicians were less likely to deal with emergency repairs which inherently pose more safety risks.

-

Resource Optimization: With predictive analytics, resources could be allocated more effectively, reducing waste and promoting better utilization of both human and material resources.

-

Heightened Job Satisfaction: The newfound ability to thwart machine failures before they occurred, coupled with an enhanced skill set, likely contributed to higher levels of job satisfaction among maintenance professionals.

-

Improved Record-Keeping: The digital nature of Industry 3.0 facilitated a more systematic and accessible way of documenting maintenance activities, creating a rich repository of historical data beneficial for future predictive analysis and training.

The alignment of Maintenance Management 3.0 with Industry 3.0 was emblematic of a fundamental shift from a structured, scheduled-based maintenance to a more sophisticated, data-driven predictive maintenance strategy. This transformation not only paved the way for increased operational efficiency but also for the upcoming wave of innovations encapsulated in Industry 4.0 and Maintenance Management 4.0.

5. Maintenance Management 4.0

As the industrial realm transitioned into Industry 4.0, often termed as the fourth industrial revolution, it was the advent of smart factories and the Internet of Things (IoT) that took center stage. In this era, machines started to communicate with each other and with humans in real-time, amassing data at an unprecedented scale. Following suit, Maintenance Management 4.0 emerged, underpinned by the principles of connectedness, big data, and real-time analytics. This epoch saw a shift from mere predictive maintenance to proactive and prescriptive maintenance paradigms.

Maintenance Management 4.0 can be epitomized through an interconnected, data-driven, and analytics-centered approach. For instance, in an advanced automotive manufacturing plant, every robot, conveyor belt, and assembly station is laced with sensors and interconnected through a robust IoT network. Through this network, real-time data concerning the performance, efficiency, and health of each asset is relayed to a centralized system, often cloud-based, where it’s analyzed. The analytics software could predict potential faults, prescribe preventive measures, and autonomously trigger maintenance processes when necessary, minimizing unplanned downtimes and ensuring optimal performance.

5.1 Impact of Maintenance management 4.0

Impact on Technicians:

-

Multifaceted Skill Demands: The influx of smart technologies required technicians to develop digital competencies alongside their traditional mechanical or electrical expertise. Proficiency in software usage, data analytics, and cybersecurity became nearly as crucial as wielding a wrench.

-

Real-Time Insights: Technicians now had access to real-time data and analytics, offering a precise understanding of equipment performance and maintenance requirements. This revolutionized troubleshooting, reducing time spent on identifying issues.

-

Automation of Routine Tasks: Many mundane and routine maintenance tasks became automated, allowing technicians to focus on more complex, value-added activities. It heralded an era where their role transitioned from fixers to strategic enablers.

-

Enhanced Safety Measures: With real-time monitoring and predictive alerts, the working environment became notably safer. Moreover, augmented reality (AR) and virtual reality (VR) started to be used for training and remote assistance, further enhancing safety and efficiency.

-

Advanced Decision-Making: Armed with prescriptive analytics, technicians could make more informed, data-backed decisions, significantly boosting operational efficiency and asset longevity.

-

Collaborative Working Environment: Industry 4.0 fostered a collaborative environment where human expertise and smart technology complemented each other, promoting cross-functional cooperation between maintenance, operations, and IT departments.

-

Continuous Learning and Adaptation: The rapid evolution of technology necessitated a culture of continuous learning and adaptation among technicians to keep pace with emerging tools and methodologies.

Maintenance Management 4.0, riding on the back of Industry 4.0, underscored a monumental shift towards a more integrated, data-centric, and forward-looking approach to asset management and maintenance. As technicians embraced new digital tools and analytics-driven processes, they became pivotal players in driving operational excellence, setting a solid foundation for the human-centric innovations of Industry 5.0 and Maintenance Management 5.0.

6. Maintenance Management 5.0

As the industrial sphere gracefully transitions into the dawn of Industry 5.0, a realm where human ingenuity intersects with technological brilliance emerges. Unlike its predecessor, Industry 5.0 orchestrates a harmonious human-machine collaboration, fostering creativity, resilience, and sustainability. Nestled within this transformation lies Maintenance Management 5.0, an epoch that reimagines asset and maintenance management from a holistic, human-centric lens.

Illustratively, envision a futuristic manufacturing plant where humans and robots work side by side, constantly learning from one another. In Maintenance Management 5.0, smart robots equipped with AI can predict when a machine is likely to fail and suggest preventive measures. However, the human technician, with years of experience, can not only validate these predictions but also employ his intuitive knowledge to enhance the predictive models the robots use, creating a symbiotic relationship of continuous improvement.

6.1 Industry 5.0 further explained

From the rudimentary mechanics of Industry 1.0, the electrification in Industry 2.0, the digital awakening in Industry 3.0, to the smart automation of Industry 4.0, each era has been a precursor to the next, enriching the lexicon of production. As we find ourselves on the cusp of Industry 5.0, as articulated by the European Union report dated 5 January 2021. This transformation is not merely a technological shift, but an ideological one, aiming to synchronize the prowess of human ingenuity with technological advancements. Industry 5.0 focuses on three pivotal axes: human-centricity, resilience, and sustainability, which are expounded below.

6.1.1 Human-Centric

Human-centricity is at the heart of Industry 5.0, transcending the notion of technology as a mere tool to a collaborative partner. Unlike the precedence of Industry 4.0 where automation reigned, Industry 5.0 envisages a workspace where humans and machines co-create, leveraging each other’s strengths. The EU report underscores a philosophy where technological advancements serve to amplify human capabilities rather than replace them. It cherishes human creativity, empathy, and moral judgment as irreplaceable assets in the evolving industrial landscape. This new paradigm facilitates the creation of personalized products and services, delivering value that is intricately tied to human insight and experience.

6.1.1 Resillience

The call for resilience resounds in the fabric of Industry 5.0, more so in a world where uncertainties have become the norm. As per the EU report, the human-machine synergy intrinsic to Industry 5.0 is fundamental to building resilient systems capable of adapting to a gamut of challenges, be it economic, environmental, or social. The agile decision-making process, fortified by the human-technological interface, empowers organizations to anticipate, respond, and adapt to disruptions, ensuring an operational continuity that is crucial in today’s volatile industrial sphere.

6.1.1 Sustainability

Sustainability forms a vital cornerstone of Industry 5.0, addressing the environmental and ethical imperatives facing modern industry. The EU report accentuates the role of Industry 5.0 in fostering a sustainable production and consumption model. By aligning human ingenuity with technological innovation, Industry 5.0 aims at developing eco-efficient production processes, reducing waste, and promoting the circular economy. This era underlines the importance of making conscientious decisions that not only drive economic growth but also safeguard the environment and societal well-being.

The essence of Industry 5.0 as delineated in the EU report is a clarion call for an industrial renaissance where humans and machines harmonize in a symbiotic milieu. It’s a vision of an industrially advanced yet humane society that thrives on collaboration, resilience, and sustainability. Through the lens of Industry 5.0, the future of the industrial sector is not merely technologically advanced but ethically responsible and human-centric.

6.2 The impact of Maintenance Management 5.0

Impact on Technicians:

-

Enhanced Collaboration: In this era, technicians form a part of a collaborative ecosystem where their tacit knowledge complements machine precision, leading to more accurate maintenance predictions and better asset optimization.

-

Augmented Problem-Solving: Equipped with advanced tools like Augmented Reality (AR), technicians can now visualize complex machine problems through a digital lens, enabling faster and more effective problem-solving.

-

Elevated Roles: With routine tasks automated, technicians are elevated to more strategic roles, focusing on improving system designs, enhancing predictive models, and ensuring a culture of continuous improvement.

-

Continuous Skill Evolution: The blended human-machine workspace necessitates continuous skill evolution for technicians, fostering a culture of lifelong learning and adaptation to new technologies.

Click to enlarge: classifications digital twins towards Industry 5.0 (Click here for full article)

6.3 Human-Centric in Maintenance Management 5.0

In the heart of Industry 5.0, the human-centric paradigm redefines how maintenance management functions. Maintenance Management 5.0 enshrines human intuition and expertise as invaluable assets, crucial for refining machine learning models, making informed decisions, and driving innovation in maintenance strategies. This human-centric approach does not just amplify the efficiency and accuracy of maintenance processes, but also fosters a nurturing environment for creativity and innovation.

6.4 Rescilliance as a cornerstone of Maintenance Management 5.0

In the heart of Industry 5.0, the human-centric paradigm redefines how maintenance management functions. Maintenance Management 5.0 enshrines human intuition and expertise as invaluable assets, crucial for refining machine learning models, making informed decisions, and driving innovation in maintenance strategies. This human-centric approach does not just amplify the efficiency and accuracy of maintenance processes, but also fosters a nurturing environment for creativity and innovation.

6.5 Sustainability envisioned through Maintenance Management 5.0

Sustainability is at the forefront of Industry 5.0, and Maintenance Management 5.0 is a vessel through which sustainable practices are implemented and promoted. Through effective asset management, resources are optimized, waste is minimized, and the lifespan of equipment is extended. Furthermore, the collaborative efforts between humans and machines facilitate the creation and implementation of eco-friendly maintenance strategies, driving the industry towards a greener future.

7. Maintainability in the Industry 5.0 timeframe

The emergence of Industry 5.0 and advancements in artificial intelligence (A.I.) have brought significant changes to the concept of maintainability. In order for organizations to remain competitive, they must adapt their maintenance strategies to meet the demands of these new technologies.

One such adaptation is seen in the ISO55000 Asset Management standard, which emphasizes the importance of considering long-term asset performance and sustainability. This means that maintenance management must now consider not only short-term costs but also long-term impacts on asset lifespan and overall efficiency.

In particular, A.I. has a major impact on aging assets or those designed in previous eras without consideration for advanced technologies. With A.I., these assets can now be monitored and analyzed in real-time, allowing for predictive maintenance to identify potential issues before they escalate. This not only extends the lifespan of these assets but also increases their reliability and availability.

On the other hand, A.I. also has a significant impact on maintainability for assets designed in the Industry 5.0 timeframe. With A.I.-enabled technologies integrated into design processes, maintenance requirements can be identified and addressed at the initial stages of development. This leads to improved ease of maintenance, reducing downtime and costs in the long run.

Furthermore, A.I. can also enhance data analysis capabilities, providing valuable insights into asset performance and identifying areas for improvement in terms of maintainability. By leveraging this data, organizations can continuously refine their maintenance strategies and optimize asset performance. This not only contributes to overall efficiency but also aligns with the ISO55000 and ISO13306 standards.

In addition, the IEC 60300-3-10 standard provides guidance for measuring and evaluating maintainability in the Industry 5.0 timeframe. By following this standard, organizations can assess their maintenance processes and make necessary improvements to ensure maximum performance and availability of assets. This not only helps in meeting the requirements of ISO55000 but also ensures compliance with industry regulations.

Overall, maintainability in the Industry 5.0 timeframe is heavily reliant on A.I. and its capabilities to improve asset performance and reduce maintenance efforts. By implementing A.I.-enabled maintenance management strategies, organizations can ensure maximum efficiency, reliability, and availability of assets while aligning with global standards and regulations. It is clear that A.I. has become an integral part of modern day maintenance practices in the Industry 5.0 era, paving the way for more advanced and effective maintenance processes.

So, it is crucial for organizations to embrace A.I. and incorporate it into their asset management strategies to stay ahead in the ever-evolving landscape of Industry 5.0. With A.I., organizations can not only improve their bottom line but also contribute to a more sustainable future by optimizing asset performance and reducing energy consumption. Let us embrace A.I. as a powerful tool for maintainability in the Industry 5.0 timeframe and move towards a more efficient, reliable, and sustainable world together.

7.1 Maintainability related with Resilliance, Human-Centric and Sustainability

Maintainability with the Industry 5.0 ‘Resilience’ perspective is a crucial aspect to ensure the long-term success of any organization. As per ISO13306, resilience is defined as the ability of an asset or system to withstand and recover from disruptive events, minimizing their impact on performance and operations. This aligns perfectly with the concept of maintainability in Industry 5.0, where organizations must focus on ensuring that assets can not only perform as required but also quickly recover from any maintenance-related disruptions.

In order to achieve this, organizations must adopt a holistic approach to asset management, incorporating both A.I.-enabled maintenance strategies and adhering to global standards such as ISO55000. These standards provide a framework for effective asset management practices, including the selection of appropriate maintenance strategies based on risk assessments and life cycle analysis. By following these guidelines, organizations can ensure that their assets remain resilient in the face of any challenges in the Industry 5.0 era.

Moreover, maintaining assets at optimal levels also contributes towards achieving sustainability goals set by various international bodies such as the United Nations Sustainable Development Goals (SDGs). A.I. technology has the potential to optimize asset performance and reduce energy consumption, making it an essential tool for organizations looking to contribute towards a

Maintainability with the Industry 5.0 ‘Human-Centric’ perspective, as defined by IEC60300-3-10, is a key element of this approach. It takes into consideration the human factor in asset maintenance and management, emphasizing the importance of training and competency development for personnel involved in these activities. By providing continuous support and empowering employees with the necessary skills, organizations can ensure that their assets are maintained effectively and efficiently, ultimately contributing to long-term success and sustainability.

Maintainability with the Industry 5.0 ‘Sustainability’ perspective also aligns with the principles of ISO13306, which focuses on minimizing downtime and maximizing asset availability through effective maintenance management strategies. By implementing A.I.-enabled maintenance solutions, organizations can reduce unexpected failures and optimize maintenance schedules, leading to improved asset performance and reduced environmental impact.

8. Maintenance Management 5.0 through the Lens of Resilience-Based Maintenance (RBM)

This chapter is based on the recent article “Towards Maintenance 5.0: Resilience-Based Maintenance in AI-Driven Sustainable and Human-Centric Industrial Systems.” It follows the authors’ PRISMA-guided synthesis and their integrated framing of RBM at the intersection of resilience, sustainability, and human-centric design. all credits to the authors: Lech Bukowski and Sylwia Werbinska-Wojciechowska. Full Artile Click Here

8.1 Why this paper, why now

Maintenance Management 5.0 signals a shift from merely preventing failures to assuring continuity under uncertainty. In a world of volatile demand, stressed supply chains, cyber–physical dependencies, and demanding ESG targets, the ability to absorb shocks, adapt quickly, recover fast, and keep learning becomes the defining capability of the maintenance function. This paper summarises that shift and shows how Resilience-Based Maintenance (RBM) provides the operating core that makes Maintenance 5.0 tangible—strategically, operationally, and technologically.

8.2 What we mean by Maintenance Management 5.0

At its heart, Maintenance Management 5.0 combines three ambitions. These are not parallel initiatives but co-equal design criteria that must be embedded into strategy, processes, technology, and governance. The bullets below state the essence; the paragraphs that follow make them concrete.

-

Human-centricity. People remain in control; technology augments judgment, safety, and learning.

-

Resilience. Systems are managed to absorb, adapt, recover, and learn when disruptions occur.

-

Sustainability. Decisions integrate energy, emissions, circularity, and lifecycle value alongside reliability, risk, and cost.

Human-centricity translates into design choices that respect cognitive and physical limits: explainable recommendations at the point of work; ergonomic procedures and safe access; clear override authority; and competence development that keeps operators, planners, and engineers effective as autonomy rises. The objective is not to replace expertise, but to elevate it with decision support that is transparent and auditable.

Resilience turns prediction into continuity. Beyond estimating Remaining Useful Life (RUL), we plan how the system continues to meet its function when a failure looms or a disturbance strikes. That implies deliberate redundancy (technical and organisational), adaptive scheduling under uncertainty, and pre-validated recovery paths that shorten time-to-recover and prevent backlog spirals.

Sustainability becomes part of the decision function, not an after-the-fact report. Maintenance choices explicitly weigh energy intensity, CO₂ per intervention, and circularity options alongside cost, availability, and risk. This alignment ensures that operational continuity does not come at the expense of environmental performance—or vice versa.

8.3 Resilience-Based Maintenance (RBM): an expanded explanation

Resilience-Based Maintenance (RBM) is a system-level strategy that unifies four capabilities: adaptability (policies and plans adjust to context), redundancy (alternate pathways and safeguards), recovery (rapid restoration of function), and learning (every event improves the next decision). RBM builds on RCM, CBM/PdM, and prescriptive maintenance, but extends them by orchestrating responses at system level—across assets, processes, supply, and people—so that prediction is connected to action, and action is connected to accountability and improvement.

8.3.1 Definition and system vantage point

Resilience-Based Maintenance (RBM) is a system-level maintenance strategy that aims not only to predict and prevent failures, but to sustain required function under uncertainty and to restore performance rapidly after disturbances while learning from each event. Conceptually, RBM draws from resilience engineering and complex systems theory: industrial assets are embedded in socio-technical networks (people, processes, supply chains, digital infrastructure) whose behaviour under stress cannot be managed by component-centric policies alone. RBM therefore reframes maintenance as resilience orchestration across the full system—assets, operations, logistics, and human decision-making—using four mutually reinforcing capabilities: adaptability, redundancy, recovery, and learning.

8.3.2 Core capabilities of RBM

Adaptability denotes the capacity to adjust maintenance policies, plans, and resource allocations in response to shifting conditions (e.g., variable demand, sensor-indicated degradation, supply delays, or safety constraints). In practice this requires decision layers that weigh multiple objectives (availability, safety, cost, energy/emissions, circularity) and can switch policies when context changes. Techniques range from rules with explicit thresholds to optimisation and reinforcement learning policies validated in digital twins. Importantly, adaptability is not purely algorithmic: it depends on organisational readiness (competences, escalation routes, and governance) to enact a different plan safely and on time.

Redundancy provides alternative pathways to preserve function during partial failure or delayed maintenance. RBM treats redundancy broadly. It includes technical redundancy (active/passive/cold-standby components or parallel flows), logistical redundancy (critical spares, alternative suppliers, multi-skilled crews), and informational redundancy (diverse sensors or models to avoid single-point diagnostic bias). Rather than maximising redundancy indiscriminately, RBM places it where marginal resilience gain per cost and footprint is highest, informed by criticality analysis and scenario stress-testing in digital twins.

Recovery focuses on time-to-recover and the depth of performance loss during an event—the “resilience triangle.” RBM plans recovery pathways in advance: safe fallback modes, controlled slow-downs, bypasses, rapid change-out procedures, and pre-authorised work packages. Scheduling and dispatching rules are designed to clear backlogs without creating new bottlenecks or safety risks. In contrast to classical availability metrics alone, RBM makes recovery dynamics visible and improvable, e.g., by tracking backlog clearance time, spare-latency, crew mobilisation time, and post-event stabilisation time.

Learning closes the loop. Every disturbance and intervention generates data about precursors, decision quality, and unintended effects. RBM formalises this into policy updates (set-points, decision thresholds, standard work), model updates (diagnostics/prognostics retraining with uncertainty recalibration), and design feedback (maintainability improvements). Learning is governed: rationale, overrides, and outcomes are documented to support assurance, audits, and safe roll-out of changes.

8.3.3 How RBM extends RCM, PdM, and RxM

RBM extends familiar strategies—RCM, CBM/PdM, and prescriptive maintenance (RxM)—but is not reducible to any of them:

-

Relative to RCM, RBM retains structured failure logic yet goes beyond static intervals by embedding context-aware adaptation and system-level response planning.

-

Relative to PdM/CBM, RBM connects prediction to continuity: it asks not only when something will fail but how the wider system will keep delivering if failure risk is rising or if intervention must be delayed.

-

Relative to RxM, RBM uses prescriptive analytics to select and schedule actions, but adds explicit resilience objectives (e.g., minimise continuity loss), redundancy design, and human-in-the-loop (HITL) governance to keep responsibility and explainability clear.

A distinctive feature of RBM in the Maintenance 5.0 context is the integration of sustainability into decision-making. Energy-Based Maintenance (EBM) exemplifies this: deviations in energy profiles are treated as first-class health indicators and as cost/footprint drivers. Interventions are therefore assessed on joint impact—continuity, cost, energy, and CO₂—rather than uptime alone. This avoids local optima (e.g., quick fixes that raise energy intensity or scrap rates) and aligns maintenance with lifecycle value and environmental performance.

Operationalising RBM requires an information architecture that supports both timeliness and traceability. At minimum, this includes: (i) reliable time-series sensing for condition and energy, (ii) event and maintenance logs with consistent taxonomies, (iii) context streams (loading, environment, supply), and (iv) data lineage and model registries for assurance. Diagnostics and prognostics should include uncertainty quantification to prevent overconfident recommendations, while decision layers expose explanations at the point of work so technicians and planners understand drivers and constraints. Human oversight is not an afterthought: RBM specifies who can accept recommendations, when overrides are mandatory, and how rationale is captured for later review.

Because resilience is multidimensional, measurement in RBM spans several families of indicators. Classical reliability/availability metrics (MTBF, MTTR, OEE, availability) remain essential but are complemented by recovery dynamics (backlog recovery time; time from event onset to stabilised operation; spare-part and crew response times), adaptivity indicators (policy switch latency; schedule reactivity; opportunity capture rate), learning indicators (post-incident change lead time; reduction in false alarms; improvement in RUL error), sustainability indicators (energy intensity per service unit; CO₂ per intervention; circularity rates), and human-centric indicators (ergonomic risk, explainability/override statistics, competence outcomes). Together they provide a dashboard that prevents one-sided optimisation and supports cross-site benchmarking.

RBM also has a design dimension: it treats maintainability as recoverability-by-design. Access, modularity, standardised interfaces, and diagnostic points are specified not only to reduce planned task time, but to compress unplanned recovery, reduce error potential, and enable safer, lower-energy interventions. Field learning feeds back into design rules so that recurrent pain points are engineered out and spare strategies are rationalised for both continuity and circularity.

From a governance perspective, RBM aligns well with contemporary asset-management and maintenance process frameworks. Risk-based planning, performance evaluation, and continual improvement provide the managerial backbone; process views (data/diagnostics → optimisation → execution → improvement → management/assurance) give RBM a natural landing zone without reorganising the enterprise. As automation rises, trustworthy AI practices—model governance, explainability, bias checks, and documented HITL controls—become essential to keep accountability clear and to meet safety and compliance expectations.

Finally, RBM is pragmatic to adopt. Many organisations already have PdM pilots and prescriptive work selection in place; RBM connects these point solutions into a closed, auditable loop with resilience and sustainability as first-class outcomes. Typical starting moves include (a) adding energy telemetry to selected lines (EBM), (b) defining a small set of recovery metrics and dashboards, (c) building a digital-twin “resilience sandbox” to stress-test policies before deployment, and (d) instituting lightweight but firm HITL governance. The effect is cumulative: as recovery speeds up and decisions become explainable and repeatable, confidence grows to extend RBM across assets, sites, and supply interfaces—bringing Maintenance 5.0 from concept to daily practice.

8.4 Why RBM is the operating core of 5.0

RBM turns sophisticated analytics into assured outcomes. The logic is straightforward: prediction without recovery planning is fragile; action without human oversight is risky; improvement without measurement is arbitrary. RBM addresses all three.

-

From prediction to continuity. Predictive analytics estimate when components may fail; RBM ensures the system keeps functioning while failures are anticipated, buffered, or rapidly recovered. This requires pre-defined policies for throttling, re-routing, or temporary mode switches and the data discipline to trigger them in time.

-

From point solutions to portfolios. RBM links work orders to portfolio-level trade-offs across value, risk, cost, energy, and emissions. Executives see the same logic that planners and engineers use, enabling consistent prioritisation across sites and lines.

-

From black boxes to accountable AI. Digital Twins and optimisation engines are embedded in explainable, auditable decision flows with clear human-in-the-loop control, so responsibilities remain crisp and learning is captured for assurance.

Together these shifts elevate maintenance from a reactive service to a strategic capability. The operating model that enables this is the RBM loop described next.

8.5 The RBM loop we use in practice

We implement RBM as a closed loop, simple to communicate and rigorous to execute. Each step has its own deliverables and governance; skipping one weakens the others.

-

Sense the state of assets, energy use, and operating context (load, weather, supply constraints). The emphasis is on reliable telemetry, event logs, and context signals that allow us to see degradation and opportunity windows early.

-

Interpret with diagnostics, health indices, and uncertainty-aware prognostics (e.g., RUL). Here, physics-informed features and robust data lineage prevent spurious correlations; uncertainty bounds avoid overconfidence.

-

Decide using multi-objective logic (availability, safety, cost, energy/CO₂, circularity), validated in Digital Twins. Recommendations must be explainable, with guardrails for high-risk actions and explicit hand-offs to human decision-makers.

-

Act by adjusting plans and resources (spares, skills, windows), activating redundancy, or executing targeted interventions. Execution includes safe work controls and rapid feedback to scheduling.

-

Learn by comparing expected vs. realised outcomes, updating policies and standard work, and feeding maintainability improvements back into design. Learning is not incidental; it is scheduled and documented.

Around this loop sit familiar process disciplines (data/diagnostics, optimisation, execution, improvement, governance) so the model can be embedded in existing organisations without disruption.

8.6 Where sustainability enters the loop (Energy-Based Maintenance)

In a 5.0 setting, sustainability is not an add-on but part of the decision function. A practical entry point is Energy-Based Maintenance (EBM), in which energy profiles act as first-class signals of degradation and efficiency loss. When RBM treats these signals alongside reliability and cost, interventions achieve continuity and footprint reduction. The following metric families make this integration workable; each bullet is followed by a short explanation that shows how it is used in practice.

-

Continuity metrics. Availability, MTBF/MTTR, backlog recovery time, and the “resilience triangle” (performance loss × time) make recovery visible and improvable.

Explanation. Availability and MTBF/MTTR capture steady-state reliability, but backlog recovery time shows how quickly operations normalise after a disruption. The resilience triangle quantifies the area under the performance curve during a disturbance, translating “pain felt” into a number that planners can reduce through redundancy and smarter rescheduling. -

Sustainability metrics. Energy intensity per service unit, CO₂ per intervention, and circularity (reuse/remanufacture rates) align maintenance with environmental objectives.

Explanation. Energy intensity connects operational settings (e.g., speed, temperature, lubrication) to both degradation and cost. CO₂ per intervention brings logistics, spare-part choices, and rework into view. Circularity rates ensure that repair/replacement decisions reflect reuse and remanufacture options rather than defaulting to new parts. -

Human-centric metrics. Ergonomic risk measures, explainability and override statistics, and competence development outcomes ensure that technology strengthens, rather than replaces, professional judgment.

Explanation. Ergonomic risk highlights tasks where recovery speed today may trade off against health tomorrow. Explainability/override statistics show whether recommendations are trusted and when humans step in—vital for improving models and interfaces. Competence outcomes track whether teams can safely operate at higher autonomy levels.

These indicators do not compete; they complement one another. Continuity without sustainability is shortsighted; sustainability without continuity is impractical. RBM balances both in one coherent scoreboard that managers, engineers, and operators can read together.

8.7 What different roles gain from RBM

Different stakeholders experience RBM through different benefits. Making those benefits explicit aligns incentives and budgets.

-

Executives & Asset Owners. Transparent trade-offs among risk, continuity, cost, and footprint; portfolio options stress-tested in twins; explainable, auditable recommendations that withstand scrutiny.

What this means. With RBM, capital and OPEX decisions are no longer based on isolated KPIs or gut feeling. Scenario-tested options expose hidden risks (e.g., supplier fragility, energy volatility) and quantify the value of redundancy or design changes before money is committed. -

Maintenance Managers & Planners. Stable planning under volatility: faster rescheduling, shorter time-to-recover, smarter use of opportunity windows; repeatable post-incident learning that improves standard work.

What this means. Planners gain policy libraries for typical disruptions (equipment, logistics, labour). When a disturbance hits, the system proposes a vetted plan that respects safety, skills, and spares—reducing firefighting and improving schedule adherence. -

Engineers & Analysts. End-to-end PHM pipelines, uncertainty-aware RUL, and policy libraries validated in Digital Twins; robust data lineage and model governance that keep algorithms dependable.

What this means. Engineering effort shifts from ad-hoc models to maintained pipelines where diagnostics, prognostics, and prescriptive logic evolve with the plant. Twin-validated policies reduce the gap between “model says” and “shop-floor can do.” -

Design & Reliability Teams (Maintainability). Recoverability becomes a design target: accessibility, modularity, safe work envelopes, and diagnostic access that cut MTTR and error potential.

What this means. Field feedback flows back to design rules: frequent failure locations get better access; modules become swappable; and standardised connectors reduce rework. The result is faster, safer, and cleaner interventions.

Seen together, these gains create a reinforcing loop: better design simplifies operations; better operations generate cleaner data; cleaner data improves models; improved models inform better design. RBM is the mechanism that keeps this loop tight and productive.

8.8 Governance and human-in-the-loop

Maintenance 5.0 assumes a simple principle: technology assists; people decide. In our RBM deployments, recommendations are explainable at the point of work, and operators have explicit override authority. Safety and functional-safety practices remain non-negotiable guardrails as autonomy rises. Governance binds the loop together: who may accept recommendations, when overrides are mandatory, how rationale is recorded, and how lessons learned change policy. This is how human-centricity becomes a daily reality—not a slogan, but a documented control model with clear accountability.

8.9 How the conference paper advances the discussion

The paper contributes a concise definition, a reproducible method, a balanced measurement approach, and a pragmatic adoption path. The bullets outline the contribution; the accompanying text clarifies how each item is used.

-

Definition. Maintenance 5.0 as a human-centric, resilient, and sustainable practice operationalised by RBM.

Clarification. Rather than rebranding existing practices, the definition binds human oversight, resilience capabilities, and sustainability objectives into one operating model so that all functions pull in the same direction. -

Method. A reproducible Sense–Interpret–Decide–Act–Learn loop with aligned governance and assurance.

Clarification. The loop avoids tool-chasing by specifying what must happen and how decisions are governed, regardless of vendor stack. This makes pilots comparable and scale-up manageable. -

Measurement. A balanced dashboard that treats resilience and sustainability as first-class metrics.

Clarification. By combining continuity, sustainability, and human-centric indicators, the dashboard prevents local optimisation (e.g., uptime at the cost of health or emissions) and enables cross-site benchmarking. -

Adoption. A pragmatic path to start with energy signals, pilot in twins, and scale with process discipline.

Clarification. EBM offers quick wins and clean feedback loops; Digital Twins derisk policy changes; embedding in existing processes (planning, assurance, improvement) sustains momentum after the pilot glow fades.

8.10 Closing thought

Maintenance 5.0 is not a new label for old practices. With RBM, organisations move from predict and fix to absorb, adapt, recover, and learn. The dividend is assured continuity, safer work, and a measurably lower footprint—with humans firmly in control and technology as an accountable amplifier.

9. Reference Articles

9.1 Industry 5.0 Related

- Maturity assessment for Industry 5.0: A review of existing maturity models

- Industry 5.0: Past, Present and Near Future

- IR5.0 Human-Centric underpinned with 2022 Industrial Maintenance study

- Human in the loop: Industry 4.0 vs. Industry 5.0: Co-existence, Transition, or a Hybrid

- Industry 5.0 further explained

- Industry 5.0 and Society 5.0: Comparison, complementation and co-evolution

- Outlook on human-centric manufacturing towards Industry 5.0

- Maintenance 5.0: Towards a Worker-in-the-Loop Framework for Resilient Smart Manufacturing

- Industry 5.0: Prospect and retrospect

- Industry 5.0 definitions

- Be informed…. we are already in the Industry 5.0 timeframe

9.2 IR4.0 & IR4.0 Readiness

- An Industry 4.0 readiness Assessment tool

- Intelligent warehouse in Industry 4.0

- Maintenance Performance in the Age of Industry 4.0

- Simulating dynamic RUL based CBM scheduling

- Maintenance Analytics – The New Know in Maintenance

- Rethinking Maintenance Terminology for an Industry 4.0 Future

- Maintenance optimization in industry 4.0; Strategies, Information and the Reversed Data Pyramid

- An RUL-informed approach for Life Extension of high-value assets: Overview of LE practice

- Lean Maintenance 4.0: implementation for aviation industry

- Developing prescriptive maintenance strategies in the aviation industry

- Development of flexible Predictive Maintenance systems in the context of industry 4.0: the implementation framework

9.3 Digital Twin Related

- Reflection: Disruptive Innovation Asset & Maintenance Management

- Collecting Real-Time Data for Predictive Maintenance

- Lean Maintenance 4.0: implementation for aviation industry

- A digital twin-based decision analysis framework for operation and maintenance of tunnels

- Digital building twins and blockchain for performance-based (smart) contracts

- IoT for predictive assets monitoring and maintenance: An implementation strategy

- About auditing in the field of Asset Management

- A Digital Twin Design for Maintenance Optimization

- The difference between Machine Learning(ML) and Deep Learning (DP)

- Digital Twin Definitions: a time perspective

- Definition Digital Twin

- Approach for a Holistic Predictive Maintenance Strategy by Incorporating a Digital Twin

- Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning

- Advances of Digital Twins for Predictive Maintenance

- The 250 classifications of Digital Twin technology

9.4 Maintenance Management

- Decision-based framework for Predictive Maintenance Technique selection in Industry 4.0

- Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning

- Recent advances and trends of predictive maintenance from data driven machine prognostics perspective

- Data-driven decision-making for equipment maintenance: Data-driven RCM

- Toward cognitive predictive maintenance: A survey of graph-based approaches

- A deep learning predictive model for selective maintenance optimization

- Inspection schedule for prognostics with uncertainty management

- Development of Digital Twin for Intelligent Maintenance of Civil Infrastructure

- Risk Based Inspection Framework part of evolutions in Maintenance Management; Framework and Process

- KSPMI: A Knowledge-based System for Predictive Maintenance in Industry 4.0

- Sharping the mind: Find The Sweet spot

- The Bathtub Curve Fallacy

- The framework for data-driven maintenance planning and problem-solving in maintenance communities

- The Maintenance Body of Knowledge

- Decision Framework for Predictive Maintenance Method Selection

- Maintenance Engineering defined

- The Maintenance 5.0 Framework

- The Maintenance 5.0 Cycle

9.5 Interpretation Article’s

- Line of Sight: Asset Management in the aligned timeframe

- Interpretation Figure 1 ISO55000

- The elephant in the room

- Asset & Maintenance Management amidst the Industry 5.0 timeframe

- Revised A&MM The Big Picture

- Article IR5.0 Human-Centric

- Explaining Predictive Maintenance using the KISS-Principle

- Asset Management 5.0: Balancing Risk, Performance and Value with IR5.0

- Food for Thoughts: ChatGPT in the field of Asset & Maintenance Management.

9.6 Additional Pages To Consult

- Sustainable Asset Management

- The Maintenance Engineer

- The Maintenance Manager

- The Asset Manager

- Industry 5.0

- Circular Asset Management

Tags: Newsletter 1