Relation to the book “The Maintenance Framework”

This digital article is part of the broader concepts and structure presented in the book The Maintenance Framework by Jan Stoker.

Primary reference

Title:The Maintenance Framework (Click Here)

Author: Jan Stoker

Publisher: SSAMM (Click Here)

ISBN/EAN:: 978-90-8339-896-9

The present article “Qualification of Maintenance Personnel” should be regarded as an online extension and elaboration of the corresponding section in The maintenance Framework. The book remains the primary citable reference for the underlying framework and definitions.

© 2024 Jan Stoker / SSAMM. All rights reserved.

This web content is provided exclusively for registered SSAMM Academy clients under a personal, non-transferable licence. Unauthorised sharing of logins, screenshots, files or copies (in whole or in part) is not permitted.

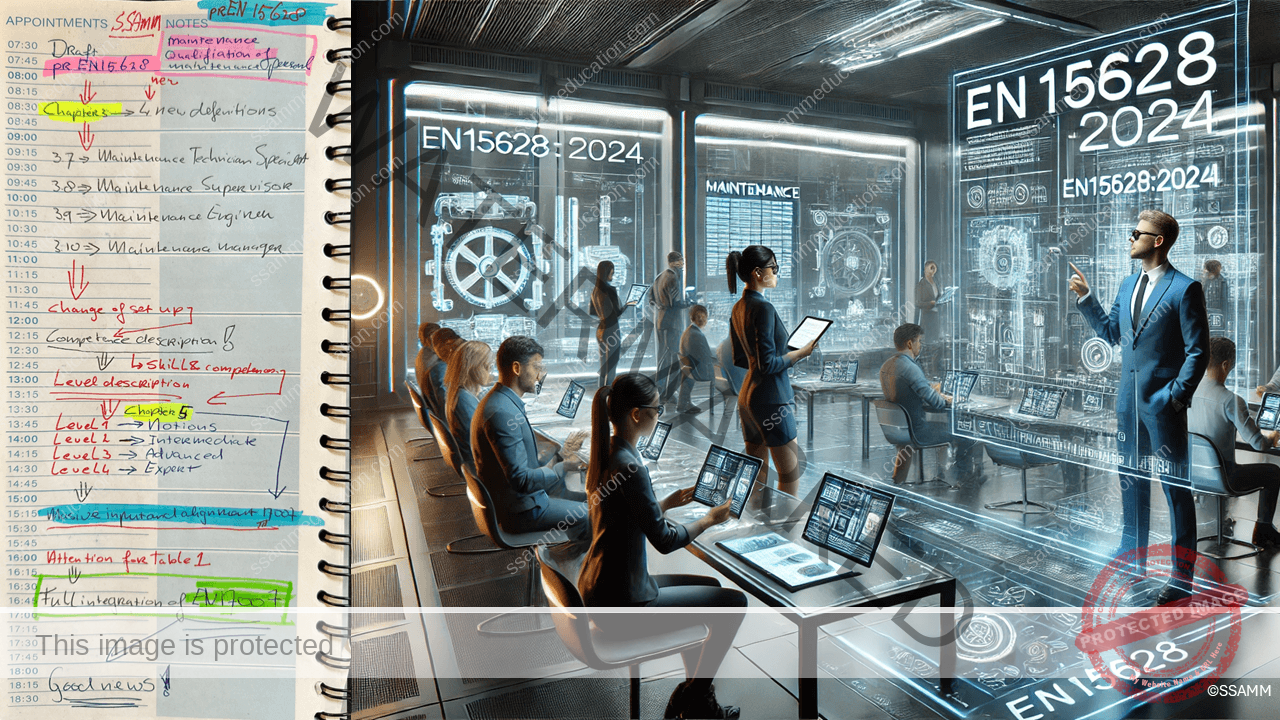

Building upon its predecessor (EN15628:2014), EN15628:2025 aligns closely with complementary standards such as EN17007, which outlines the maintenance process, and the forthcoming ISO550XX:2024, focusing on asset management system requirements. Together, these standards offer a comprehensive framework for organizations aiming to achieve operational excellence through structured maintenance and asset management processes.Central to EN15628:2025 is the detailed delineation of four essential maintenance roles, each tailored to the requirements of Industry 5.0 and Asset & Maintenance Management 5.0.

This article explores these four roles in depth, focusing on the required knowledge, competencies, and skills for effective performance. Additionally, it examines how EN15628:2024 integrates with EN17007 and ISO550XX:2024, emphasizing their collective role in advancing future-proof maintenance and asset management practices.

- Fisrst draft 12 August 2024

- Updated 17 August 2025

- Published 9 September 2025

- Published SSAMM Social Media platforms October 2025

Maintenance Fundamentals SAMM, First Edition Keynote Āpōpō Congres 2026 Follow Sustainable Asset Management for latest updates

Countdown SSAMM Academy Module 1

Explore the SSAMM Academy Asset Management and Maintenance Management courses.

Click Here for the Smart information page

Author: Ing. Jan Stoker MSc. MEng. AMCP. CFAM. Follow Jan Stoker

Introduction

The EN15628:2025 represents a significant evolution in the European standard for the qualification of Maintenance personnel, building upon the foundations of the earlier EN15628:2014. This revision introduces key updates aimed at improving the alignment of Maintenance roles, competencies, and knowledge with contemporary industrial needs and frameworks, providing organizations with a robust framework to enhance Maintenance operations.

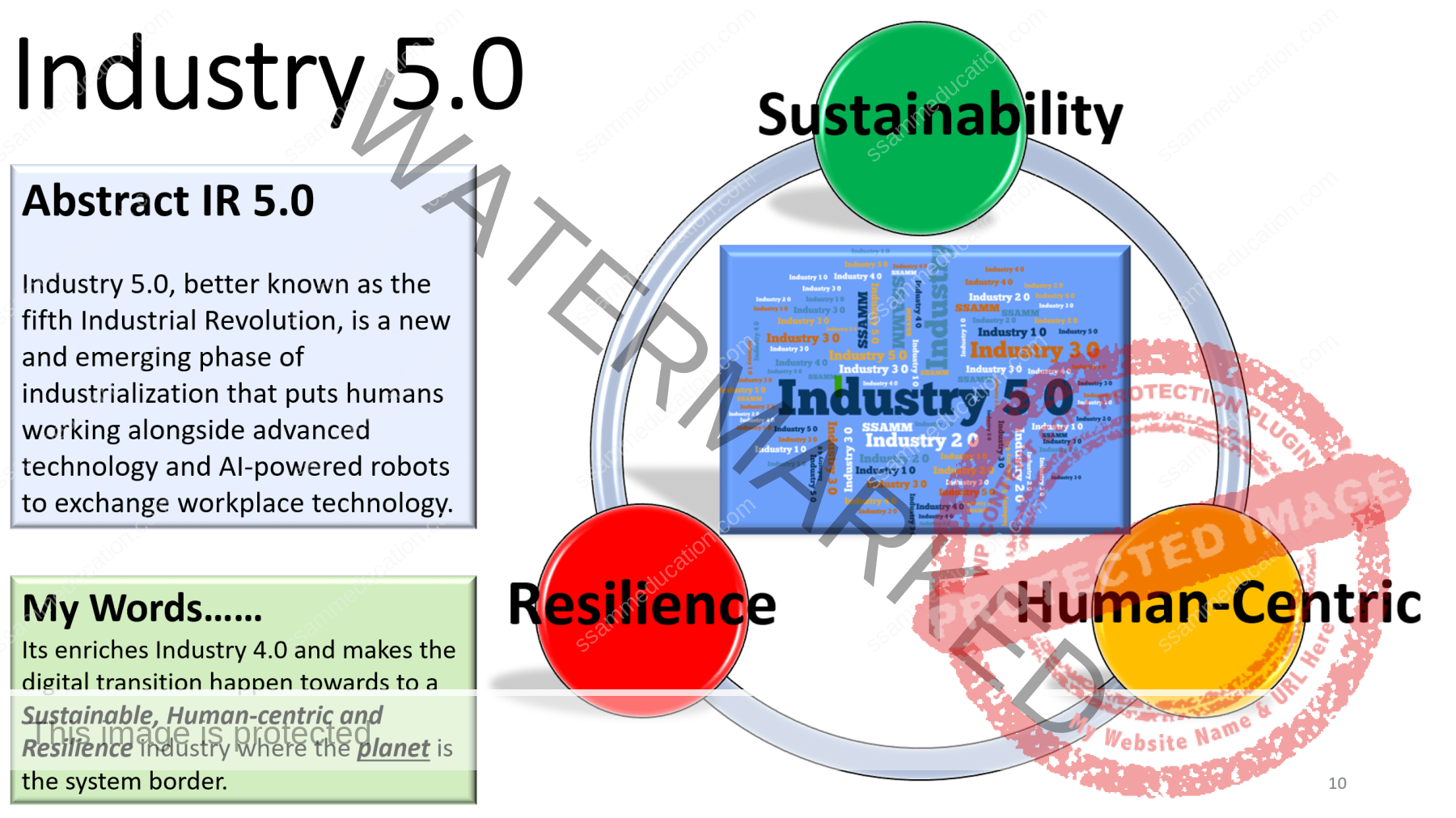

In the context of Industry 5.0, this standard plays a critical role in addressing three central themes: resilience, sustainability, and human-centricity. These principles are not only essential to modern industrial operations but also directly influence how Maintenance teams are structured, trained, and equipped to respond to rapid technological and demographic changes.

Resilience to Technological and Demographic Changes

Demographic shifts, including the aging workforce and challenges in attracting younger professionals to Maintenance roles, further underscore the importance of this standard. The EN15628:2025 addresses this by emphasizing lifelong learning and aligning qualifications with the European Qualifications Framework (EQF). This approach facilitates career development pathways that are attractive to new talent while supporting the upskilling of existing personnel to bridge generational gaps in expertise.

Sustainability in Maintenance Practices

The integration of sustainability into Maintenance activities is a cornerstone of Industry 5.0 and Asset & Maintenance Management 5.0. The EN15628:2025 emphasizes the role of Maintenance in prolonging the lifecycle of assets, reducing waste, and ensuring compliance with environmental regulations. By defining competencies such as managing maintenance during design and modifications, the standard encourages sustainable design principles, including maintainability and resource efficiency.

Furthermore, the knowledge and skills outlined in the standard enable Maintenance personnel to implement energy-efficient practices, minimize environmental impact, and align with broader organizational sustainability goals. This proactive approach positions Maintenance not only as a reactive function but as a strategic contributor to sustainable industrial operations.

Human-Centricity and the Role of Maintenance in Industry 5.0

At its core, Industry 5.0 emphasizes human-centricity, ensuring that technology enhances rather than replaces human expertise. The EN15628:2025 supports this principle by clearly defining roles such as Maintenance Technician, Supervisor, Engineer, and Manager, each of which integrates human judgment, creativity, and leadership with advanced technological tools.

For example, while AI and predictive analytics can automate fault detection and forecasting, human oversight is essential for interpreting data, prioritizing interventions, and making strategic decisions. The standard’s focus on equipping personnel with both technical knowledge and soft skills ensures that Maintenance remains a human-driven, value-adding process.

Enabling Asset & Maintenance Management 5.0

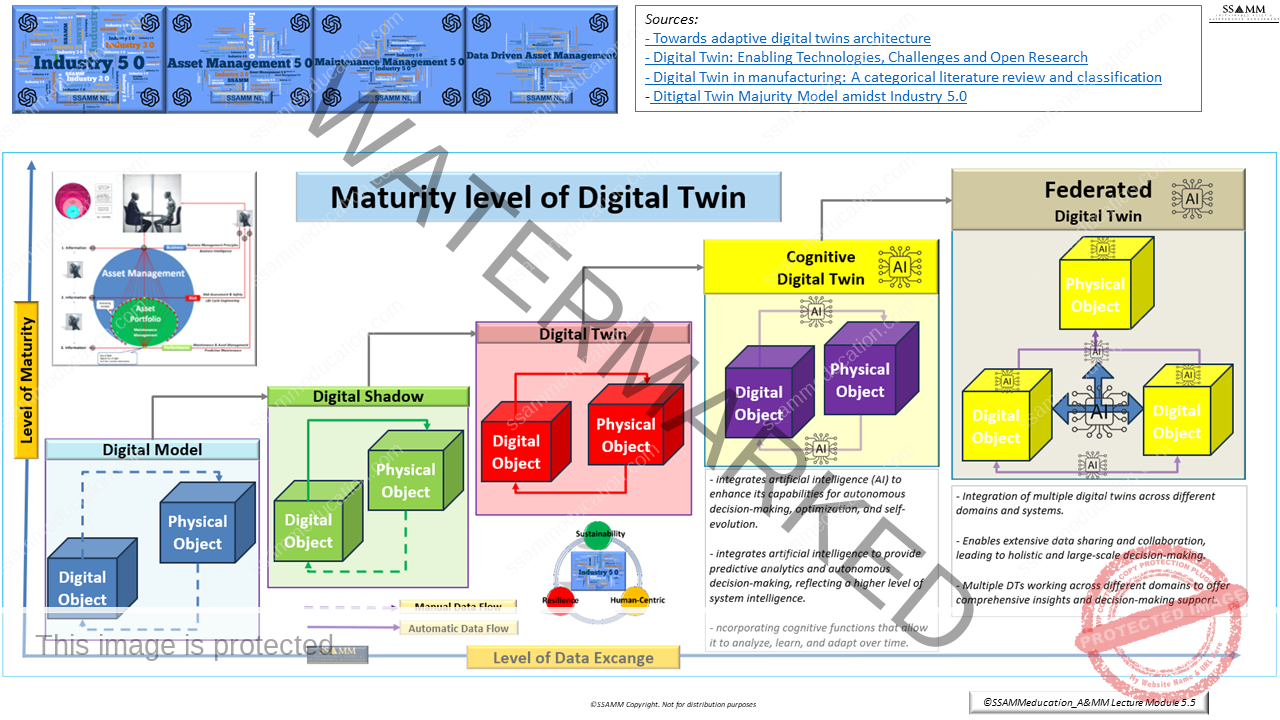

By utilizing digital twins, organizations can monitor asset performance, predict maintenance needs, and optimize decision-making processes based on highly accurate, data-driven insights.

The EN15628:2025 defines clear competences and skills that ensure Maintenance teams are equipped to leverage digital twin technology effectively. These include the ability to manage data, analyze trends, and integrate predictive maintenance methodologies. By embedding these competences within the standard, EN15628:2025 provides a robust framework for organizations to enhance their operational resilience and asset reliability while reducing downtime and costs.

In an era of rapid industrial change, the EN15628:2025 is a vital resource for organizations striving to remain resilient, sustainable, and human-focused. Through the integration of digital twins, Maintenance teams can adapt to technological advancements, optimize resource utilization, and contribute meaningfully to the strategic goals of Industry 5.0. This makes the standard not just relevant but essential for navigating the complexities of modern Maintenance practices and ensuring long-term operational excellence.

1. EN-15628:2025 Advancements in Maintenance Personnel Qualifications

The EN15628:2025 represents a significant evolution in the European standard for the qualification of Maintenance personnel, building upon the foundations of the earlier EN15628:2014. This revision introduces key updates aimed at improving the alignment of Maintenance roles, competencies, and knowledge with contemporary industrial needs and frameworks, providing organizations with a robust framework to enhance Maintenance operations.

1.1 Alignment with EN17007: A Cohesive Framework for Maintenance Processes

One of the central updates in EN15628:2025 is the structural alignment with EN17007, which describes the Maintenance process. This ensures a consistent approach to defining Maintenance activities across management, realization, and support processes. By aligning roles and responsibilities with these process categories, the standard fosters a more integrated and effective implementation of Maintenance practices, bridging gaps between theoretical principles and operational needs.

1.2 Knowledge Requirements and the European Qualifications Framework (EQF)

A major enhancement in EN15628:2025 is the explicit specification of knowledge requirements tailored to the types of Maintenance actions defined in EN17007. This targeted approach ensures that competencies are directly linked to specific tasks, improving the overall effectiveness and precision of Maintenance activities.

The integration of the European Qualifications Framework (EQF) further strengthens the standard by facilitating the recognition and portability of Maintenance qualifications across Europe. This alignment promotes lifelong learning and offers clear pathways for career development, enabling Maintenance personnel to progress from foundational skills to expert levels.

1.3 New Definitions of Maintenance Roles

The EN15628:2025 introduces clear and structured definitions for four key Maintenance roles:

-

Maintenance Technician/Specialist: Responsible for maintaining the physical condition and availability of equipment, performing preventive and corrective Maintenance tasks in line with best practices and legal requirements.

-

Maintenance Supervisor: Oversees and coordinates Maintenance activities conducted by technicians and subcontractors, ensuring effective collaboration among stakeholders.

-

Maintenance Engineer: Applies engineering principles to design for maintainability, resolve technical issues, and enhance asset reliability and performance.

-

Maintenance Manager: Develops Maintenance strategies, policies, and oversees their implementation to achieve organizational objectives while ensuring sustainability and cost-effectiveness.

These role definitions provide clarity on responsibilities and expectations, enabling organizations to structure their Maintenance teams effectively.

1.4 A New Chapter on Skills and Knowledge

A significant addition in this revision is the detailed categorization of skills, knowledge, and competencies within a new chapter. Competencies are outlined in alignment with Maintenance processes, categorized into management, realization, and support functions. Expected expertise levels are classified from basic to expert:

- Level 1: Notions

Possesses basic knowledge and is effective in common and simple situations. Requires supervision or monitoring by a more experienced and competent professional. - Level 2: Intermediate

Demonstrates general and theoretical knowledge, capable of handling common and simple situations without supervision. Lacks solid experience but can act autonomously in standard tasks. - Level 3: Advanced

Holds in-depth theoretical and practical knowledge in the field, along with solid experience. Can independently apply expertise to both common and complex situations. - Level 4: Expert

Recognized as an expert in the field, capable of managing complex and uncommon situations. Considered a specialist who can teach, guide, and transfer knowledge to others.

This structured approach enables organizations to design training and development programs that meet specific operational needs, ensuring personnel at every level are equipped with the required competencies.

1.5 A Comprehensive Framework for Modern Maintenance Practices

The EN15628:2025 is a critical resource for organizations striving for excellence in Maintenance operations. By aligning with EN17007, incorporating the EQF, and providing detailed guidance on roles and skills, the standard offers a practical framework to address the complexities of modern Maintenance practices. This revision not only supports the technical competence of Maintenance teams but also fosters sustainable, effective, and efficient Maintenance management across industries.

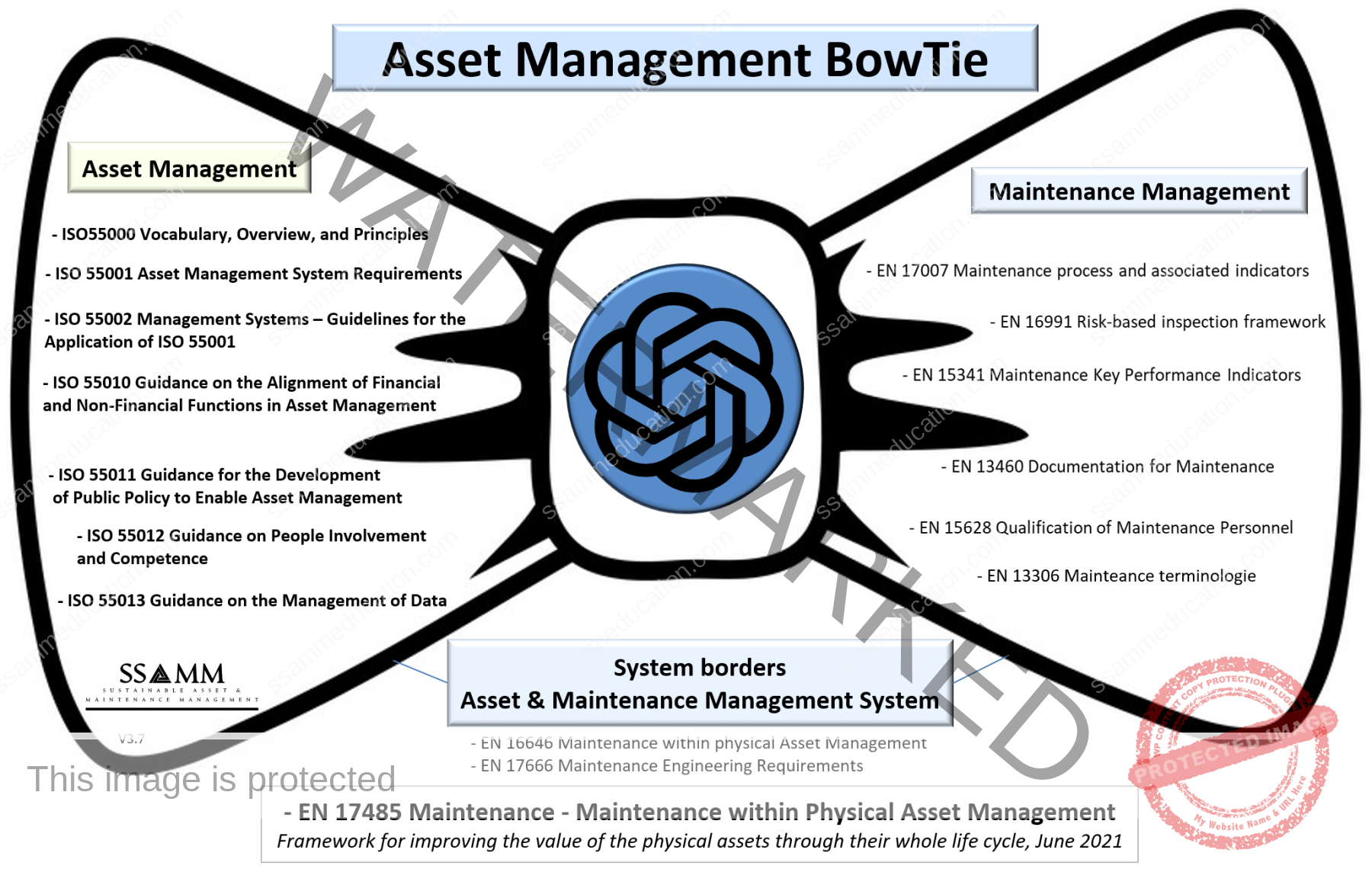

1.6 Normative and Practical Relations with Other Standards

The Asset Management BowTie (Click Here) highlights the critical interrelationships and, in some cases, the normative dependencies between EN15628:2025 and key standards such as ISO550XX:2024, EN16646, EN17666, EN17485, and EN13306. These standards collectively provide a comprehensive approach to managing physical assets and maintaining operational excellence.

- ISO550XX:2024 sets the overarching principles and requirements for asset management systems, emphasizing the integration of Maintenance as a core component of value creation and risk mitigation. The EN15628:2025 supports this by defining the qualifications and competences of Maintenance personnel essential to implementing ISO550XX-compliant strategies effectively.

- EN16646, which addresses the integration of Maintenance within Asset Management, further reinforces the alignment of EN15628:2025 with asset-centric decision-making. This ensures that Maintenance practices are not isolated but contribute directly to achieving broader organizational objectives.

- EN17666, focusing on Maintenance Engineering, provides the technical and methodological foundation for advanced Maintenance practices. The EN15628:2025 complements EN17666 by specifying the required knowledge and skills for engineering roles, ensuring personnel can apply these methodologies effectively.

- EN17485 establishes Maintenance Key Performance Indicators (KPIs) for evaluating effectiveness and efficiency. The competences and skills outlined in EN15628:2025 ensure that Maintenance teams can collect, interpret, and act on KPI data to drive continuous improvement.

- EN13306, which provides the terminology and definitions for Maintenance, serves as the reference point for the consistent language and concepts embedded within EN15628:2025.

These interdependencies ensure that EN15628:2025 is not only a standalone standard for Maintenance personnel qualification but also a critical enabler for achieving compliance and alignment with broader Asset and Maintenance Management frameworks.

For a more detailed exploration of how EN15628:2025 integrates with these standards and supports Asset & Maintenance Management 5.0, readers can refer to SAMM, First Edition (Click here), available on this website. This resource offers a deep dive into the methodologies, practical applications, and strategic insights that align Maintenance practices with organizational goals in the era of Industry 5.0.

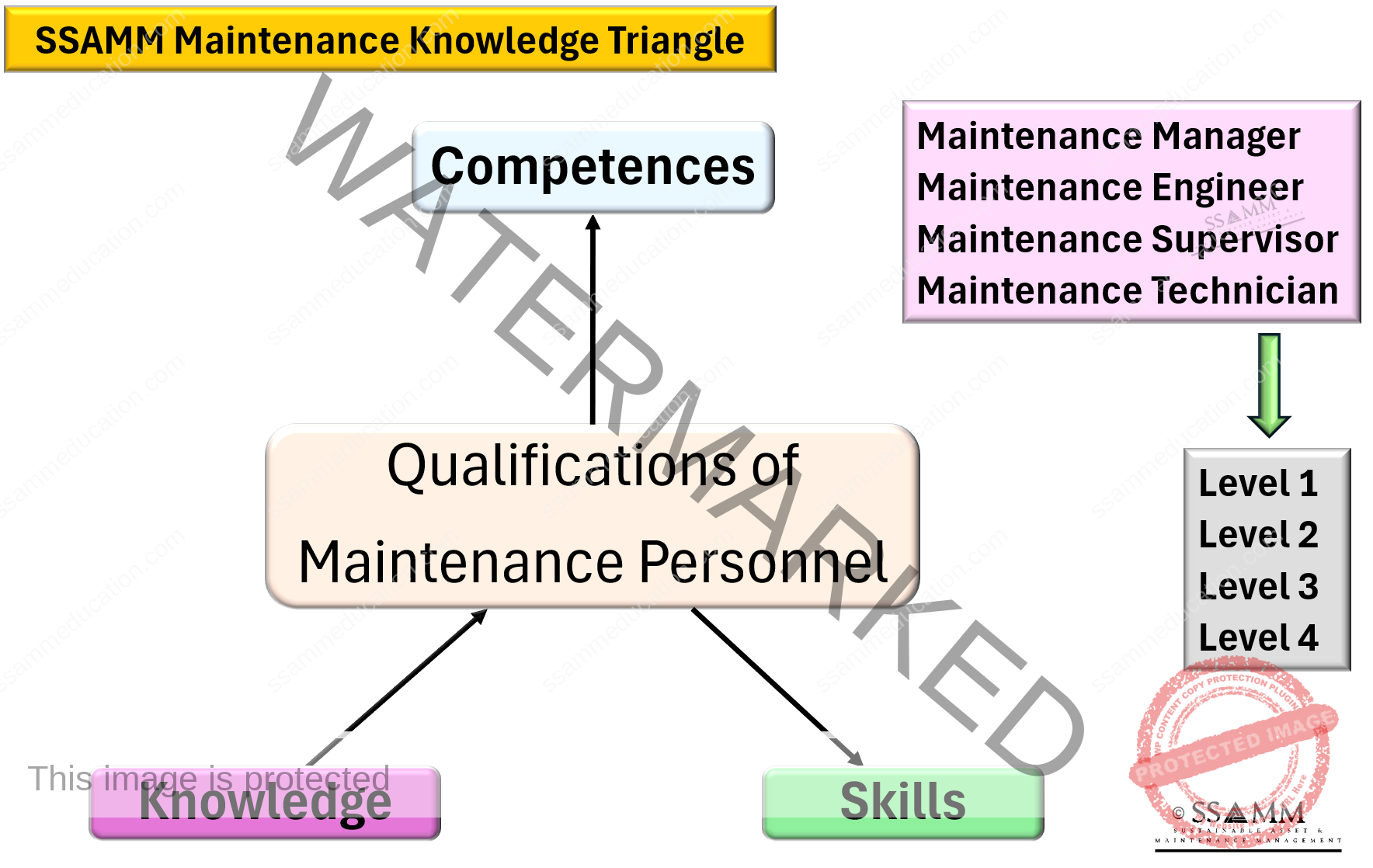

2. Defining Competences, Skills, and Knowledge

The EN-15628:2025 provides clear definitions of competences, skills, and knowledge, which are essential for executing maintenance tasks effectively in modern industrial contexts. This chapter explores these concepts, explains their distinctions, and highlights the role of knowledge as the foundation for developing both skills and competences.

2.1 Competences: The Integration of Knowledge and Skills

Competences are defined as the proven ability to use knowledge, skills, and personal, social, and/or methodological abilities in work or study situations, as well as in professional and personal development. Competences are characterized by the ability to perform tasks autonomously and responsibly. They represent an overarching concept that combines knowledge, skills, and experience with the ability to make informed judgments.

In maintenance management, competences are critical. For example, a maintenance manager requires not only technical skills but also leadership and strategic decision-making capabilities, demonstrating a high level of responsibility and autonomy.

2.2 Skills: Applying Knowledge and Know-How

Skills are described as the ability to apply knowledge and use know-how to complete tasks and solve problems. They can be cognitive (involving logical, intuitive, and creative thinking) or practical (involving manual dexterity and the use of methods, materials, tools, and instruments).

In a maintenance context, skills are indispensable for addressing practical challenges, such as diagnosing and repairing equipment issues. A maintenance technician must be able to apply their knowledge of a machine to effectively perform repairs.

2.3 Knowledge: The Foundation of Competences and Skills

Knowledge is defined as the outcome of the assimilation of information through learning. It encompasses the facts, principles, theories, and practices related to a specific field of work or study. Knowledge serves as the foundation upon which skills are built and competences are developed.

In maintenance processes, knowledge of legal requirements, materials, or techniques is vital. Without this foundational knowledge, a technician or engineer cannot effectively apply skills or develop the competences required for more autonomous and responsible roles, such as those in maintenance management.

2.3 The Essential Role of Knowledge

Knowledge is at the core of both skills and competences. Without a solid knowledge base, it is impossible to develop the practical skills or broader competences necessary for effective decision-making and problem-solving. The EN-15628:2025 emphasizes that knowledge requirements vary by industry and are often linked to specific maintenance processes, as outlined in EN 17007.

The EN-15628:2025 illustrates this relationship with examples, such as how knowledge of “outsourcing” or “spare parts delivery” contributes to skills like “managing maintenance” or “providing external maintenance services.” This demonstrates the direct link between knowledge and the specific tasks required in maintenance roles.

3. The Four Maintenance Roles in the Context of Industry 5.0

4. Maintenance Competence Categories and Knowledge Areas

4.1 Maintenance Competance Categories and Skills in the context of Industry 5.0

The EN-15628:2025 defines a robust set of Maintenance competence categories and associated skills, which are essential for addressing the complexities of modern industrial operations. In the context of Industry 5.0, where human-centric approaches merge with advanced technologies, and Asset & Maintenance Management 5.0, which emphasizes sustainability, resilience, and innovation, these competences and skills form the foundation of effective Maintenance practices. They enable organizations to optimize asset performance, ensure operational reliability, and drive continuous improvement.

Among the 16 Maintenance competence categories, the ability “to manage data” (Competence 9) is particularly significant in the Industry 5.0 landscape. Managing data encompasses organizing, analyzing, and utilizing large volumes of information generated by IoT devices, predictive analytics, and digital twins. This competence ensures that Maintenance professionals can transform raw data into actionable insights, enabling smarter decision-making and more efficient resource allocation.

The associated skills within this category include the use of data management tools, interpreting trends to predict failures, and integrating information from various systems to create a holistic view of asset health. These skills are crucial for organizations striving to implement predictive maintenance strategies, minimize downtime, and align with sustainability goals. By empowering Maintenance personnel to manage data effectively, Competence 9 exemplifies how technology and human expertise can work in harmony to support the overarching principles of Industry 5.0 and Asset & Maintenance Management 5.0.

4.2. Knowledge as the foundation of competence and skills

Knowledge empowers maintenance personnel to contextualize tasks, anticipate issues, and make informed decisions. In the competence-skills-knowledge triangle, knowledge is the foundation upon which the other two elements are built.

Without a robust knowledge base, skills lack depth and precision, and competences cannot reach their full potential. For example, consider a maintenance technician using diagnostic equipment to identify a fault. While the skill to operate the equipment is essential, it is their knowledge of system design, failure mechanisms, and operational parameters that allows them to interpret the diagnostic results and implement corrective actions effectively. Similarly, competences like managing a maintenance team or designing a maintenance strategy require a deep understanding of organizational frameworks, technical standards, and relevant tools to succeed.

Knowledge also plays a critical role in innovation and adaptability. In the rapidly evolving context of Industry 5.0, maintenance professionals must stay abreast of new technologies, methodologies, and best practices. This continuous acquisition of knowledge enables them to integrate cutting-edge tools such as artificial intelligence, predictive analytics, and digital twins into their workflows. As maintenance becomes more data-driven and interconnected, the role of knowledge in synthesizing information and guiding decisions becomes even more vital.

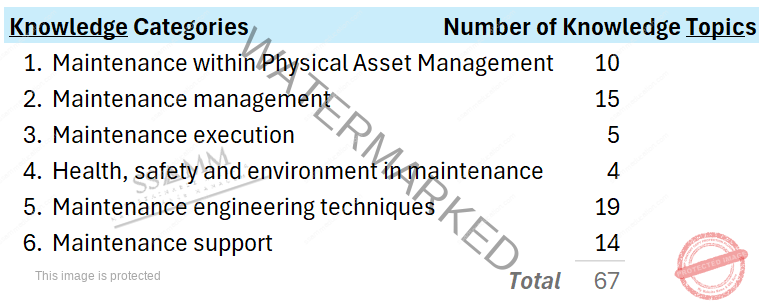

4.3 Six Maintenance knowledge categories

To address the diverse and complex nature of maintenance, the EN-15628:2025 organizes knowledge into six broad categories.

These categories encompass all aspects of maintenance activities and ensure that maintenance personnel at all levels have the theoretical understanding necessary to perform their roles effectively.

-

Maintenance within Physical Asset Management

This category integrates maintenance into the broader context of physical asset management, emphasizing the role of maintenance in asset value creation and sustainability. Key topics include value analysis, economic decision-making, human resource policies, procurement strategies, and integrated logistics support. These elements highlight the strategic importance of maintenance in maximizing asset performance across its lifecycle. -

Maintenance Management

Focused on the organizational and strategic aspects of maintenance, this category includes topics such as maintenance policies and strategies, cost management, contracting, KPI benchmarking, and continuous improvement methodologies. Managers and supervisors rely on this knowledge to align maintenance practices with organizational objectives, ensuring efficiency, reliability, and performance optimization. -

Maintenance Execution

This category addresses the practical aspects of maintenance operations, including preventive maintenance techniques, remote maintenance, scheduling, and digitalization. Topics such as data collection and planning methods ensure that maintenance activities are performed efficiently and effectively, minimizing downtime and resource waste. -

Health, Safety, and Environment in Maintenance

Compliance with health, safety, and environmental regulations is an essential component of maintenance activities. This category covers occupational risk analysis, legislation, and best practices to safeguard the well-being of personnel and protect the environment. It underscores the ethical and legal responsibilities of maintenance professionals in their day-to-day work. -

Maintenance Engineering Techniques

This category provides a deep dive into the technical methodologies and tools that enhance maintenance reliability and effectiveness. Topics include failure mechanism analysis, predictive maintenance, robotics, condition monitoring, and innovative technologies such as digital twins and augmented reality. Engineers and technicians rely on this knowledge to develop advanced maintenance solutions that improve asset performance and reduce costs. -

Maintenance Support

Supporting maintenance operations requires specialized knowledge in areas such as training and certification, CMMS, spare part management, and obsolescence management. This category ensures that maintenance personnel and resources are equipped to handle both current and future challenges, maintaining operational readiness and flexibility.

By defining knowledge within these categories, the EN-15628:2025 ensures that maintenance personnel can build the skills and competences necessary to meet the demands of modern industrial environments. Knowledge is the foundation that allows professionals to adapt to new challenges, integrate emerging technologies, and contribute to the broader goals of sustainability, efficiency, and resilience in maintenance practices.

5. Conclusion: Preparing for the Future with EN15628:2025

The EN15628:2025 represents a milestone in the evolution of Maintenance personnel qualifications, addressing the growing complexity of industrial operations and aligning with the transformative principles of Industry 5.0 and Asset & Maintenance Management 5.0. By integrating sustainability, resilience, and human-centricity into its framework, the standard provides organizations with a structured approach to building competent, skilled, and knowledgeable Maintenance teams capable of meeting current and future challenges.

This standard not only defines the core roles of Maintenance Technician Specialist, Supervisor, Engineer, and Manager, but also emphasizes the importance of aligning competences, skills, and knowledge with strategic goals. Through its focus on advanced technological integration, such as artificial intelligence, predictive maintenance, and digital twins, the EN15628:2025 ensures that Maintenance professionals are equipped to handle the rapid technological changes shaping modern industries.

Furthermore, the EN15628:2025 addresses the demographic challenges facing the Maintenance sector by supporting lifelong learning and providing clear career progression pathways. By aligning with complementary standards such as ISO550XX:2024, EN16646, EN17666, EN17485, and EN13306, it ensures that Maintenance practices are embedded within a broader asset management framework, enhancing organizational resilience and operational excellence.

In the context of sustainability, the standard positions Maintenance as a strategic function that extends the lifecycle of assets, minimizes waste, and reduces environmental impact. Through its emphasis on knowledge categories and competences, the standard provides Maintenance personnel with the tools to contribute meaningfully to an organization’s sustainability objectives, aligning Maintenance practices with the principles of sustainable development.

For a deeper exploration of these principles and their practical applications, we invite readers to consult SAMM, The Maintenance Framework, available on our website chapter funddmental (Click Here ), where the integration of these concepts into actionable strategies is further elaborated.

In summary, the EN15628:2025 is an indispensable tool for organizations seeking to future-proof their Maintenance practices, foster innovation, and build sustainable, resilient, and human-centric operations. It is a call to action for leaders in Maintenance and asset management to align their teams, tools, and strategies with the demands of the modern industrial landscape.