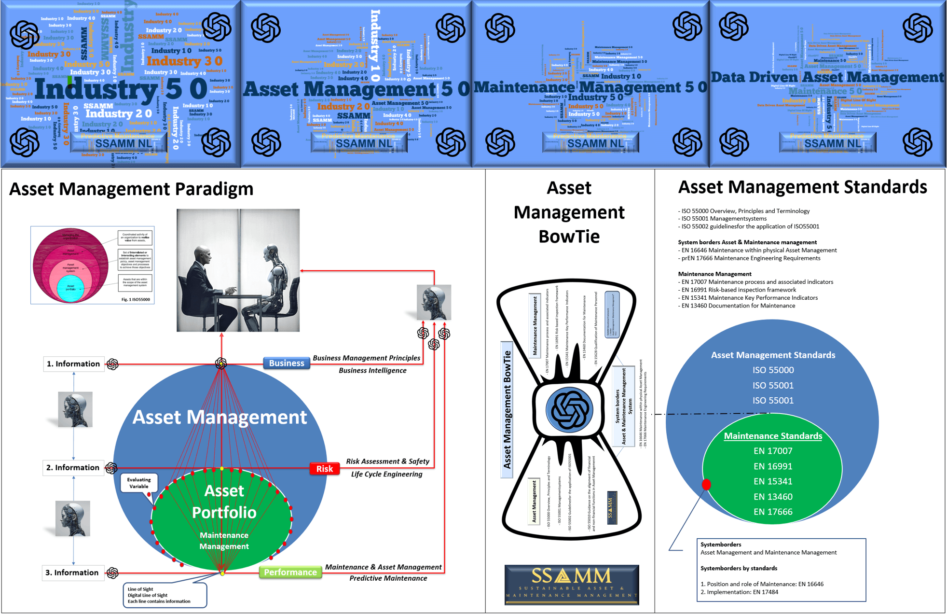

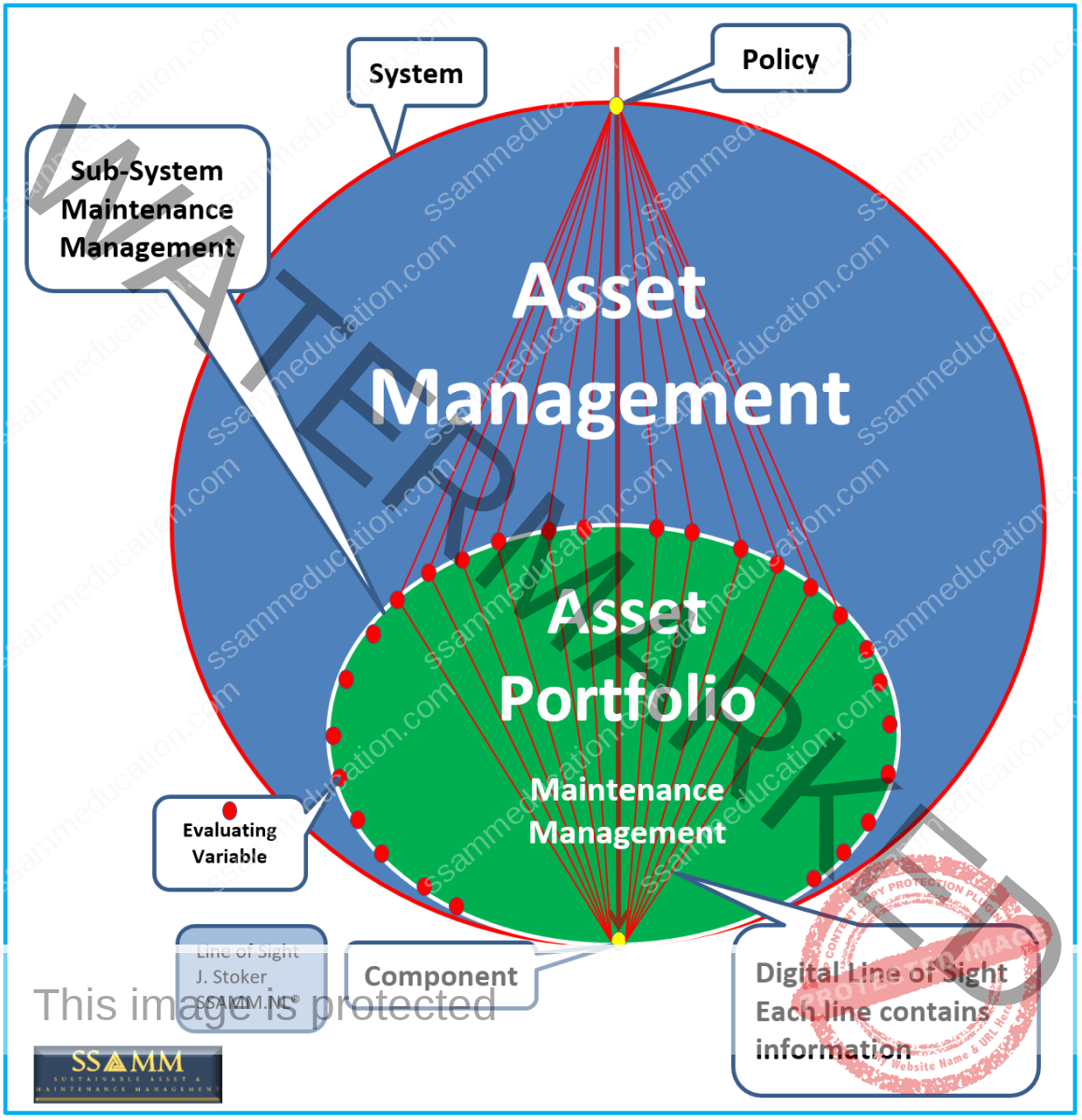

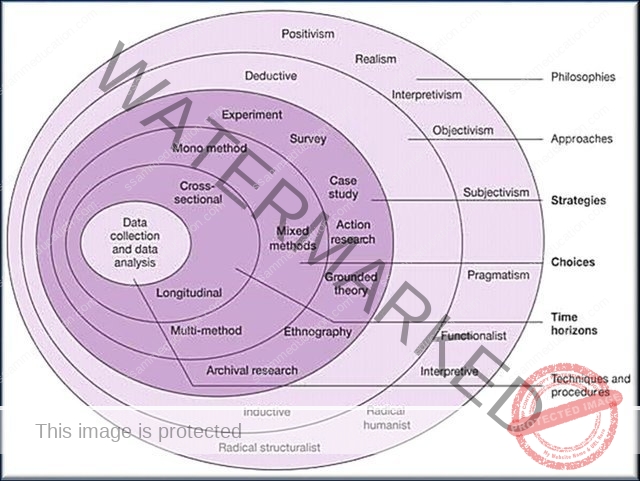

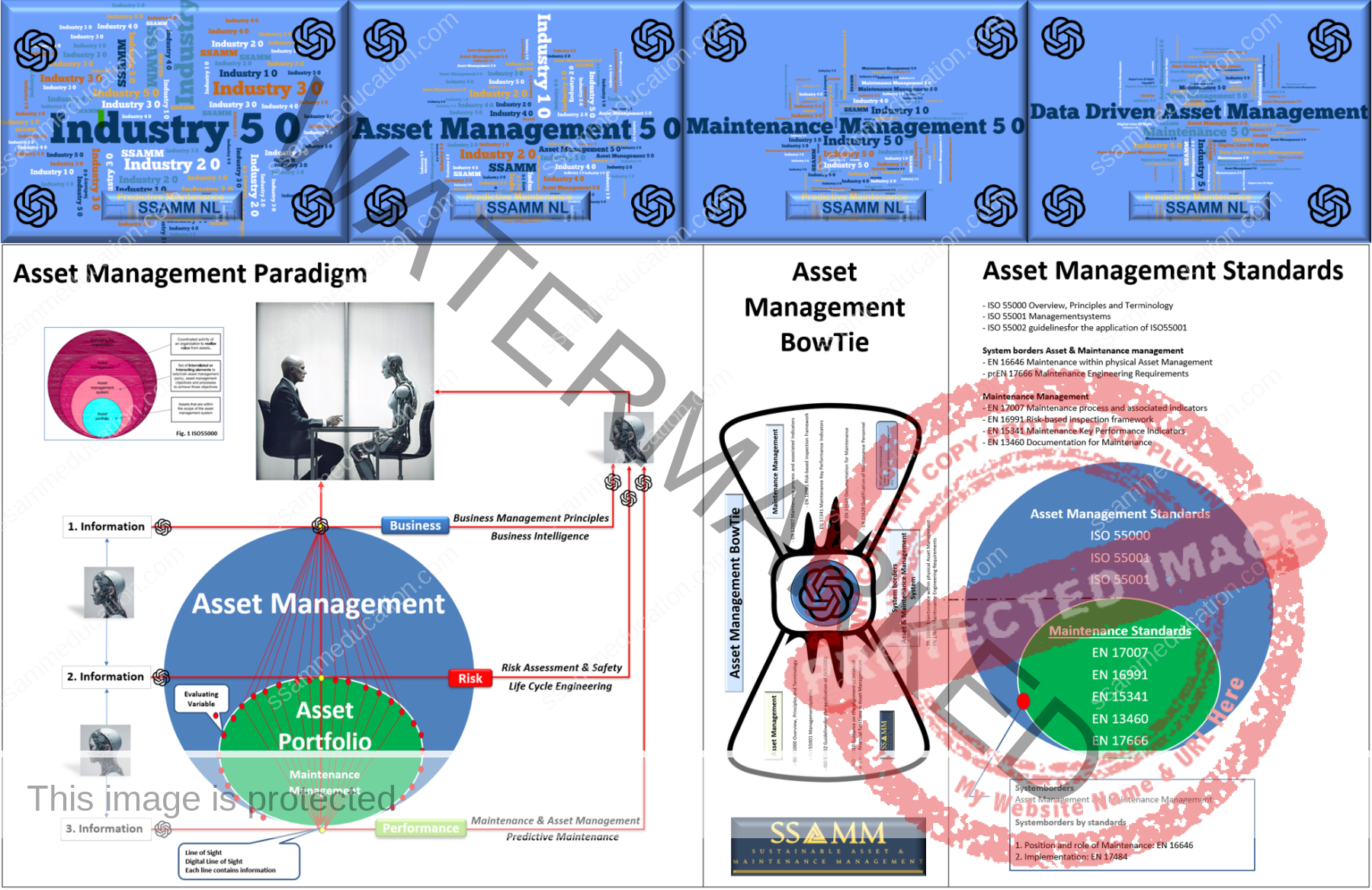

The research is focused on the role of Maintenance Management as one of the four fundamental basic principals of Asset Management as defined in the NEN-ISO 55000. The reason is that the ISO 55000 Maintenance Management regarded as one of the four fundamental pillars of Asset Management. Despite the fact that the standard defines a Asset in such a way that it could be anything, it gives no insight into the structures in which Assets are composed. The research aims to provide insight into this through from the inheritance the three types of element structures (Civil, Building and Industrial Process) adding to the paradigm used by the standard and connecting the policy to the smallest Asset component. This linkage is named “The Line Of Sight” and is based on the analogy with the ” Research Onion “. The following considering describes (shortened) this insight so that the degree of influence of failure by the smallest Asset Component definable and/or quantified and is part of a number of related topics. Derived of this consideration is the SAMP/AMP, the definition of the concept Maincontracting and other related topics and objectives of the research.

- Draft Version: 17 June 2014

- Updated December 3, 2015

- Updated February 8, 2017

- Updated 23 September 2017 (version 1.0)

- Updated 23 March 2018 (Version 2.0)

- Updated 12 November 2020

- Updated 11 September 2023 (Version 2.1)

Countdown SSAMM Academy Module 1

Explore the SSAMM Academy Asset Management and Maintenance Management courses.

Click Here for the Smart information page

Author: Ing. Jan Stoker MSc. MEng. Follow Jan Stoker

When Asset Management

Once an organization is responsible for Assets withing a Portfolio the organization is engaged in Asset Management with the objective create value. Value comes in many forms and can be anything; financial, material, service, estetical, monuments, cultural etc etc. It may be that achieving up-time for example, a data center of the organization is the most important, or producing the most liters of beer, or just the most liters of beer at the lowest possible costs and still achieve the up-time at the lowest energy consumption. But also a pleasant stay, enjoying a safe working environment, the ins tooth like ruins or circular realizing Assets is value creation. It is, thus, to create Assets their value to the organization and its stakeholders. These does not matter what it is an asset. As an asset represents a value can be anything. An asset is a thing, or an entity that has a potential value or actual value. Abstract shapes as knowledge, people, skills, competences … but also buildings, installations in these buildings are also value.

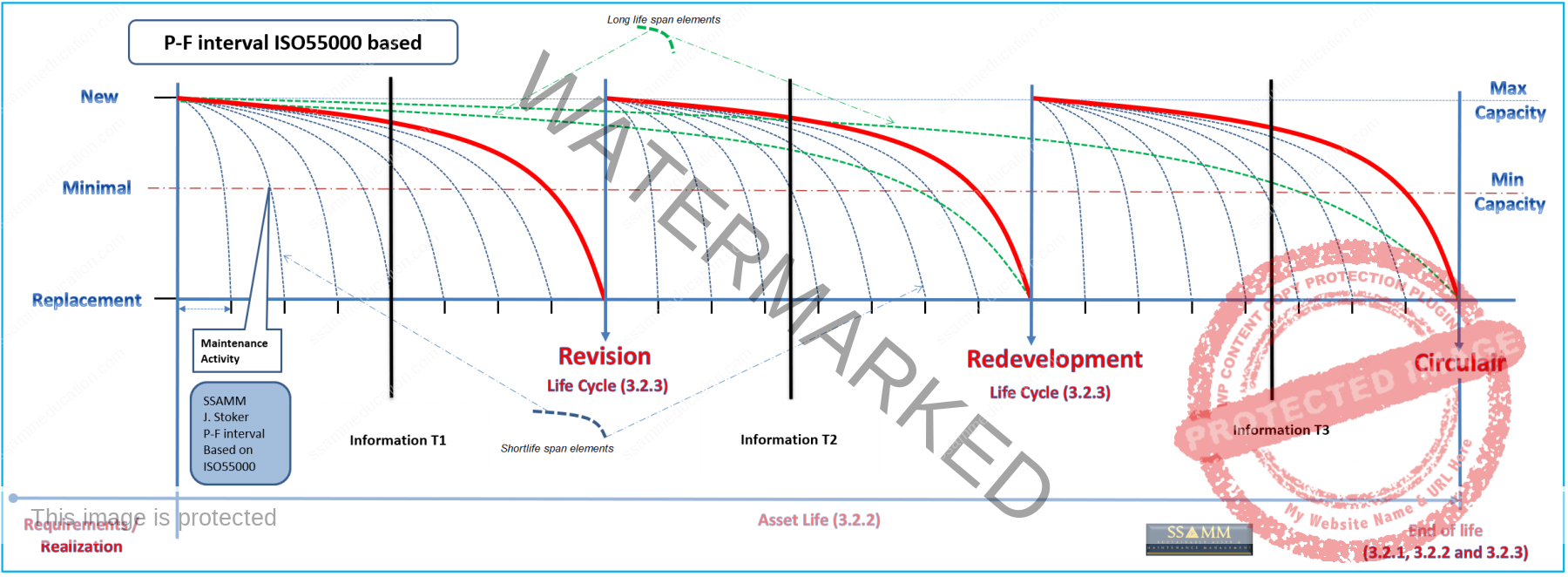

P-F interval Condition related to Lifecycle’s of Assets; ISO55000 Based

1. The Line of Sight Paradigm: Conceptual model and theoretical framework.

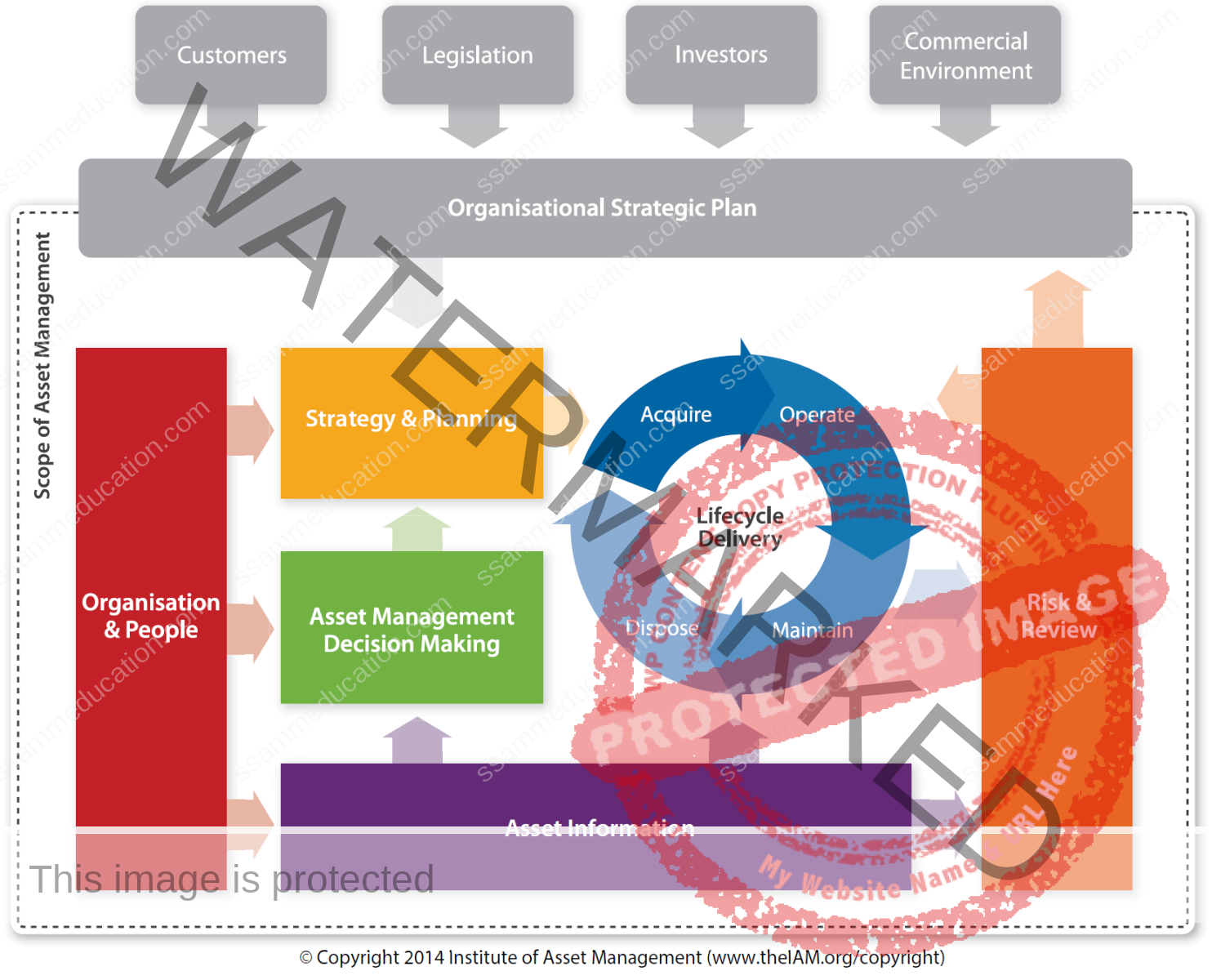

Various institutes defining and formulating views and visually displaying the Asset Management landscape and content. Most well known are the Institute Of Asset Management (IAM) and the Global Forum On Maintenance & Asset Management ( GFMAM ) which works closely with the European Federation of National Maintenance Societies ( EFMNS ) who, for example, defines the competence of the ‘Maintenance Manager’. The Institute of Asset Management (IAM), for example, defines the Asset Management landscape in a conceptual model for the purpose of describing the whole of Asset Management framework. The landscape is divided into six topics that run through 39 processes. The first edition of this landscape was published in Asset Management – An Anatomy November 2011, the second edition was published in March 2014 and the third edition was published in December 2015 (Institute of Asset Management, 2015).

Source: The IAM’s Conceptual Asset Management Model. Herdrukt uit Asset Management – an Anatomy (p.16), The Institute of Asset Management, 2015, Verenigd Koninkrijk, Bristol.

Source : Alignment of the 39 Asset Management Landscape Subjects with six Subject Groups. Herdrukt uit Asset Management – an Anatomy (p.17), The Institute of Asset Management, 2015, Verenigd Koninkrijk, Bristol.

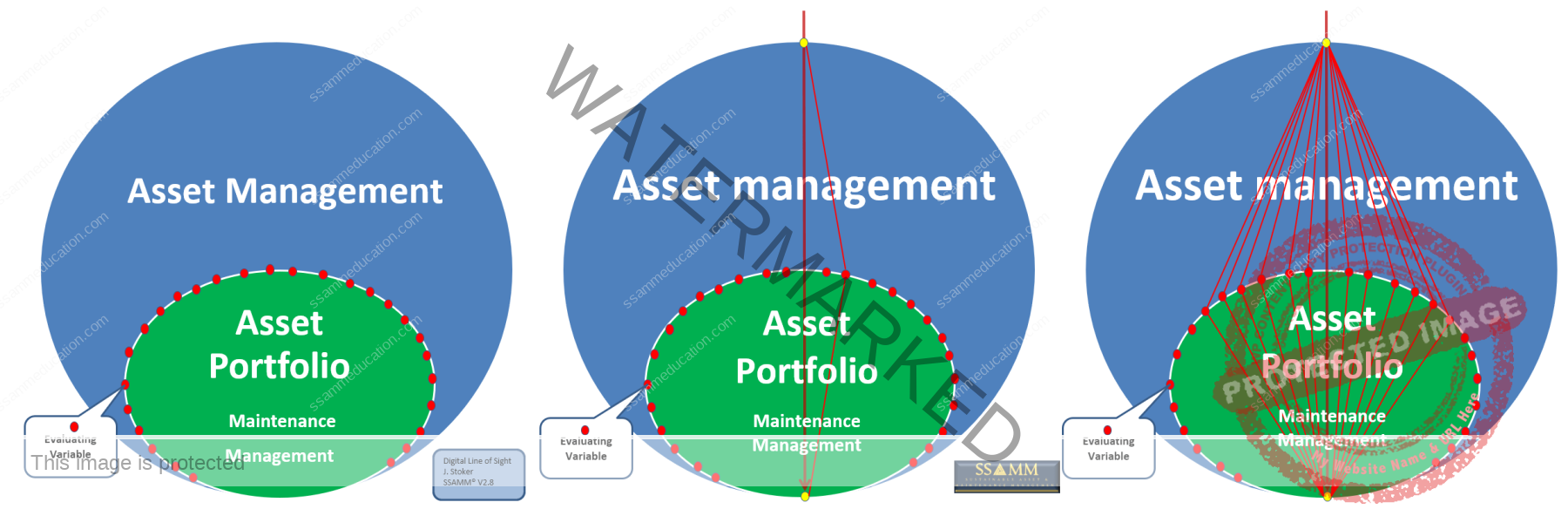

An abstract example is shown in Figure 1 and considered from the system boundary “see” we two phenomena, namely: The Asset and his second of four pillars “Reconciliation” in which the Technical Management & Maintenance in operating under. In the figure this is represented by placing “Alignment” within the asset management so that Alignment is a part of the Asset Management. In this approach, Alignment becomes an integral part of the Asset Management moves along with the circumstances,

This approach implies that there is a connection between the framework (Strategic Asset ManagementPlan and Asset ManagementPlan) which is imposed on the asset management and the smallest part. This connection is represented in the figure by an line and two yellow points that, respectively, the purposes of the asset management and represent the smallest part. This link is “The Line of Sight” or as part of the research “Linking Policy to Maintenance Activity.” The intersection such as that shown in Figure 1, as well as the actual separation between the Asset Management and Technical Management and Maintenance where these are defined as:

- The Asset Management: coordinated all activities of an organization to realize value from Assets.

- The Technical Management & Maintenance: Combination of all technical, administrative and managerial actions during the life cycle of an item intended to preserve or restore in a state where it can perform its required function.

The intersection demarcates the framework the Technical Management and Maintenance has to comply. It specifies, based on the variables for example, what the risks are if components or elements failing, what competencies are required by maintenance employees, what level of service should be delivered or how to deal with the lifetime of elements.

1.1 Evaluating Variables

The red spheres are the Evaluating Variables and are stand-alone variables and their impact on the smallest part of the asset are either prerequisite check that smallest part. These may be variables like risk, asset management plan or competence and are defined in the NEN-ISO 55000. By placing all the variables in the intersection line there is a framework of each variable that influence the function or performance of the component.

Table 1 shows which variables are and are located at the interface between the Asset Management and Technical Management and Maintenance. These 39 (thirty nine) variables that affect the smallest part of the asset.

2. Analogy: The research onion

Such displays have an analogy with the “Research Union” of Sounders, Lewis and Thornhill *. Based on the different layers of the research union science is gained to get insight into the underlying issues that lie at the basis of this methodological choices.

The research interprets the research onion and the way in which the NEN-ISO 55000 explains the relationships between terms, as an analogy, and uses this as a starting point in order to add the various layers to the subjects from which the asset management is built up. The aim is to “peel” the Asset to the smallest component to define as different layers and achieve a conceptual model.

* Sounders, Lewis & Thornhill 2003, Methods of research p.86

2.1 The Asset Management Layers

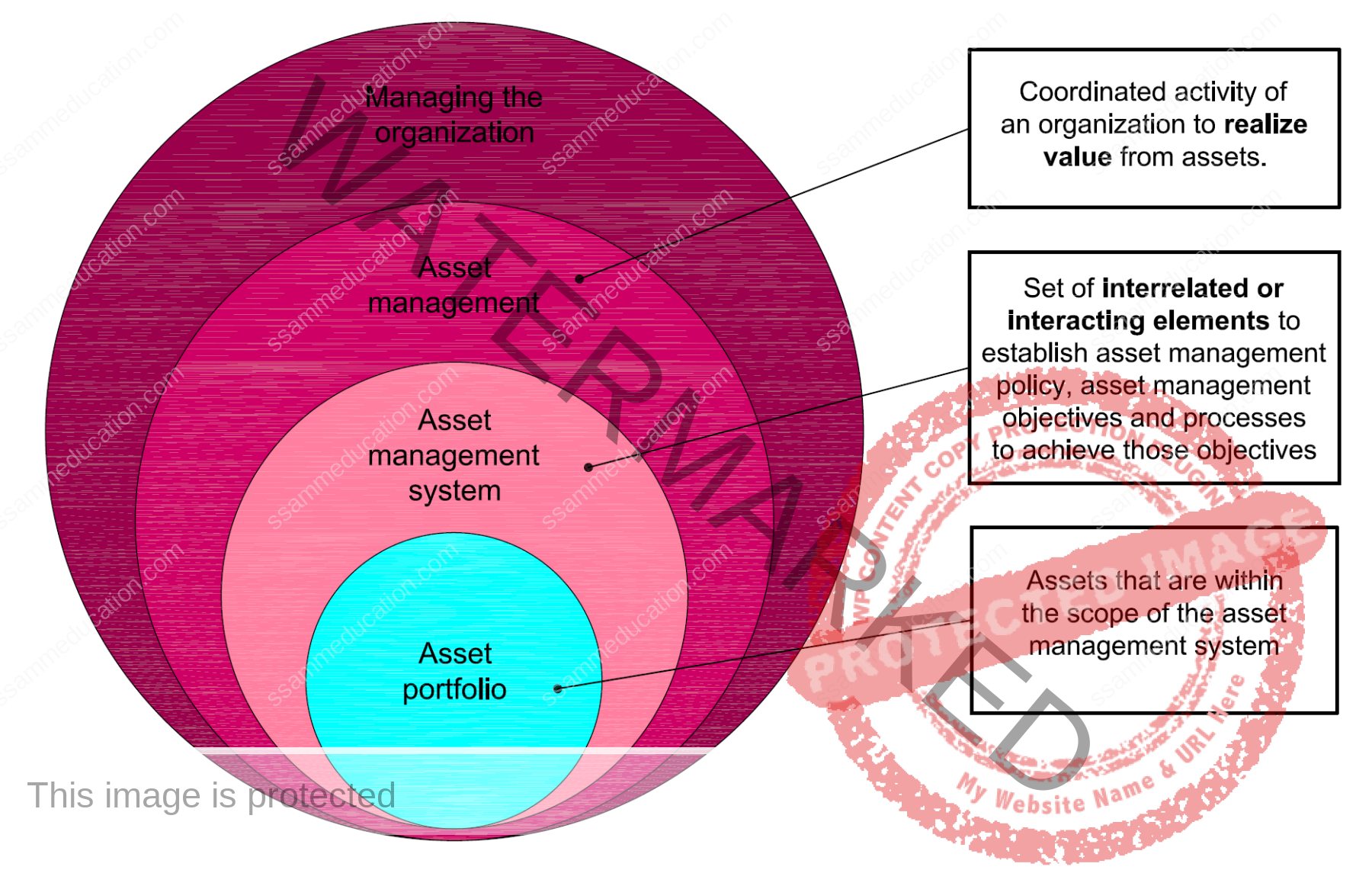

The NEN-ISO 55000 denotes the hand of terms and definitions, the relationship between the different subjects. The NEN-ISO 55000 does this have been recorded on the basis of a framework in which different “layers”.

An example of this is Figure 3 of the standard in which four threads are interpreted that have a relation to each other. It is :

- The management of the organization

- Asset management

- Asset Management System

- Asset Portfolio.

This approach has an analogy, however, the standard provides the research union out three major components that indicate the different layers. These are :

- Visualization of linking policy to Maintenance Activity

- The structure of the Asset portfolio

- The smallest part of an Asset Portfolio

3. Connecting ‘Company Policy with Maintenance Activities’

The link “Policy on Service Activity”, also known as the Line of Sight is an important part of the Asset. The coupling represents that the smallest part is functional performance in the extension of the policy provides delivers its function and performance. Conscious is spoken of here about function and performance.

It is meant that the smallest part of the Asset carries out its function, which may be, for example, ensuring that water flows, cooling takes place, heat is transferred, or otherwise. In performance, it is meant that the component in addition to its function, this is also within a specified standard to take place, for example, with an up-time of 360 days a year, or a quality range of 5% depending on whether the delivered product.

It is envisaged that an organization worth successful and remains in the objectives. Think of making a profit, producing products of a certain quality or to achieve a certain level of aesthetics.

3.1 Connecting Variable to components

Achieving objectives or success in achieving organizational objectives or achieving policy. This can only take place if components (elements and components) provide their functions and their performance as intended. That means that the variables that affect it should be marked or create the conditions to achieve these goals. The figure below represents this situation and give in three steps how the smaller part is attached to the policy.

Figure 4 : Click to enlarge

3.1.1 Deepening ‘The Line of Sight’

In Figure 4.3 the connection is shown between policy and components. In this view, connecting the thirty-nine (39), variables of Table 1, the policy and the component. As indicated in chapter one is the ‘Line of Sight’ visualized by the two yellow dots representing the policy respectively, and component and are connected by “The Line of Sight.”

The present question is what variables or topics include the ‘Line of Sight’. Because of this, the thirty-nine (39) evaluating variables to use in section 1.1 of the interface between the system and the Asset Management Sub-System Technical Management and Maintenance 39 coupled evaluating variables between the policy component.

In this view of the “Line of Sight” is not a “line of sight” but there are actually thirty-nine 39 ‘Line of Sight’s’ that affect the component but also influence each other.

This approach variables can be quantified individually and aggregated as such one value so that a statement can be made about the quality of the Asset Management and Technical Management & Maintenance as a whole.

Figure Line of Sight : Click to enlarge Credits to XPLANE Click Here

3.2 Deepening the Asset portfolio, Asset and Asset type

In the previous section explained how the policy is linked to the smallest part of the asset. This abstract representation is only shown two topics that play, namely the Asset Management which defines under which the Maintenance Management must comply and the Maintenance Management which has to ensure that the part of the asset produces its function and performance.

When the Venn diagram to be translated from the previous section to an Asset Portfolio demarcated by a boundary (system boundary) with within the system boundary three groups of elements ( Civil, Build and Industry * ), this can be represented as a practical situation in the figure 5.

Figure 5 : Click to enlarge

In this figure, “sees” the observer standing on the boundary (system boundary) from point ‘A’ actually three types of element structures with all their components. These are the civil engineering elements starting from the boundary to the building, the Housing and elements of the building (building) itself and the industrial elements of the process that inside that building what actually happens to the primary process. Below is the asset portfolio, briefly described in each element type.

*Terminologie afgeleid van Centraal Bureau Statistiek (CBS) Standaard Bedrijfsindeling (SBI) 2008 versie 2018. Klik Hier

Standing on the boundary civil engineering elements include the building element) and the process (Industrial Elements) what is happening inside the building. This is not necessarily the case because not every industrial process has to take place within a building. With this element structures are provided for all of the elements between the gate and the building. Think of areas, green (grass trees), roads and everything below ground level at the ground of facilities to operate the asset. To decide on the technical quality may refer to the element structure of the NEN 2767 are used and the method NEN 2767.

Within (or on) the civil engineering elements of the Build elements are placed. The Build members are the buildings or structures in which the (industrial) play process. To decide on the technical quality may refer to the element structure of the NEN2767 are used and the method NEN 2767.

Inside the building or structure if present will the (industrial) process instead. This process can be anything such as producing goods or providing services. In order to be able to make a judgment is above functional decomposition is applied to the technical quality, so that the elements and components can be defined.Among other things, failure probability calculations, the technical quality of its adoption of the process so under the “opportunity” can be fixed at the risk of failure and determine what action should be taken.

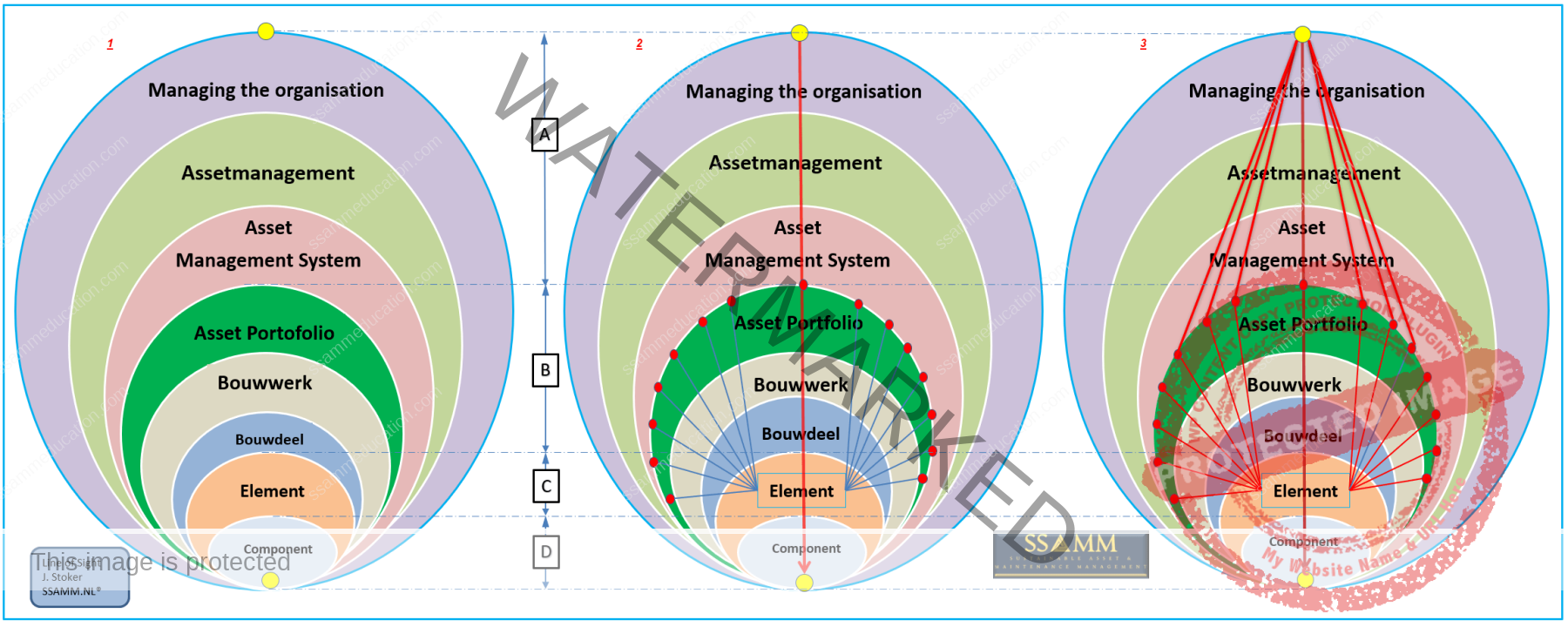

In this “holistic” approach, the Asset management consists dispensed from about 8 layers of the System Asset Management and the (technical), elements of which the sub-system exists, and in which ‘Maintenance Management’ is applied.

The layers are shown in Figure 6. In this approach will find an integrated Asset Management rather than to all the elements that fall within the Asset Management system.

- Managing the organization

- Asset Management

- Asset Management System

- Asset Portfolio

- Civil elements

- Build Elements

- Industrial Elements

- Component

Further deepening can take place by terms and methods from Civil, Build and Industrial process in the sub-system of the Venn diagram. When this is done is created Figure 6. In this figure, floor takes place of the asset portfolio, and in fact are per layer coupled to the variables to the smallest component. Each layer includes an environment in which the smallest part is located and where the policy through the variables establishes the framework and / or influences. In the following representation (Figure 7) are the System Asset Management and the Sub-System Maintenance Management displayed in different layers on a number of levels containing the coupling of the policy to the smaller part and the variables.

Figure 7: Click To Enlarge

Figure 1: Figure 7.1 shows a plurality of layers from which the asset management is built up with two yellow bullets indicated therein, namely: the policy framework, and as a starting point for all the targets and the smallest part of the Asset. The figure shows eight layers on how the organization is built around the portfolio and the manner in which the portfolio is built up.

Figure 2: Figure 7.2 shows as in Figure 3.1 illustrate the correlation between the smallest part, however, the policy and now with connection and the variables that lie at the interface between the organization and the portfolio which must be maintained.

Figure 3: In Figure 7.3, all variables are associated policies to the smallest component. This view can be traced to different variables affect the smallest part through the various layers of the Asset Management of Assets.

3.3 Life Cycles and lifespan within the system Asset Management

For Asset Management within the boundary as a whole or would fully apply the elements within the sub-system maintenance management in an unambiguous manner judged on their technical quality (condition), operation and performance. The importance unambiguously elements of different groups of elements (Civil, Build and Industry) is integral to rule on the technical quality of the asset as a whole. To be able to achieve it at any time “T” during the lifetime of an asset in the life cycle than the result of the technical evaluation must be the same type of information with clear outcome as shown below lifetimes Assets which are composed of Civil, Build and industrial elements.

For Civil and Build are the first steps to put in order to get a clear assessment of the technical quality of components by BS 2767 to include that it is applicable to both structures’ element. In theory, it is possible that the outcome of a NEN2767 inspection of civil engineering and Build elements in the same way interpreted, and if possible, may be aggregated into a single result that represent the technical quality of the civil engineering and Build elements. Unfortunately, complementing industrial elements with the Civil and Build is not possible where the Civil and Build do succeed.

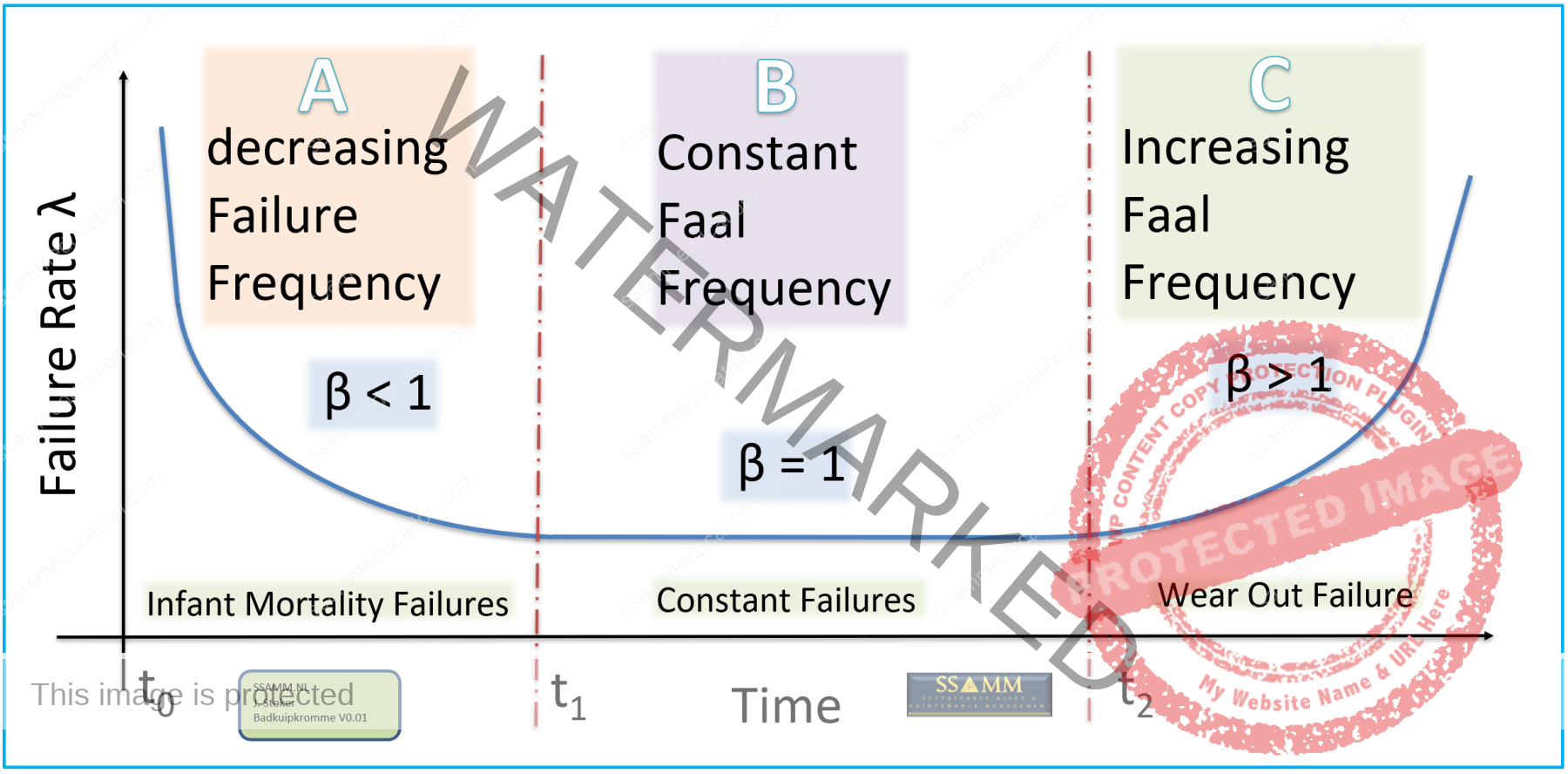

This is because the NEN2767 a qualitative analysis of the technical quality and not necessarily of performance analysis takes place and the performance despite the standard parts that make a statement. Unlike the industrial process where it is common to set the probability of failure fixed deterministic or probabilistic component level and that the degree of technical quality on the base such as using Weibull analysis.

The Weibull analyse can rule on the probability of failure of systems and / or subsystems or whatever type of element structure is analysed. The Weibull may be a possible solution direction to provide the information from the NEN 2767 inspections in a uniform manner from information on failure probabilities so that information on the elementary level is comparable.

This article provides an overview of how infant mortality, normal life failures and wear-out modes combine to create the overall product failure distributions. It describes methods to reduce failures at each stage of product life and shows how burn-in, when appropriate, can significantly reduce operational failure rate by screening out infant mortality failures. The material will be presented in two parts. Part One (presented in this issue) introduces the bathtub curve and covers infant mortality and burn-in. Part Two (presented in next month’s HotWire) will address the remaining two periods of the bathtub curve: normal life failures and end of life wear-out.

The bathtub curve does not depict the failure rate of a single item, but describes the relative failure rate of an entire population of products over time. Some individual units will fail relatively early (infant mortality failures), others (we hope most) will last until wear-out, and some will fail during the relatively long period typically called normal life. Failures during infant mortality are highly undesirable and are always caused by defects and blunders: material defects, design blunders, errors in assembly, etc. Normal life failures are normally considered to be random cases of “stress exceeding strength.” However, as we’ll see, many failures often considered normal life failures are actually infant mortality failures. Wear-out is a fact of life due to fatigue or depletion of materials (such as lubrication depletion in bearings). A product’s useful life is limited by its shortest-lived component. A product manufacturer must assure that all specified materials are adequate to function through the intended product life.

Note that the bathtub curve is typically used as a visual model to illustrate the three key periods of product failure and not calibrated to depict a graph of the expected behavior for a particular product family. It is rare to have enough short-term and long-term failure information to actually model a population of products with a calibrated bathtub curve.

For further reading Click Here

Source: Weibull.com

4. Influence and effect components towards policy

Figures 6 and 7 show how the policy is linked to the smallest part. Figure 6 is used as a paradigm for the research and during the knowledge transfer is called the “Asset Management Onion” by the analogy with the Research onion.

The aim of this paradigm is to make a possible representation of Asset Management and the portfolio that it includes.

The aim is to interpret the relationship between policy and the smallest part that is considered one direction in the representation but are actually two directions, namely :

- Frame to Maintenance Management ( Top to Down )

- Influence on policy ( Benden to Top )

4.1 Framework

Arguing with frame means that the policy under, which includes the Maintenance Management to meet. The framework is often documented and is trapped in organizational structures, processes and explicitly named in the ISO 55000 in the triptych:

- Asset Management

- Strategic Asset Management Plan

- Asset Management Plan

In accordance with the definition of the asset management, which is defined in accordance with the NEN-ISO 55000 as:

Asset Management

Coordinated activity of an organization to realize value from assets

- Note 1 to entry : Realization of value will normally involve a balancing of costs, risks , opportunities and performance benefits.

- Note 2 to entry : Activity can also refer to the application of the elements of the asset management system.

- Note 3 to entry : to entry: The term “activity” has a broad meaning and can include, for example, the approach, the planning, the plans and their implementation.

Asset management is aimed to operate that part of the organization so that the framework to create value is actually made. This means defining and formulating the framework that lays down which services are to be provided by the asset functions.

In accordance with the definition of the SAMP, which is defined in accordance with the NEN-ISO 55000 as:

Strategic Asset Management Plan**

Documented information that specifies how organizational objectives are to be converted into asset management objectives, the approach for developing asset management plans, and the role of the asset management system in supporting achievement of the asset management objectives

- Note 1 to entry : A strategic asset management plan is derived from the organizational plan.

- Note 2 to entry : A strategic asset management plan may be contained in, or may be a subsidiary plan of, the organizational plan.

The SAMP is a document for the entire portfolio. The SAMP objectives are concretely defined by the organization to develop strategies so that activities can be operationalized

In accordance with the definition of the asset management plan that is defined in accordance with the NEN-ISO 55000 as:

Asset Managementplan

Documented information that specifies the activities, resources and timescales required for an individual asset , or a grouping of assets, to achieve the organization’s (3.1.13)asset management objectives

- Note 1 to entry : The grouping of assets may be by asset type, asset class, asset system or asset portfolio.

- Note 2 to entry : An asset management plan is derived from the strategic asset management plan.

- Note 3 to entry : An asset management plan may be contained in, or may be a subsidiary plan of, the strategic asset management plan.

The Asset Management Plan is an extension and deepening of the SAMP and is described specifically what is expected of the individual asset.

** Source: ISO 55000; The author thanks the NEN for his permission to publish the terms and definitions of the used standards

4.2 Impact on Policy

At the moment Asset Management, Strategic Asset Management Plan and Asset Management Plan are formulated implies even so that the functional and performance requirements of the smallest part of the asset are defined.

Maintenance Management it selve is focused on during the time the asset management this requires that parts of the asset fullfill the functional specification and performance. In this situation, objectives are fully achieved by the organization. This situation can be represented as a situation where failures does not exist and so there is no downtime, no distortions that reduce the profit or increase risks and asset components complete their life cycle. The ideal situation.

Unfortunately, this is a theoretical view and not reality. The reality is that Asset parts will fail and thus affect the objectives. Not performing in accordance with the policy means that the policy is undermined by risks whatsoever as a result.

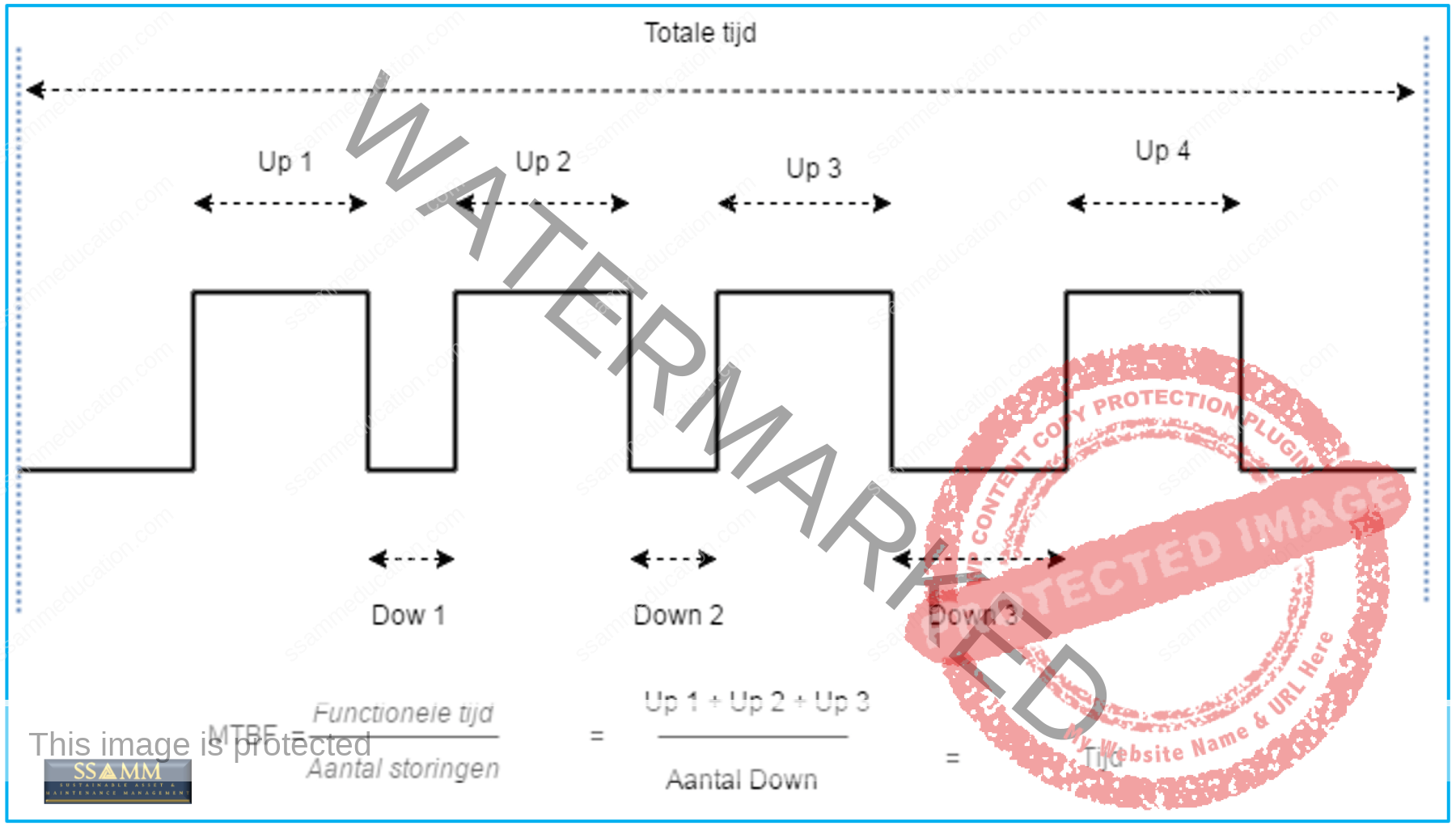

There are several different types of impact or failures that can affect the policy. The most well-known is the downtime as a part of the Mean Time Between Failures (MTBF) when it comes out of pre-defined values. MTBF refers the mean time the asset is available to create value. A simple representation of MTBF is shown in the following figure in which the asset creates value at the time that this “Up” and no value delivering if it is “Down”.

- NEN-ISO 55000 Asset Management – Overview, principles and terminology

- NEN-EN 13306 : Maintenance Terminology

- NEN-ISO Guide 73 , Risk Management – Vocabulary

- NEN-ISO 31000 Risk management Principles and Guidelines

- NEN-ISO / IEC 31010 Risk Management – Risk Assessment Techniques

- NEN-ISO 37500 Guidance on Outsourcing

- NEN- EN 13460 Maintenance – Documentation for Maintenance

- NEN- EN 16646 Maintenance – Maintenance within physical Asset

- Bibliography : Click Here

The author thanks the NEN for his permission to publish the terms and definitions of the used standards.

There are also other examples when MTBF is not an issue. Think of for example monumental objects, ruin’s or monumental cityscape’s who actually provide no production but contribute significantly to value creation. This (secondary) value creation occurs through the processes taking place around such asset types and / or only have the right to exist by the presence of these asset types.

For the explanation of the “Line Of Sight”, according to the paradigms as shown in the paragraphed 3.1 and 3.2, this is considerd from failing Asset parts where MTBF are present. The direct linking of the policy to the smallest component affects the MTBF policy and thereby affect respectively :

- Asset management

- Strategic Asset Management Plan (SAMP)

- Asset Management Plan (AMP)

The MTBF affected the Asset Management by the coordinated activities of an organization to realize value apparently did not comply or fail unless the MTBF foreseen or calculated. These are specific to the “coordinated” activity nearby the asset of an organization which, for example costs and benefits or risks and finances are not balanced.

The MTBF influenced and / or undermined the Strategic Asset Management Plan (SAMP) of the Asset Portfolio’s because the (documented) information on which the SAMP’s are based is not constant in the situation that the MTBF is different than anticipated. As a result, organizational objectives are not achieved, and are Asset Management Plan defined incorrectly.

Most tangible impact the MTBF of the Asset Management Plan. Failure has direct effect on the individual Asset or Asset group making the asset management objectives or not be achieved in part. An individual asset can be a building or group of buildings that fail to function or performance which makes the value creation stagnates in any form.

5 Sumarisation ‘Line of Sight’

The International Organization for Standardization (ISO) has established a myriad of standards that guide industries and organizations worldwide. Among these is the ISO 55000 series, which provides guidelines, principles, and terminology related to asset management. Central to this series is a concept referred to as the “line of sight” between organizational objectives and asset management activities. This concept is essential in understanding how asset management aligns with the broader strategic intentions of an organization.

5.1 Line of Sight Defined

Derived of the fourth fundamental principal ‘Alignment’ (ISO55000 Paragraph 2.4.2) The line of sight, as conceptualized in ISO 55000, describes the clear and unobstructed connection between an organization’s asset management objectives and its strategic organizational objectives. Essentially, it ensures that every asset management decision and activity can be traced back and justified in terms of its contribution to the achievement of the organization’s strategic intents.

Accoring the ISO55000 Alignment:

Alignment: Asset management translates the organizational objectives into technical and financial

decisions, plans and activities. Asset management decisions (technical, financial and operational) collectively enable the achievement of the organizational objectives.This includes:

- the implementation of risk-based, information-driven, planning and decision-making processes

and activities that transform organizational objectives into asset management plans- the integration of the asset management processes with the functional management processes

of the organization, such as finance, human resources, information systems, logistics and

operations;- the specification, design and implementation of a supporting asset management system.

See also The Institute of Asset Management ‘Asset managemen an Anatomy Paragraph 2.3.2

5.2 Importancy Line of Sight

-

Alignment with Organizational Goals: The line of sight ensures that all asset management activities are in direct support of the organization’s mission, vision, values, and strategic objectives. This helps organizations avoid unnecessary investments or expenditures that don’t align with their overall strategy.

-

Optimized Decision-making: By maintaining a clear line of sight, decision-makers can prioritize investments, maintenance activities, and other asset management initiatives that most directly contribute to strategic objectives. This fosters a culture of value creation and ensures optimal resource allocation.

-

Stakeholder Assurance: Stakeholders, both internal and external, can be assured that resources are being used wisely and in a way that supports the long-term health and success of the organization.

5.3 Establishing and Maintaining the Line of Sight

-

Strategic Planning: Organizations should start by having a clear strategic plan in place, outlining their broader objectives.

-

Asset Management Policy: This policy should translate the organizational objectives into tangible asset management goals, thus beginning the process of establishing a line of sight.

-

Asset Management Strategy: Derived from the policy, the strategy provides a roadmap of how the goals outlined in the policy will be achieved. It will typically encompass lifecycle management, risk management strategies, and performance measures.

-

Asset Management Plans: These are more granular, detailing how the strategies will be implemented for specific asset classes or individual assets. This is where the “rubber meets the road” in terms of tangible actions.

-

Continuous Review: Establishing a line of sight isn’t a one-time event. It requires regular reviews and revisions to ensure alignment as organizational priorities and external conditions change.

5.4 Puting it together

The concept of the line of sight as defined by ISO 55000 is a pivotal one. It bridges the gap between high-level strategic objectives and day-to-day asset management operations, ensuring cohesion, alignment, and optimized resource use. By maintaining a strong line of sight, organizations can achieve greater efficiencies, value creation, and stakeholder satisfaction in their asset management endeavors.

6. From the Line of Sight Towards the Digital Line of Sight in the Industry 5.0 timeframe.

With the advent of Industry 5.0, there’s an increasing emphasis on integrating digital technologies and aligning their functionalities with Human-Centered design and sustainability to ensure resilience in industries. One such concept that has emerged at the confluence of these transitions is the “Digital Line of Sight.” The author seeks to elucidate the significance of the Digital Line of Sight in the context of the ISO55000, and how it’s poised to revolutionize Asset & Maintenance Management across strategic, tactical, and operational levels.

6.1 About Industry 5.0

The European Commission, as of 2021, has been instrumental in setting the tone for the future of industrial and manufacturing landscapes, not just within Europe but for global standards as well. Among these evolving paradigms is Industry 5.0, which represents a significant shift in how industries function, putting humans at the forefront of technological innovation.

6.1.1 Defenition Industry 5.0

Industry 5.0 is defined by the European Commission as the next phase in the evolution of the industrial sector, post-Industry 4.0. While Industry 4.0 focused on digitalization, automation, and the utilization of cyber-physical systems, Industry 5.0 emphasizes the collaboration between humans and machines. This is about utilizing advanced technologies to augment human capabilities rather than replace them, fostering a more human-centric approach to manufacturing and production.

6.1.2 Key Topics Industry 5.0

Industry 5.0, often viewed as the next phase after Industry 4.0’s digital revolution, places a strong emphasis on human-machine collaboration and other aspects that impact the production process and the broader socio-economic ecosystem. While interpretations of Industry 5.0 may vary across sources, three key topics frequently emerge in discussions about this evolutionary step:

6.1.2.1 Human-Machine Collaboration:

-

- Collaborative Robots (Cobots): Different from conventional robots designed for automation, cobots are designed to work side-by-side with humans without being isolated in cages. They can assist in various tasks, ensuring efficiency and safety, while allowing for more flexibility in the production line.

- Enhanced Workspaces: Technologies like Augmented Reality (AR) and Virtual Reality (VR) are becoming tools for workers, providing real-time information overlays, aiding in design, and assisting in remote collaboration or maintenance tasks.

- Decision-making Augmentation: Advanced AI systems can process vast amounts of data swiftly, offering insights and analyses. Instead of replacing human decision-makers, these tools augment their capabilities, allowing for more informed decisions based on a combination of human judgment and machine-derived insights.

6.1.2.2 Customization and Personalization:

-

- From Mass Production to Mass Customization: Due to the increased flexibility afforded by closer human-machine collaboration and more responsive manufacturing technologies, there’s a shift from mass production to mass customization. This allows industries to cater to individual customer preferences more efficiently.

Consumer’s Role in Production: As customization becomes more prevalent, consumers may play an even more direct role in the design and production processes, using platforms that allow them to tailor products or services to their precise needs.

6.1.2.3 Sustainability and Circular Economy:

-

- Resource Efficiency: Industry 5.0 emphasizes the sustainable use of resources, minimizing waste, and optimizing the entire product lifecycle for environmental efficiency.

- Circular Production Models: Embracing the principles of the circular economy, Industry 5.0 underscores the importance of designing products for longevity, recyclability, and reuse. This holistic approach ensures that products, once they reach the end of their lifecycle, can be reintegrated into the production cycle, minimizing waste and environmental impact.

- Sustainable Work Environments: Beyond the product lifecycle, there’s also an emphasis on creating sustainable work environments. This encompasses not only environmental factors but also the well-being of employees, promoting inclusivity, diversity, and equitable growth.

In essence, Industry 5.0 is about blending the best of human capabilities (creativity, critical thinking, emotional intelligence) with advanced technologies to create more sustainable, personalized, and efficient production models. The goal is not only economic growth but also social progress and environmental responsibility.

6.2 Introduction: The Digital Line of Sight (DLoS)

The Digital Line of Sight (DLoS) can be described as the seamless integration of digital technologies with business processes, assets, and strategies. It emphasizes the transparent and real-time flow of information across the asset lifecycle, promoting visibility, traceability, and connectivity from asset strategy formulation to its execution and maintenance.

6.3 The Catalyst: Industry 5.0

Industry 5.0 represents a shift from automation-dominated manufacturing and processes to a more human-centric and sustainable model. At its core, Industry 5.0 emphasizes:

- Sustainability: Adopting processes that reduce wastage and are environmentally benign.

- Resilience: Ensuring industries are equipped to handle disruptions efficiently.

- Human-Centric: Positioning humans at the center of technological advancements, ensuring a harmonious relationship between machines and their human operators.

6.4 The DLos and ISO55000 in Asset & Maintenance Management

ISO55000 is a family of standards dedicated to asset management. Under the umbrella of ISO55000, the DLoS ensures:

- Transparent tracking and management of assets.

- Enhanced decision-making through real-time data.

- Streamlined maintenance processes, reducing downtime and increasing productivity.

6.5 Impact of DLos across Different Levels

Strategical Level

- Alignment with Objectives: DLoS ensures that asset management strategies align with overarching business objectives by offering real-time data insights and promoting informed decision-making.

Tactical Level

- Optimization of Resources: By providing a continuous flow of information, DLoS helps in better allocation and utilization of resources, ensuring that assets are maintained efficiently without undue resource strain.

Operational Level

- Enhanced Efficiency: On the ground, the DLoS aids in identifying bottlenecks, ensuring that maintenance activities are carried out without disruptions, and assets are utilized to their fullest potential.

6.6 DLos: Embodying the principles of Industry 5.0

-

Sustainability: By promoting efficient asset management, DLoS ensures that assets have a longer lifecycle, reducing wastage and promoting sustainability.

-

Resilience: With the ability to quickly identify and rectify issues through the DLoS, industries become more resilient to potential disruptions.

-

Human-Centric: DLoS ensures that technologies are geared towards easing the human workload, ensuring that maintenance activities are more intuitive and less burdensome.

The Digital Line of Sight, as articulated within the framework of ISO55000, stands at the forefront of Industry 5.0 transformations in asset and maintenance management. By embracing DLoS, industries can ensure that they are not just more efficient, but also more sustainable, resilient, and human-centric. The synergy of DLoS and Industry 5.0 principles is poised to redefine the way industries operate, ensuring a future that is both technologically advanced and intrinsically human.

Tags: Newsletter 1