Publication reference

Title: The Value Chain Standardization Line Of Sight

Author: Benjamin Stoker

Publisher: SSAMM (Click Here)

Publication platform: SSAMM Academy – ssammeducation.com

ISBN/EAN: 978-90-8339-892-1

This restricted web article provides an overview and selected extracts from the publication The Value Chain Standardization Line Of Sight (ISBN/EAN 978-90-8339-892-1). It is made available exclusively to registered SSAMM Academy clients as part of their personal, non-transferable licence.

© 2024 Stoker / SSAMM. All rights reserved.

This content is provided under a personal, non-transferable licence. Unauthorised sharing of logins, screenshots, files or copies (in whole or in part) is not permitted

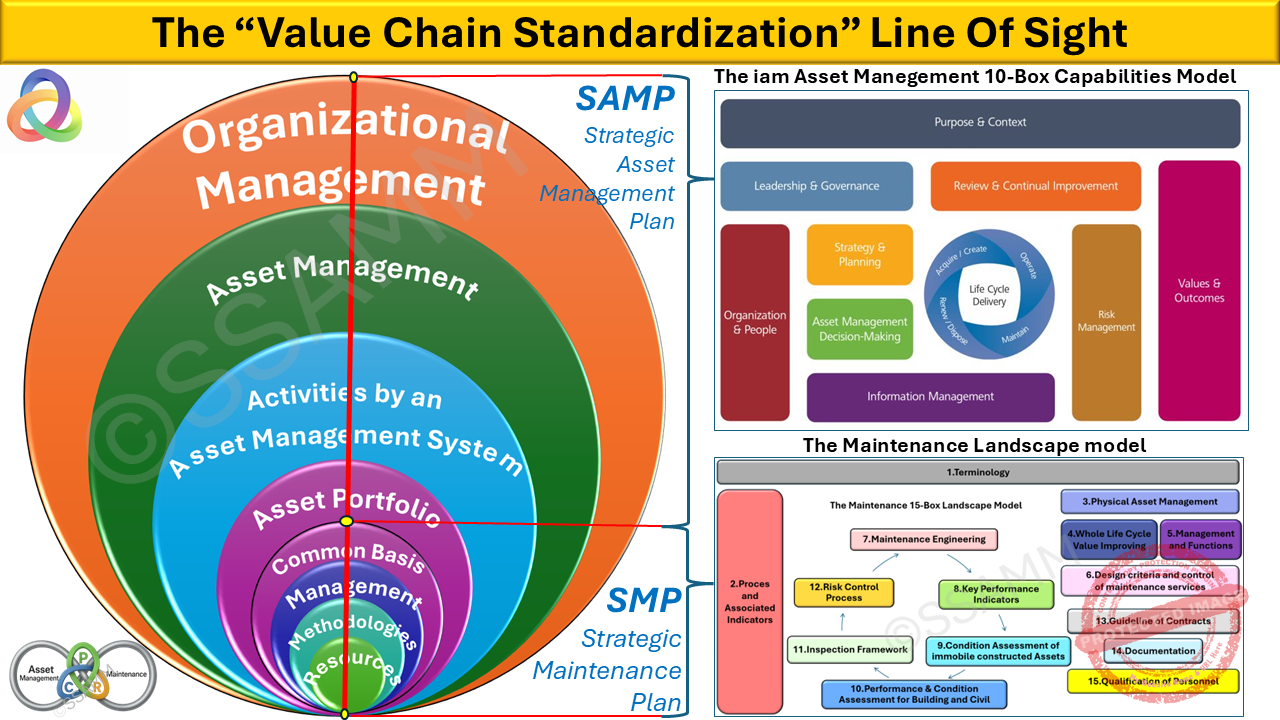

This publication presents a condensed version of The Value Chain Standardization Line Of Sight, an integrated model for aligning the ISO 55000:2024 Asset Management standards with the CEN/TC 319 maintenance standards across the entire Asset & Maintenance Management (A&MM) value chain.

In many organisations, these standards are present but used in fragments: ISO 55001 and SAMPs at strategic level, and selected EN standards, legacy contracts and local practices at operational level. What is often missing is a clear, auditable line of sight that connects organisational objectives and public value to maintenance decisions and tasks – and brings feedback from the field back to policy and strategy.

The Value Chain Standardization (VCS) Line of Sight addresses this gap. It treats ISO 55000:2024 and CEN/TC 319 as one coherent normative architecture and organises them into a layered model that spans from organisational management, via the Asset Management System (AMS) and the Strategic Maintenance Policy (SMP), down to maintenance processes, methodologies, contracts, documentation and competence. The model is further integrated with the P–C–R Trefoil decision logic, the A&MM Lemniscate and the Maintenance Framework. This summary outlines the core ideas, the main architectural elements and the implications for roles, governance, digitalisation and maturity, without reproducing the full text of the original article.

Read the full page version Click Here (Inlog Needed) Application for VCS inlog Click HereDownload Publication The VCS Line of Sight Click Here

- Concept draft Asset Management Union Juni2 2014 Click Here

- Publication AM Union & Digital Line of Stight December 2015 Click Here

- Concept A&MM Lemniscate and VCS 2023

- Fisrst draft VCS -Line of Sight 19 December 2024

- Updated 17 February 2025

- Published 2 October 2025

- Published SSAMM Social Media platforms November 2025

SAMM, First Edition Click Here Keynote Āpōpō Congres 2026 Follow Sustainable Asset Management for latest updates

Countdown SSAMM Academy Module 1

Explore the SSAMM Academy Asset Management and Maintenance Management courses.

Click Here for the Smart information page

Author: Ing. Jan Stoker MSc. MEng. AMCP. CFAM. Follow Jan Stoker

1. Purpose and context of this summary

Asset Management and Maintenance Management have matured rapidly in the past decade. The ISO 55000:2024 series offers a robust framework for Asset Management Systems, while the CEN/TC 319 standards provide a rich set of concepts, processes, methods and competence frameworks for maintenance. Many organisations have adopted at least parts of this normative landscape, often driven by certification, regulatory expectations or internal improvement programmes.

Yet, when looking at practice, a recurring pattern emerges. Standards are present, but they operate as islands. ISO 55001, SAMPs and high-level policies live at the top of the organisation; at the bottom, maintenance is still largely steered by local templates, legacy contracts, individual experience and partial use of EN standards. Between these levels, the line of sight is often blurred. It is hard to trace how organisational objectives and risk appetite influence maintenance concepts, inspection plans or work orders, and equally hard to aggregate maintenance data into meaningful insight for strategy, assurance and long-term affordability.

This summary sets out the core ideas of The Value Chain Standardization Line Of Sight, which proposes Value Chain Standardization as a response to this fragmentation. It introduces a structured way of viewing the ISO 55000:2024 and CEN/TC 319 standards as a single normative architecture and explains how this architecture can be used to design, govern and continuously improve an A&MM value chain that is both standardised and capable of learning.

The full article develops these ideas in depth, with detailed mappings, role-based perspectives and an implementation roadmap. The present text aims to give the reader enough structure and insight to judge whether the approach resonates with their context, and to encourage them to explore the complete publication.

Connecting the landscapes

2. From fragmented standards to Value Chain Standardization

The starting point of the work is the observation that value, in the ISO 55000 sense, is a chain outcome. Assets only create value when a sequence of activities – from concept and design through construction, operation, maintenance, renewal and disposal – is coordinated in a way that supports organisational objectives and societal expectations.

If value is the result of a chain, it follows that the standards governing Asset Management and Maintenance should be treated as elements of a value chain architecture, not as separate documents to be used opportunistically. In many organisations this is not yet the case. ISO 55001 may structure the AMS, while isolated applications of EN 13306, EN 17007, EN 17666, EN 15341 or EN 16991 structure specific maintenance processes or tools. The result is local optimisation rather than systemic coherence.

Value Chain Standardization is introduced as the deliberate alignment of language, processes, roles, methods, data structures and competence requirements across the entire A&MM value chain. It aims to turn a patchwork of standards and practices into one navigable architecture. Instead of asking “which standard do we use where, if at all?”, the VCS perspective asks “how do we organise the standards we already have into a single, transparent line of sight from strategy to execution and back?”

The VCS Line of Sight takes the ISO 55000 logic of value, life cycle and alignment as its starting point and combines it with the CEN/TC 319 maintenance architecture. It does so in a way that is compatible with existing International and European standards, but that makes their mutual relationships explicit and discussable.

The Maintenance landscape Model

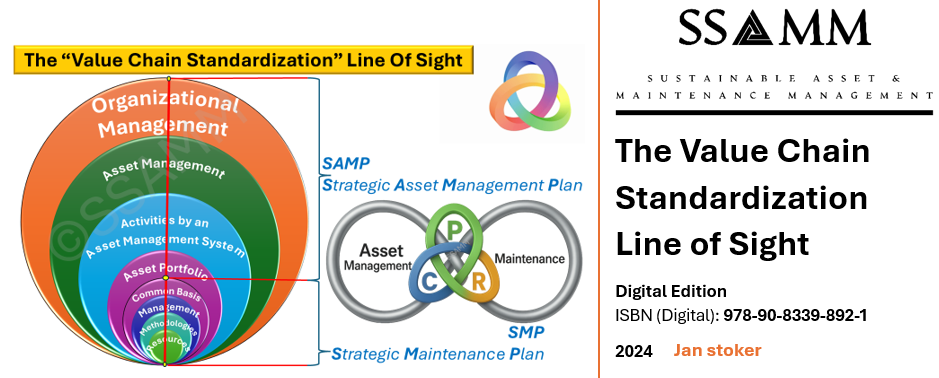

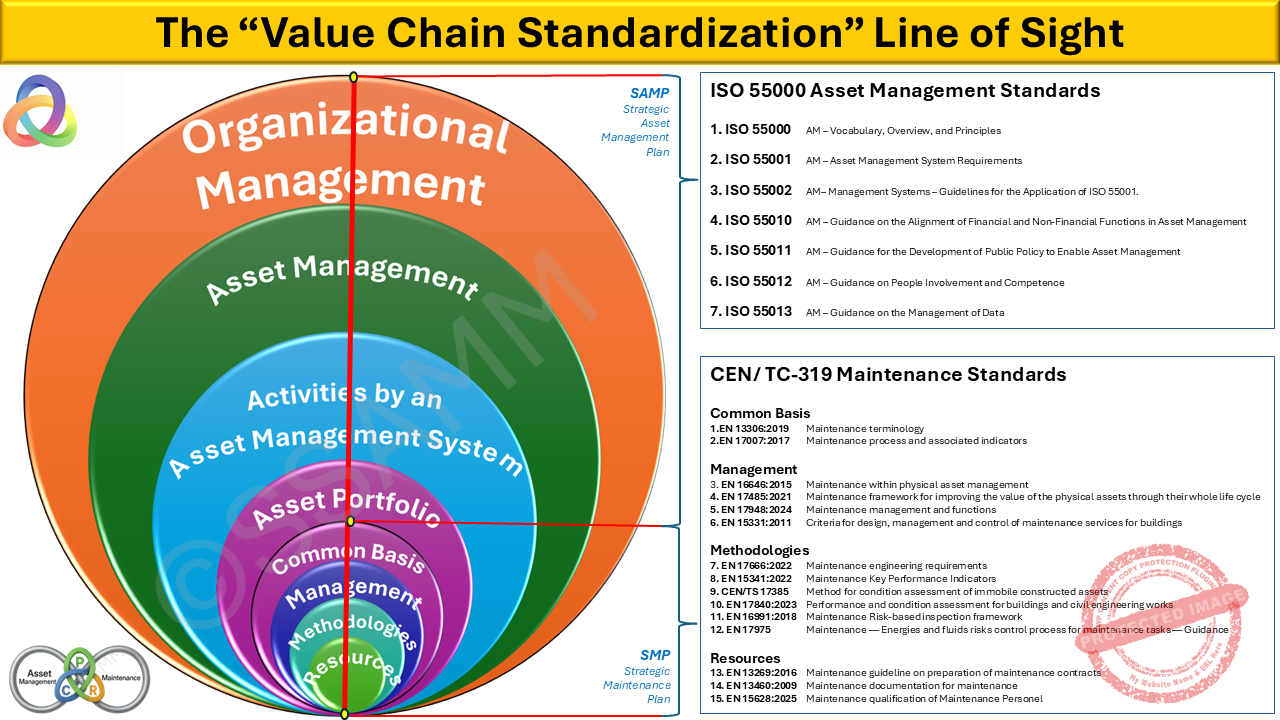

3. The VCS Line of Sight: a layered architecture

The VCS Line of Sight model visualises the A&MM value chain as a layered structure. At the top sits organisational management, where mission, public value, regulatory obligations and risk appetite are defined. Here, the main references are ISO 55000, ISO 55010 and ISO 55011, which together articulate how Asset Management contributes to organisational and societal objectives, and how financial and non-financial functions should be aligned.

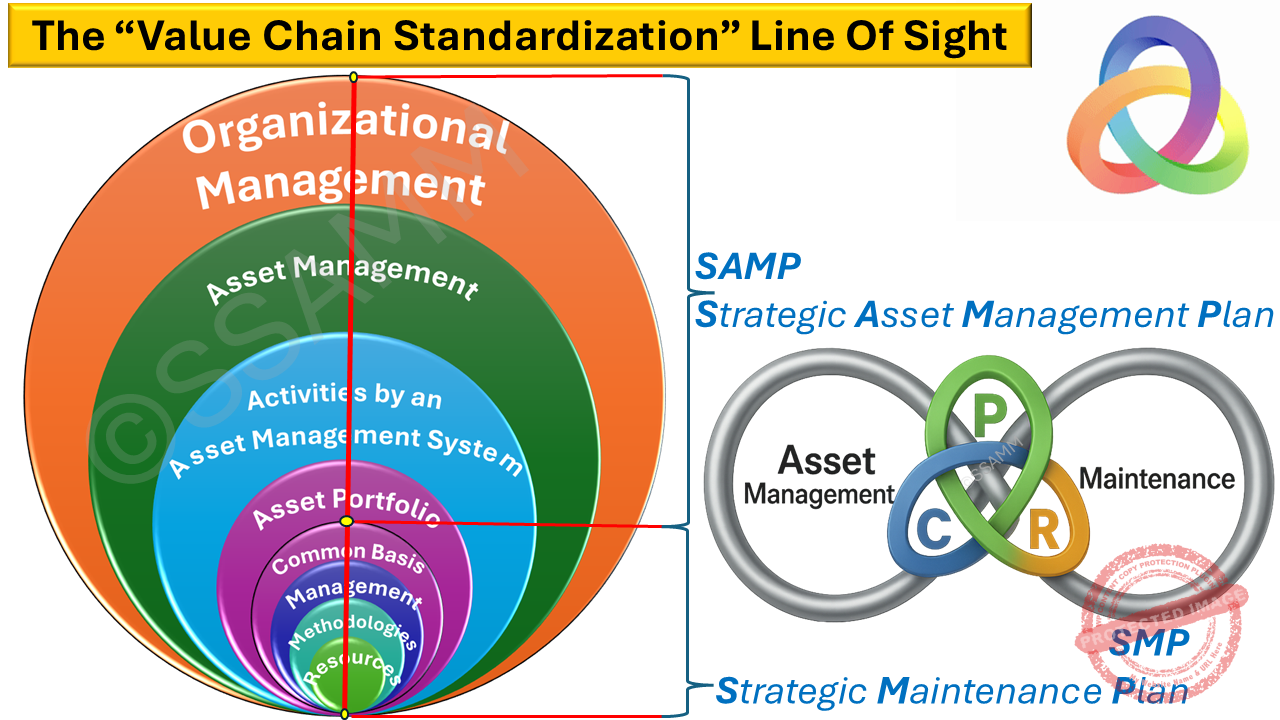

Below this lies the Asset Management layer, where these objectives are translated into asset-related objectives, strategies and investment priorities. The Strategic Asset Management Plan (SAMP) occupies a central place here and is governed by ISO 55001 and ISO 55002. It expresses how value and risk will be managed over the asset life cycle.

At the interface between Asset Management and Maintenance, the model introduces the Strategic Maintenance Policy (SMP) as a crucial governance element. The SMP translates SAMP intentions into maintenance principles, preferred concepts, priorities and expectations. It specifies, for example, how performance, cost and risk are to be balanced for different asset classes, which maintenance concepts are preferred, and how roles and responsibilities between Asset Management, operations, maintenance, engineering and suppliers are allocated. In the VCS model, the SMP is explicitly placed on the line of sight as the hinge between the ISO-based AMS and the CEN/TC 319-based maintenance system.

The lower half of the visual is devoted to the maintenance value chain, structured into four concentric “rings” that capture the logic of the CEN/TC 319 standards:

- A Common Basis of terminology and process architecture, provided mainly by EN 13306 and EN 17007.

- A Management layer, where standards such as EN 16646, EN 17485, EN 17948 and EN 15331 define how maintenance is positioned, governed and integrated into physical Asset Management.

- A Methodologies layer, containing standards like EN 17666, EN 15341, EN 16991, EN 17840, CEN/TS 17385 and EN 17975, which provide methods for maintenance engineering, risk-based inspection, condition assessment and KPI structures.

- A Resources layer, consisting of EN 13269, EN 13460 and EN 15628, which define the contractual, documentary and competence infrastructure needed to apply maintenance processes and methods consistently.

Across all these layers runs a vertical line of sight: a path along which one can trace how organisational objectives and risk criteria flow down into maintenance strategies, programmes and tasks, and how data, experience and assurance evidence flow back up into dashboards, risk evaluations, policy updates and strategic decisions.

At each layer, there is also a horizontal line of sight: coherence between functions and actors at the same level. At strategic level this means alignment between management, finance, risk and policy; at AMS level, between planning, information management and assurance; at maintenance level, between planning, engineering, execution, contracting, documentation and competence management, including external partners.

The VCS Line of Sight thus provides both a structural map of where standards sit and a conceptual spine that shows how they need to work together.

The P-C-R Trefoil

4. Integration with frameworks

The VCS architecture does not stand alone. It is designed to integrate and make visible a set of frameworks that many practitioners will already recognise.

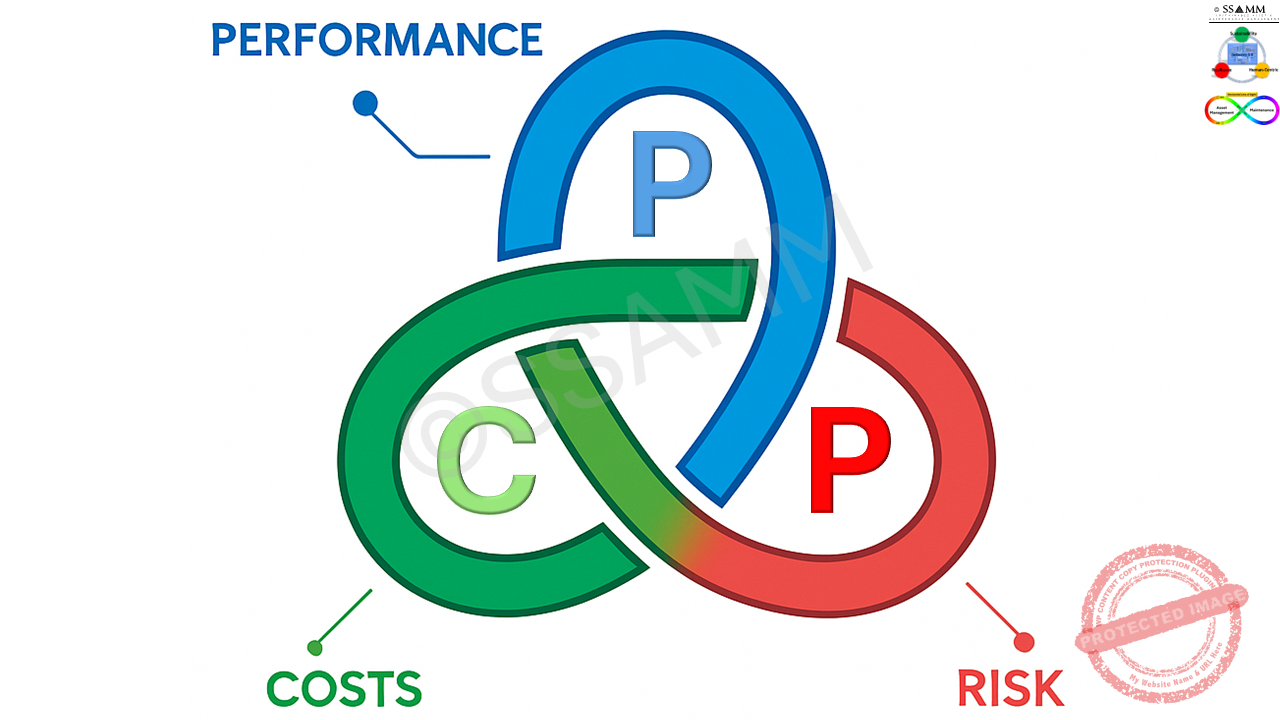

The P–C–R Trefoil Balance is used as the recurring decision compass along the line of sight. Performance, cost and risk are treated as entangled variables that must be balanced at strategic, tactical en operational levels. By placing the trefoil at multiple points in the architecture – at organisational management, in the SAMP, in the SMP and in maintenance programmes and methods – the model encourages organisations to standardise not only their structures, but also their decision logic.

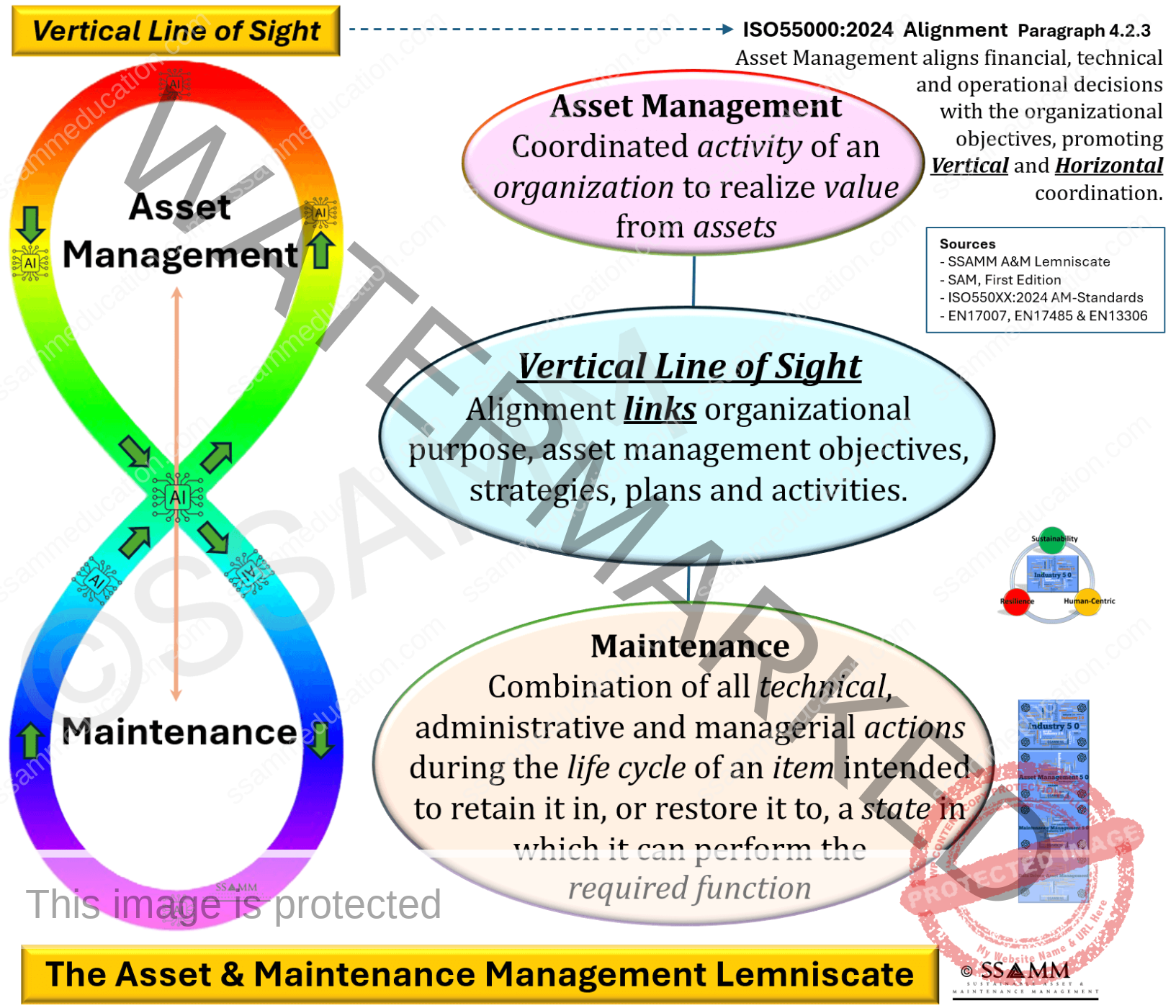

The A&MM Lemniscate Cornerstones describe the dynamic loop between Asset Management and Maintenance: strategy and planning on one side; preparation, execution, monitoring en feedback op de andere. The VCS Line of Sight can be seen as the vertical axis that runs through this lemniscate, providing a stable structure through which decisions and feedback travel each time the organisation moves around the loop.

The Maintenance Framework takes the CEN/TC 319 standards and turns them into a process-level blueprint for maintenance. It uses EN 17007 as the backbone for maintenance process architecture, and positions other standards as enablers of specific processes and functions. In the VCS model, the Maintenance Framework is the operational realisation of the lower part of the architecture.

Finally, the ISO550XX:2024 Insights & Overview interpretation provides the top-level context. It emphasises that the revised ISO 55000 series is not a checklist, but a set of principles around value, alignment, leadership, assurance and continual improvement. This lens keeps the VCS architecture oriented towards realising value and strengthening assurance, not merely towards satisfying formal compliance.

By integrating these elements, the VCS Line of Sight turns abstract standards and internal models into a coherent, living system that organisations can design, use, audit and refine.

5. Implications for roles and practice

Although the VCS Line of Sight is an architectural model, its relevance becomes most visible when viewed from the perspective of concrete roles.

For the Asset Manager, the model clarifies that the SAMP is not the end of the story. It must connect downwards to the SMP and to the maintenance value chain described by CEN/TC 319. The Asset Manager gains a way to articulate how portfolio and programme choices depend on the availability of engineering methods, data and competences, and how trade-offs between performance, cost and risk propagate through the chain. The architecture supports more

structured dialogue with finance, operations and maintenance about what is realistic, what is needed and where capability gaps exist.

For the Maintenance Manager, the VCS Line of Sight offers a way to make sense of the multitude of demands directed at maintenance. Instead of being the place where unresolved tensions between performance, cost and risk simply land, maintenance becomes a governed function with an explicit position in the value chain. The Common Basis, Management, Methodologies en Resources layers show how planning, engineering, execution, contracting, documentation and competence management fit together and how they relate to the SAMP and SMP. This helps the Maintenance Manager to argue for resources, to justify priorities and to embed continuous improvement in a way that is traceable along the line of sight.

For Maintenance Engineers and Reliability Engineers, the architecture shows that their methods are not stand-alone technical tools. Risk-based inspection, condition assessment, KPI frameworks and optimisation models occupy specific positions in the VCS model and carry the responsibility of making P–C–R decisions explicit, repeatable and explainable. Their analyses and recommendations must therefore support both local decisions and higher-level assurance. This perspective helps engineering roles to position themselves as system thinkers within the value chain.

For designers and maintainability specialists, the VCS Line of Sight underlines that maintainability is not a downstream afterthought. Design decisions about accessibility, modularity, monitoring and redundancy are, in effect, early-life P–C–R decisions that influence the entire future value chain. The architecture shows how these design choices will later be implemented in maintenance processes, data structures and competence frameworks, and how feedback from operation and maintenance can and should inform future design guidelines.

For those working on Industry 5.0, digitalisation and AI, the VCS model provides a stabilising backbone. Digital tools and analytics are only as powerful as the data structures and process architectures they rest on. By aligning data definitions with EN 13306 and EN 17007, and by designing information flows according to ISO 55013 and the CEN/TC 319 methodologies, organisations can ensure that digitalisation supports, rather than fragments, the value chain. Human-centricity and explainability – key themes in Industry 5.0 – are strengthened when digital solutions are embedded in a value chain that is structured, transparent and anchored in standards.

Finally, regulators, auditors and policymakers can use the VCS Line of Sight as a systemic lens for assurance. Instead of focusing on isolated documents or single standards, they can ask how vertical and horizontal line of sight are established and maintained, how standards are combined into one architecture, and how evidence from maintenance supports claims about value, affordability and risk in the long term.

Connecting the landscapes

6. Implementation, maturity and next steps

Implementing Value Chain Standardization is not a one-off technical exercise. It is a developmental journey that touches governance, processes, contracts, roles, data and culture. The full article proposes a phased approach, starting with diagnosis of fragmentation, through mapping current practices onto the VCS architecture, to designing and executing a realistic roadmap. Along this path, the SMP, the Maintenance Framework, competence development (inspired by EN 15628 and ISO 55012) and contract alignment (EN 13269, EN 13460) play important roles.

Over time, organisations can move from seeing standards as external requirements to treating them as a portfolio of internal assets that define their A&MM capabilities. The VCS Line of Sight then becomes part of the organisational learning system: each cycle through the A&MM Lemniscate provides feedback that can be used to refine the architecture, the SMP, the application of standards and the balance between performance, cost and risk.

For researchers and practitioners, the model also opens avenues for further work. Sector-specific variants of the VCS architecture, role-based curricula, digital line-of-sight concepts, maturity assessment tools and empirical case studies can all build on the foundation laid by this framework.